4-177

January 24, 2017

Removal and Installation

CLG835H

Steering hydraulic system

Inspection and cleaning of steering cylinder

Figures

Operation instruction

Tools

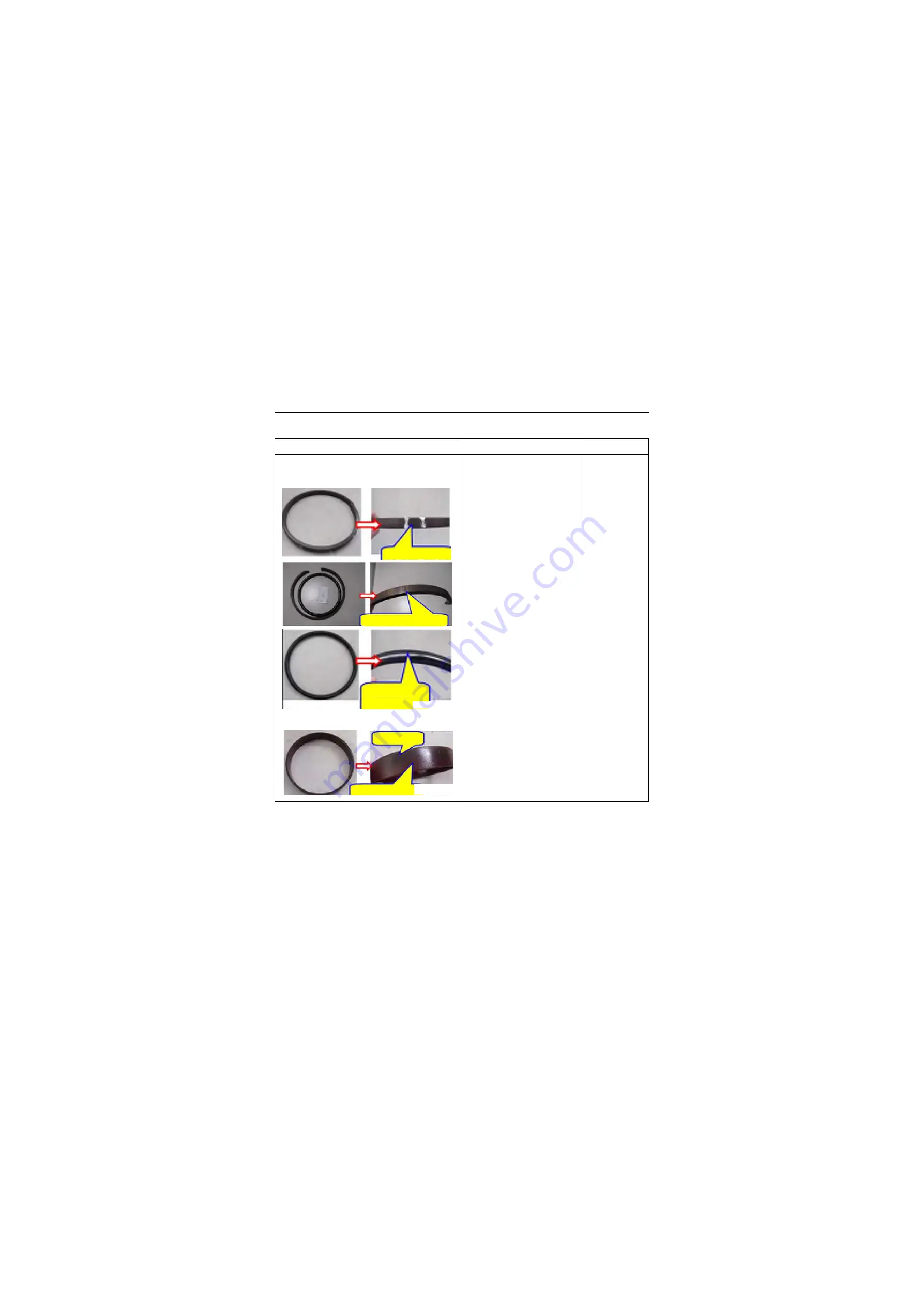

Piston group picture:

Figure 1

Figure 2

Cleaning of part:

Clean cylinder block, piston rod,

cylinder head and piston using

kerosene and detergent, and

then dry all parts with

compressed air.

Inspection of part:

1. Inspection of piston group:

1) Inspection of piston seal:

a) Check whether glyd ring

is scratched, worn,

extruded and collapsed

(Figure 1).

b) Check whether support

ring is scratched,

strained, worn and burnt

(Figure 2).

c) Check whether O-ring at

static seal of piston is

worn and trimmed.

2) Inspection of piston:

a) Check whether contour

of piston is scratched

and strained (Figure 3).

b) Check whether two end

surfaces are com-

pressed seriously.

P18H00266

O-ring surface shows

roughness and wear

Friction ring outer circle has scratch,

and one side angle has defects

Friction ring outer circle

has scratch

P18H00267

Complete ring outer

circle grows black

With light wear and scratch partially

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...