3-35

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of torque converter-gearbox system

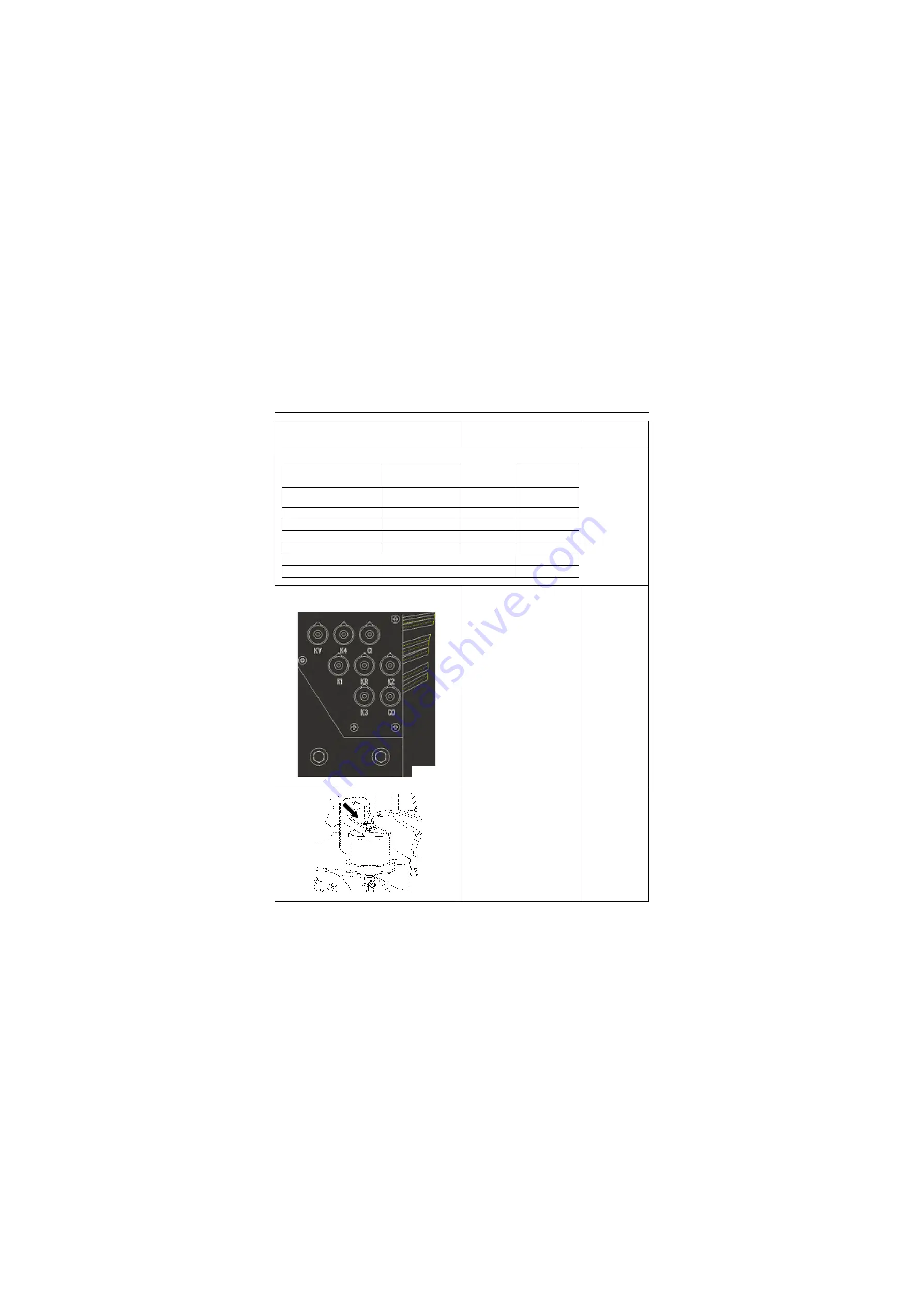

Logic diagram of test points and gear clutch

Mapping diagram of centralized measuring point

mounting plate and measuring point

15. Install the hose assembly

used for attaching emer-

gence parking brake cham-

ber to the brake system, the

tightening torque is

37±2Nm\ 27.29±1.48 lbf•ft.

24# wrench or

open-end 24#

fixed torque

spanner

Reference picture

Operation step

Tools required

(Remarks)

Decal marker

Meanings

Theoretical

value

S/N in the corre-

sponding valve

PRESSURE OF IN FRONT

OF THE CONVERTER

Inlet pressure of torque

converter

Opening pres-

sure: 1.1 MPa

51

PRESSURE OF KV CLUTCH KV clutch pressure

1.6-1.8MPa

53

PRESSURE OF KR CLUTCH KR clutch pressure

1.6-1.8MPa

55

PRESSURE OF K1 CLUTCH

K1 clutch pressure

1.6-1.8MPa

56

PRESSURE OF K2 CLUTCH

K2 clutch pressure

1.6-1.8MPa

57

PRESSURE OF K3 CLUTCH

K3 clutch pressure

1.6-1.8MPa

58

PRESSURE OF K4 CLUTCH

K4 clutch pressure

1.6-1.8MPa

59

P18T00063

P18T00064

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...