4-20

Structure Function Principle

January 24, 2017

Work hydraulic system

CLG835H

In which, the oil return chamber is used to

temporarily store the hydraulic oil that returns

from the system to effectively reduce the back-

flow velocity so as to avoid bubbles in the

hydraulic oil tank resulted from too fast oil return.

The oil return filter mainly filters the oil returning

to the hydraulic oil tank to prevent pollutant from

entering into the system through the oil tank to

cause pollution. The baffle is used to form

isolation circulation for cold and hot oil in the oil

tank to prevent oil shake from generating large

quantities of bubbles and isolate oil suction port

from oil return port to ensure gas separates out

of hydraulic oil return. Washing port is used to

clean the dirt in the oil tank. Oil drain hole is used

to drain fluid out of oil tank when replace oil or

clean oil tank. Oil suction port is used to supply

oil for hydraulic pump. The ventilated oil conduit

is used for exhalation of a breather and to lead

the oil vapor exhaled by the breather to

underbody. Hydraulic oil is filled from the oil filler

after filtration by the oil filter vehicle. Oil filler filter

element is used to prevent large particles from

entering into oil tank when replacing and filling

hydraulic oil. The function of the breather is that it

sucks air from atmosphere to fill the air space

when the air pressure in oil tank is negative and

that exhaust extra air to realize the protection

function when the air pressure in oil tank is out of

limit. Oil level gauge is used to observe the oil

level of oil tank. Oil suction port is used to supply

oil for hydraulic pump.

Plunger pump

Main technical parameters

Structure and working principle of plunger

pump

Same pump is used for the plunger pump of work

hydraulic system and that of steering hydraulic

system, that is, work hydraulic system and

steering hydraulic system share one pump. The

plunger pump is located under cab and installed

on the right power take-off of the transmission

and tightened it by stud and nut. It is driven by

engine via torque converter and transmission to

supply oil for work and steering hydraulic system.

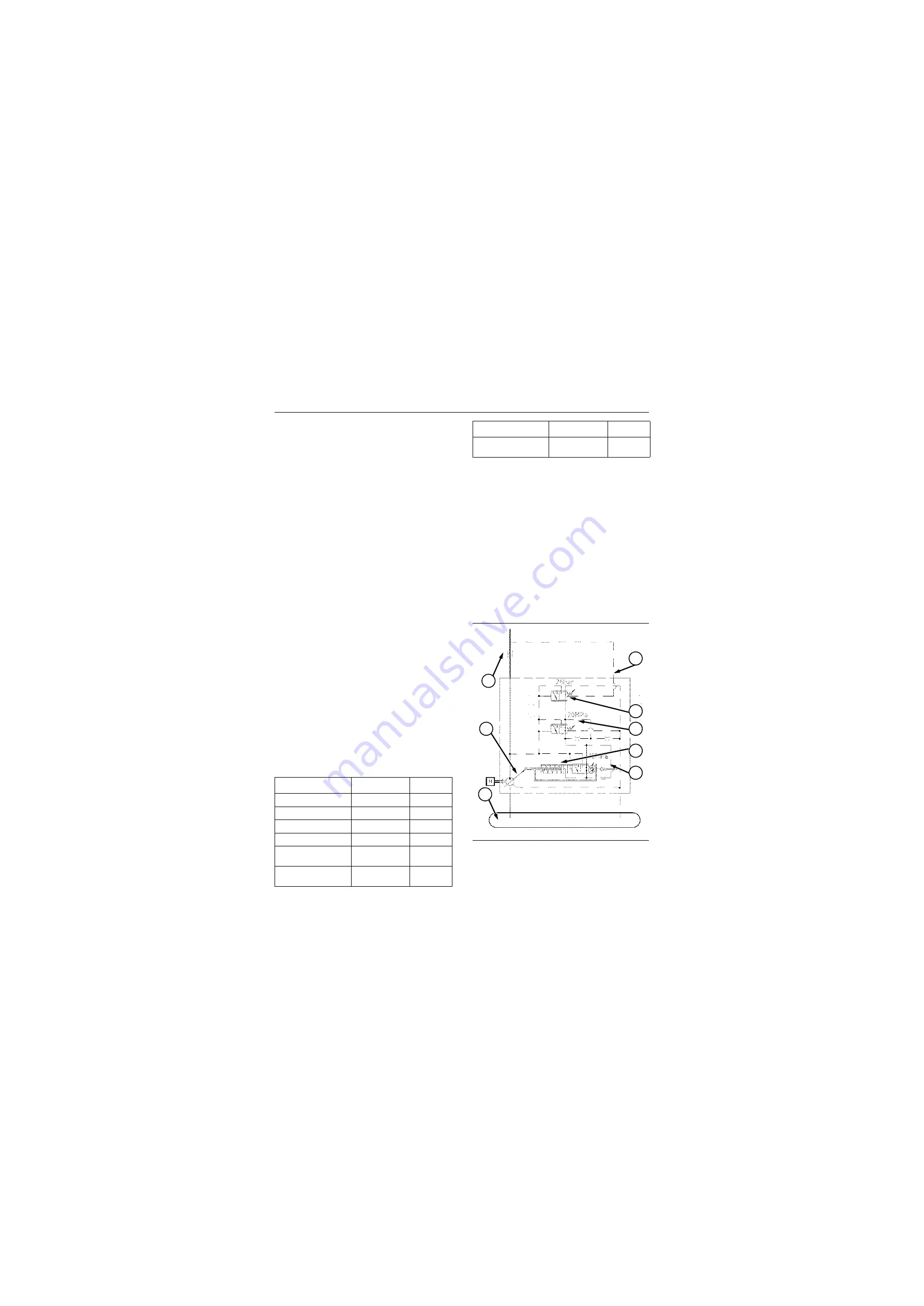

Outline diagram and working principle of

plunger pump:

Items

Parameters

Remarks

Rated pressure

19Mpa\ 2755psi

Displacement

100ml/r\ 100cc/r

Direction of rotation

Left rotation

Rated speed

2200rpm

Pressure of the shut-

off valve

20Mpa\ 2900psi

Pressure of flow

compensator valve

2.6Mpa\ 377psi

Operating fluid

Anti-wear

hydraulic oil

46#

Schematic of working pump

1. Hydraulic oil tank

2. Swashplate

3. Control valve (simpli-

fied)

4. Load sensing port

5. Flow compensation

valve

6. Pressure shut-off valve

7. Variable cylinder

8. Power control valve

Items

Parameters

Remarks

P18H00011

2

3

4

5

7

8

6

1

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...