3-55

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of rear axle assembly

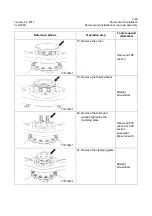

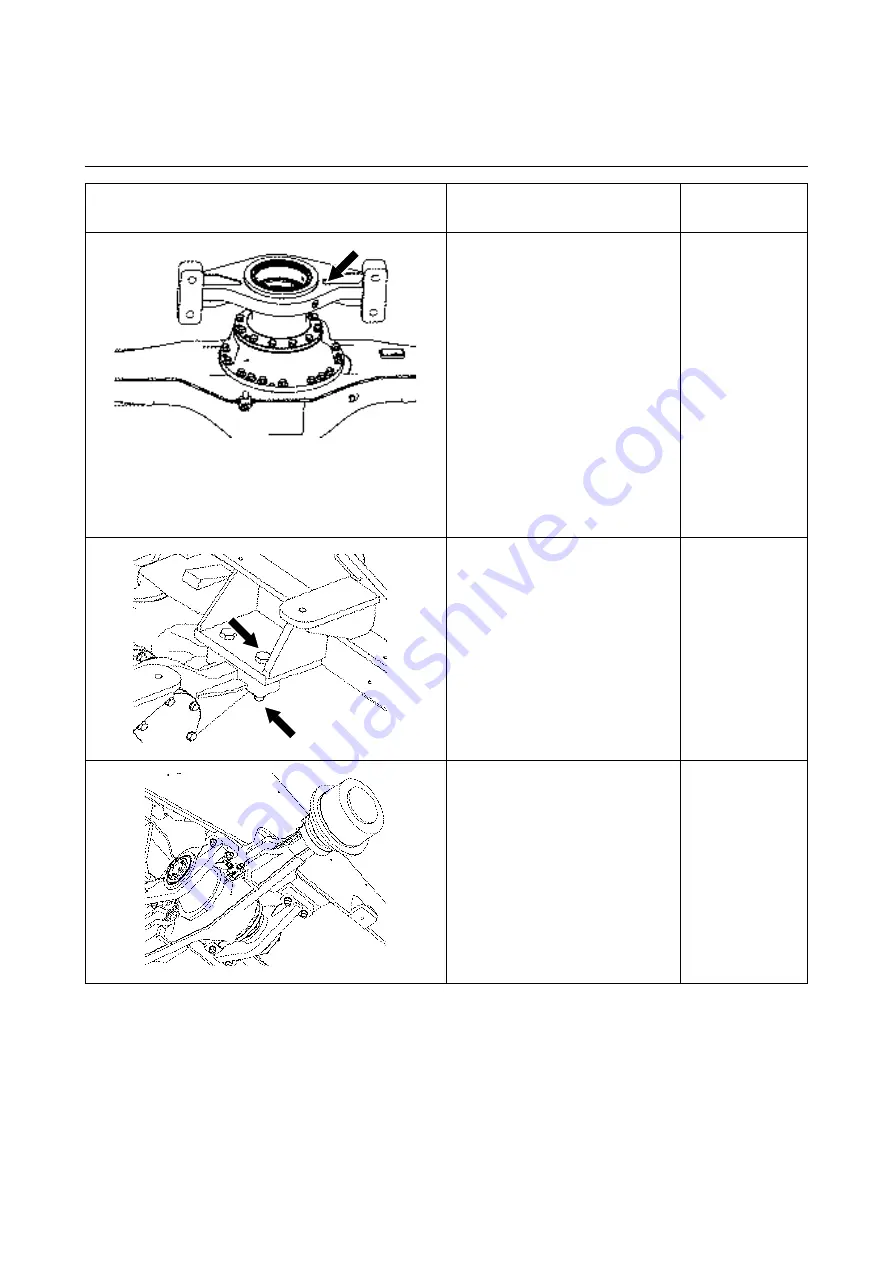

15. Evenly apply the molybde-

num disulfide lithium base

grease to bushing cone, and

then lift and install the front

swing support subassembly

onto the bearing seat of the

main transmission.

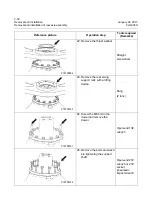

16. Place the axle assembly on

a transport device with a lift-

ing device, and right under

mounting point of rear axle.

17. Install the axle assembly

onto the rear frame with a

lifting device and align the

mounting holes.

Sling

(2 tons)

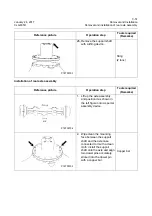

18. Install the mounting bolts,

washers and nuts of the axle

assembly and tighten them

with an blower gun to

1122±90Nm\ 827.28±66.38

lbf•ft.

36# socket,

pneumatic

impact wrench,

open-end 36#

fixed torque

spanner

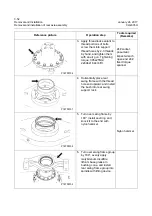

19. Install the axle and hose

connecting the service brake

pipe and tighten it to

37±2Nm\ 27.29±1.48 lbf•ft.

Open-end 24#

wrench

Reference picture

Operation step

Tools required

(Remarks)

P18T00118

P18T00119

P18T00120

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...