3-5

January 24, 2017

Basic Information

CLG835H

System schematic diagram and working principle description

System schematic diagram and working principle description

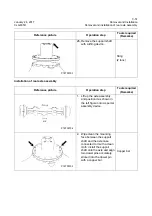

The torque converter -gearbox assembly equipped in this machine is ZF 4WG158 full auto type, and the

drive axle is 30 wet axle, whose structure diagram are shown as below:

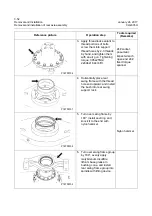

Tire

Tire structure

Radial tire

Tubeless bias tire or tubed bias

tire is optional

Specification

17.5R25 two star L3

Level

\

Type of tread

L-3

Ordinary block

Rim

Specification

25-14.00/1.5

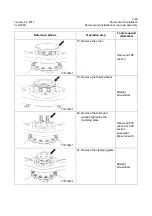

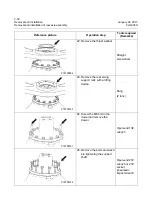

Figure 3-2 Diagram for gear box assembly composition

1. Coupling device

2. Torque converter housing

3. Lifting eye

4. Control harness interface

5. Electro-hydraulic shift control valve

6. Suction tube

7. Brake

8. Output plate

9. Nameplate

10.Output flange

11.Speed sensor

12.Oil outlet of torque converter

13.Torque converter outlet oil temperature sensor

14.Cover

Table 3-1: Main technical parameter table for power train system

System components

Items

Parameters

Remarks

1

2

3

3

5

6

7

8

9

10

11

12

13

14

4

P18T00002

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...