3-40

Removal and Installation

January 24, 2017

Removal and installation of drive shaft system

CLG835H

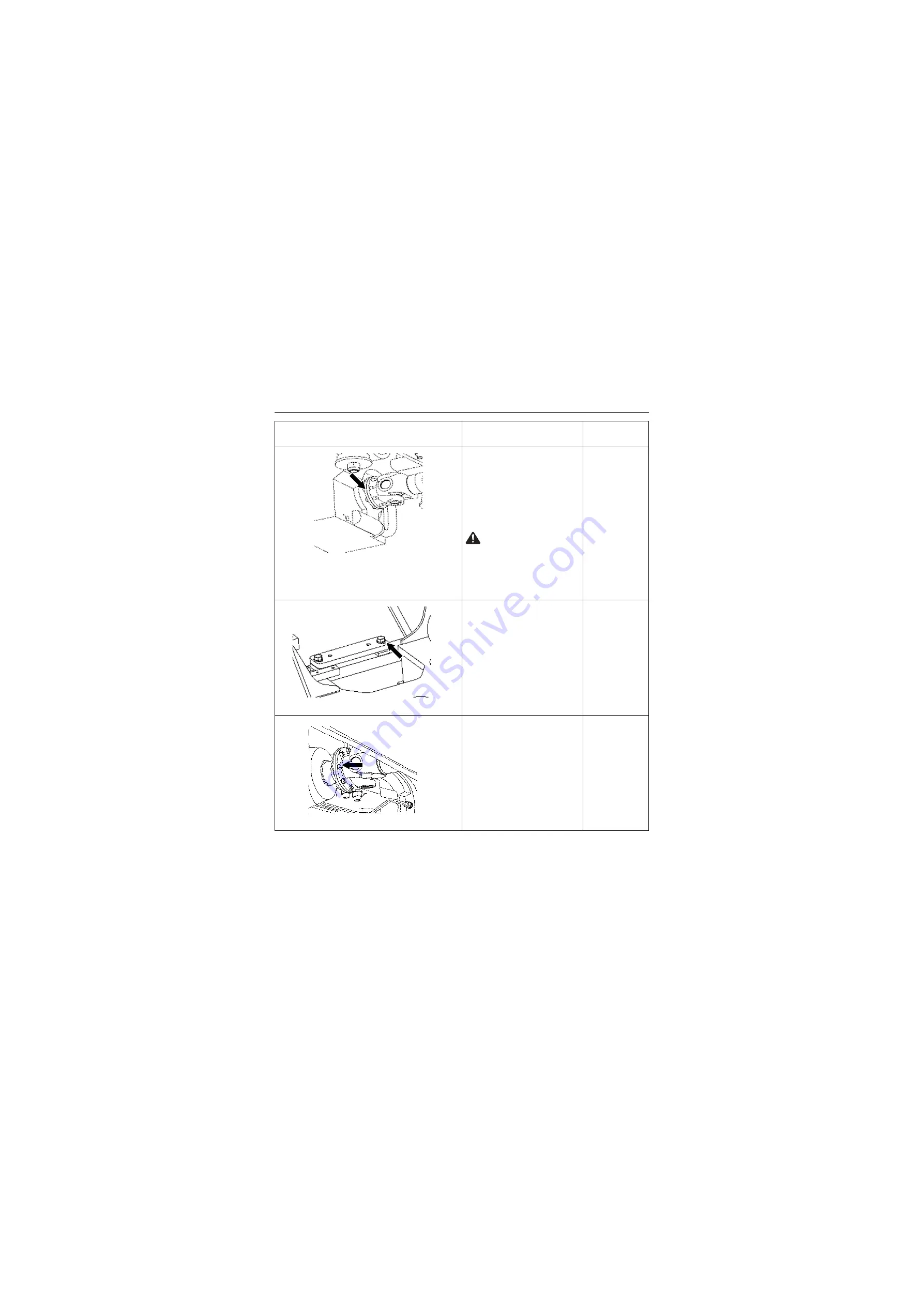

2. Wipe clean the surface,

install the rear drive shaft

and rear output flange of the

gear box, and align the

mounting holes, screw in the

locknut and tighten it with a

torque of 132±10Nm\

97.35±7.38 lbf•ft.

Caution: When assem-

bling, please make sure

to pay attention to the white

arrows on the identification of

drive shaft, both of which

must be aligned after assem-

bly!

18# wrench or

open-end 18#

fixed torque

spanner

3. Wipe clean the two mount-

ing surfaces of support

plates, and then pre-install it

onto the front frame. Set the

front drive shaft and support

assembly with middle sup-

port bearing on the front

frame middle support bear-

ing seat support plate.

4. Wipe clean the surface,

install the front drive shaft

and support assembly with

front axle input flange, and

align the mounting hole,

screw in the locknut and

tighten it with a torque of

132±10Nm\97.35±7.38 lbf•ft.

18# wrench or

open-end 18#

fixed torque

spanner

Reference picture

Operation step

Tools required

(Remarks)

P18T00073

P18T00074

P18T00075

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...