3-36

Removal and Installation

January 24, 2017

Removal and installation of torque converter-gearbox system

CLG835H

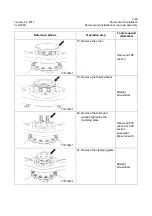

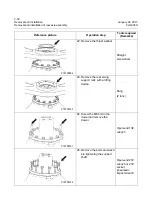

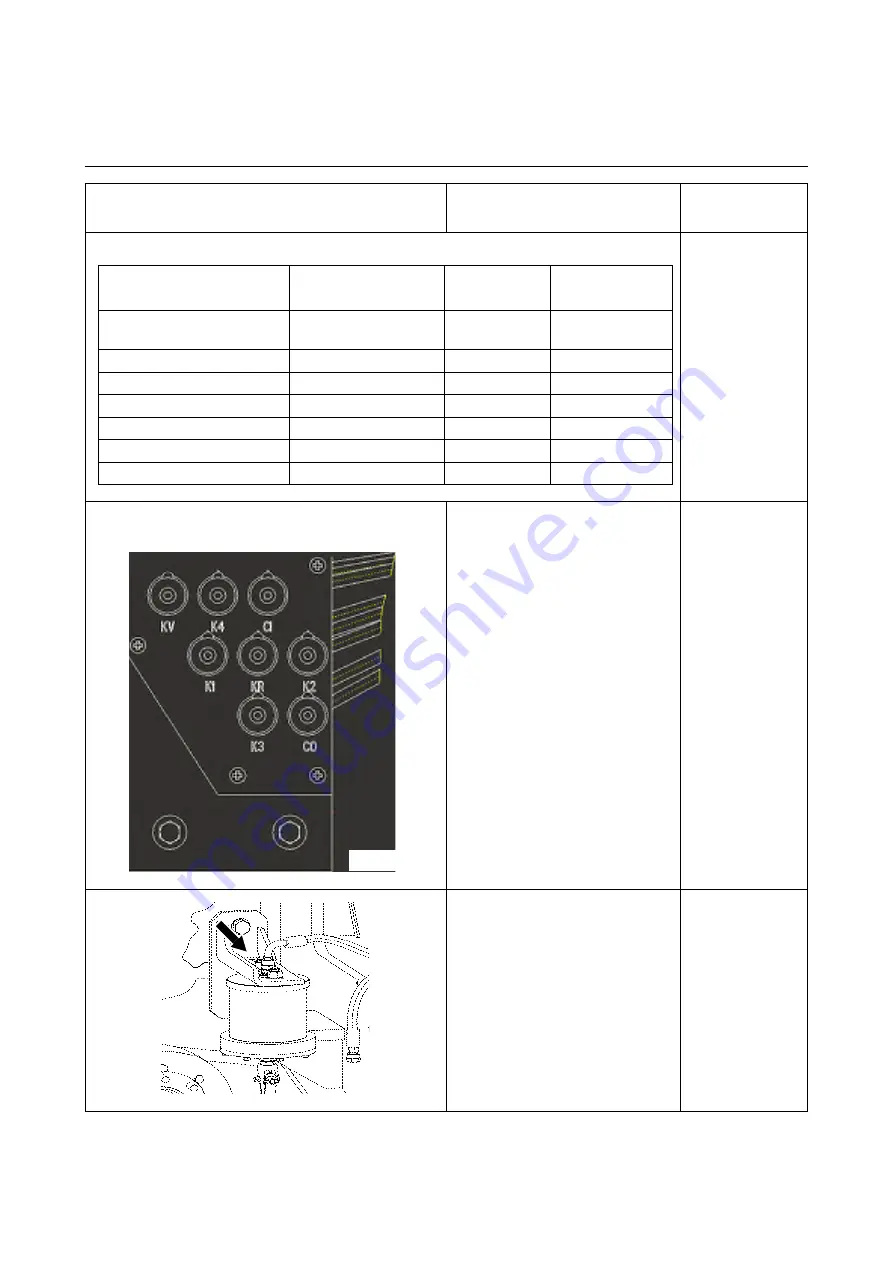

Logic diagram of test points and gear clutch

Mapping diagram of centralized measuring point

mounting plate and measuring point

15. Install the hose assembly

used for attaching emer-

gence parking brake cham-

ber to the brake system, the

tightening torque is

37±2Nm\ 27.29±1.48 lbf•ft.

24# wrench or

open-end 24#

fixed torque

spanner

Reference picture

Operation step

Tools required

(Remarks)

Decal marker

Meanings

Theoretical

value

S/N in the corre-

sponding valve

PRESSURE OF IN FRONT

OF THE CONVERTER

Inlet pressure of torque

converter

Opening pres-

sure: 1.1 MPa

51

PRESSURE OF KV CLUTCH KV clutch pressure

1.6-1.8MPa

53

PRESSURE OF KR CLUTCH KR clutch pressure

1.6-1.8MPa

55

PRESSURE OF K1 CLUTCH

K1 clutch pressure

1.6-1.8MPa

56

PRESSURE OF K2 CLUTCH

K2 clutch pressure

1.6-1.8MPa

57

PRESSURE OF K3 CLUTCH

K3 clutch pressure

1.6-1.8MPa

58

PRESSURE OF K4 CLUTCH

K4 clutch pressure

1.6-1.8MPa

59

P18T00063

P18T00064

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...