3-9

January 24, 2017

Basic Information

CLG835H

Universal tool, tooling list

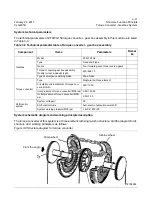

1) Wheel reducer: place the axle according to the installation position, and turn the hub to keep the oil

level in a horizontal position, fill oil from left and right hubs respectively until the oil overflows the oil

level plug; park the reducer for ten minutes after the drive axle running, and then check the oil level,

and add enough lubricating oil.

2) Axle housing: the oil is added into axle housing until it overflows from the oil filler.

The axle oil shall be replaced at the first 500h, after that once every 1000h, or at least once a year.

Universal tool, tooling list

For the universal tools, tooling list, please see the torque converter-gear box system, drive axle system

and drive shaft system.

Special tool, tooling list

For the special tool, tooling list, please see "ZF Box Overhaul Manual" for details.

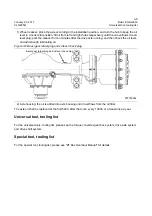

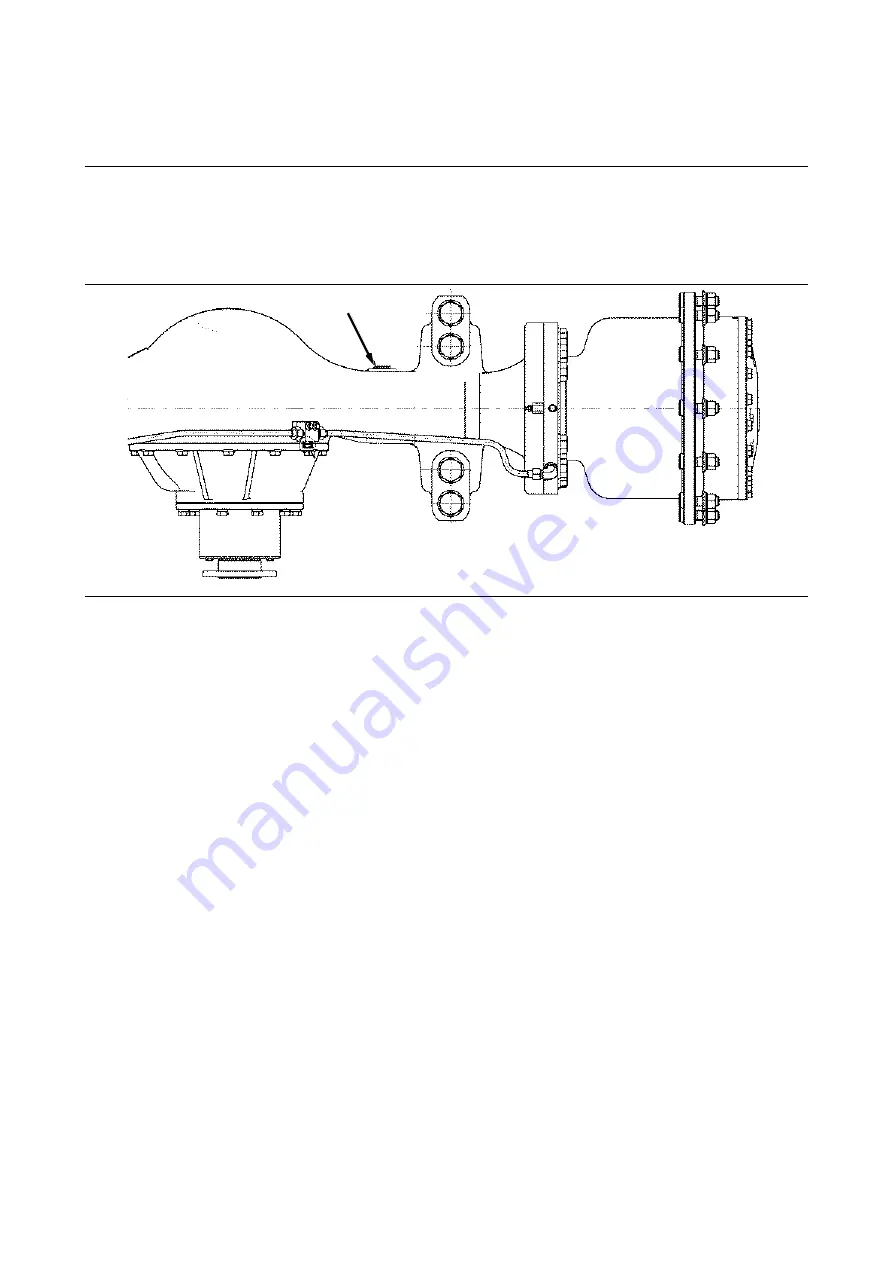

Figure 3-6 Bevel gear refuel plug and oil level check plug

Bevel gear refuel plug and oil level check plug

P18T00006

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

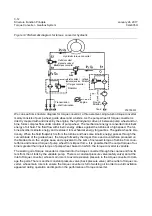

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...