3-58

Testing and adjustment

January 24, 2017

Power Train Test

CLG835H

Testing and adjustment

Power Train Test

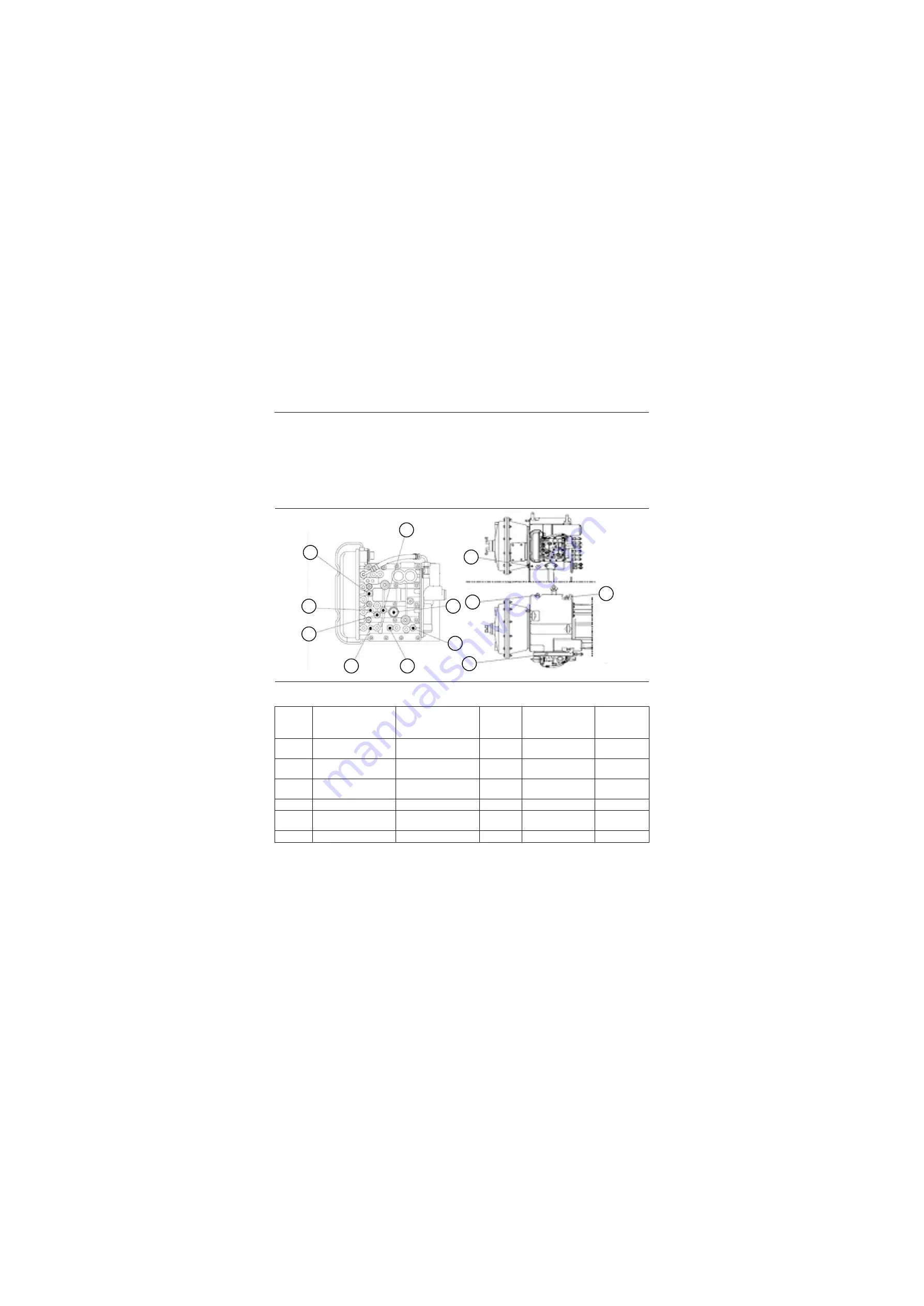

Detection point layout of torque converter - gear box assembly as is shown in Figure 3-25, and names

and parameters of each detection point can be found in Table 3-7.

Table 3-7 Parameter list of the measuring point

Logical relations between gear states and working conditions of shift control valve solenoid valve can be

found in Table 3-8.

Figure 3-25 Measuring point layout

S/N of the

measur-

ing point

Name of the measuring

point

Theoretical value

S/N of the

measuring

point

Name of the

measuring point

Theoretical

value

21

Input sensor of the gear

box

\

55

Reverse gear clutch

1.6-1.8MPa

34

Output sensor of the

gear box

\

58

Gear 3 clutch

1.6-1.8MPa

51

Inlet pressure of torque

converter

Opening pressure: 0.85

56

Gear 1 Clutch

1.6-1.8MPa

53

Forward gear clutch

1.6-1.8MPa\232-261psi

57

Gear 2 Clutch

1.6-1.8MPa

65

Pressure of shift control

system

1.6-1.8MPa\232-261psi 63

Outlet pressure of

torque converter

Opening

pressure: 0.5

60

Gear 4 Clutch

1.6-1.8MPa\232-261psi

53

58

65

55

60

56

57

66

51

21

63

34

P18T00123

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...