3-57

January 24, 2017

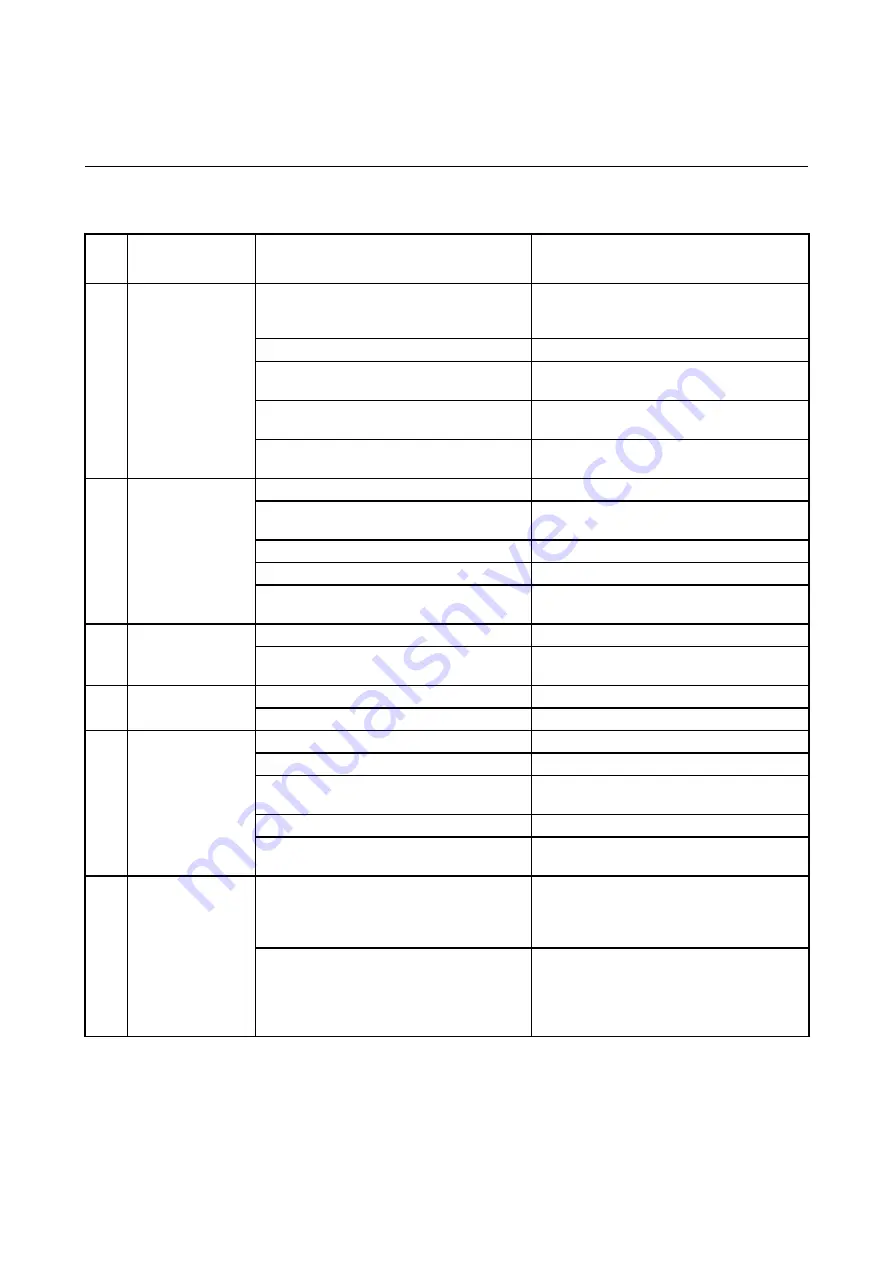

Fault Diagnosis and Troubleshooting Methods

CLG835H

Disassembly and assembly of the drive axle

Fault Diagnosis and Troubleshooting Methods

Fault features

Main reasons

Fault inspection and

troubleshooting

1

The engine can not

Activation

1. Start circuit of the base machine (such as

power voltage, electric lock, startup relay

and startup motor) has faults.

1. Check the circuit of the base machine.

2. The lever is not at the neutral position.

2. Shift the lever to neutral position.

3. The fuse to the control circuit on the base

machine is burnt.

3. Replace the fuse.

4. Poor contact of handle plug or the handle

is failed.

4. Organize the plugs.

5. Poor contact of controller plug or the con-

troller is failed.

5. Organize the plugs.

2

Low shift pressure

at all gears

Low pressure

1. Oil pressure gauge is failed.

1. Replace the oil pressure gauge

2. Insufficient tightening torque for bolt of

shift control valve.

2. Tightening torque for M8-8.8 bolt of shift

control valve is 26Nm.

3. Spring of main pressure valve is broken.

3. Replace it.

4. Gear shift pump is worn

4. Replace the gear shift pump.

5. Fragments enter into shift control valve or

valve is stuck

5. Replace the filter, and clean the control

valve.

3

Too short shifting

time at all gears

1. O-ring in throttle plug is damaged

1. Replace the O-ring

2. The tightening torque of pressure control

valve bolts is out of specified range

2. Tightening torque for M8-8.8 bolt of shift

control valve is 26Nm.

4

Too long shifting

time at all gears

1. Throttle plug is blocked.

1. Clean and dredge.

2. Pressure control valve is stuck.

2. Wash and check.

5

The oil tempera-

ture of the torque

converter is high

1. Oil temp sensor is failed.

1. Replace the part.

2. Oil temperature gauge is failed.

2. Replace the part.

3. Insufficient oil level.

3. Check oil level following the correct

method.

4. Air found in torque converter oil radiator.

4. Exhaust.

5. Oil line from torque converter to radiator is

poor.

5. Check oil pipe from radiator to gear box

and radiator for blockage.

6

The oil tempera-

ture of the torque

converter is high

1. Poor cooling capability of radiator.

1. Check whether cooling capability is suffi-

cient, such as checking the degree of

tightness for engine fan belt and dirt

attached to outer surface of radiator.

2. Back pressure valve of torque converter

stuck.

2. Be careful to check hose connector from

gear box to radiator. If hose connector

enters housing too deeply, pushes spool

of pressure valve and cause valve to stick,

oil line will be getting blocked.

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...