4-203

January 24, 2017

Removal and Installation

CLG835H

Brake system

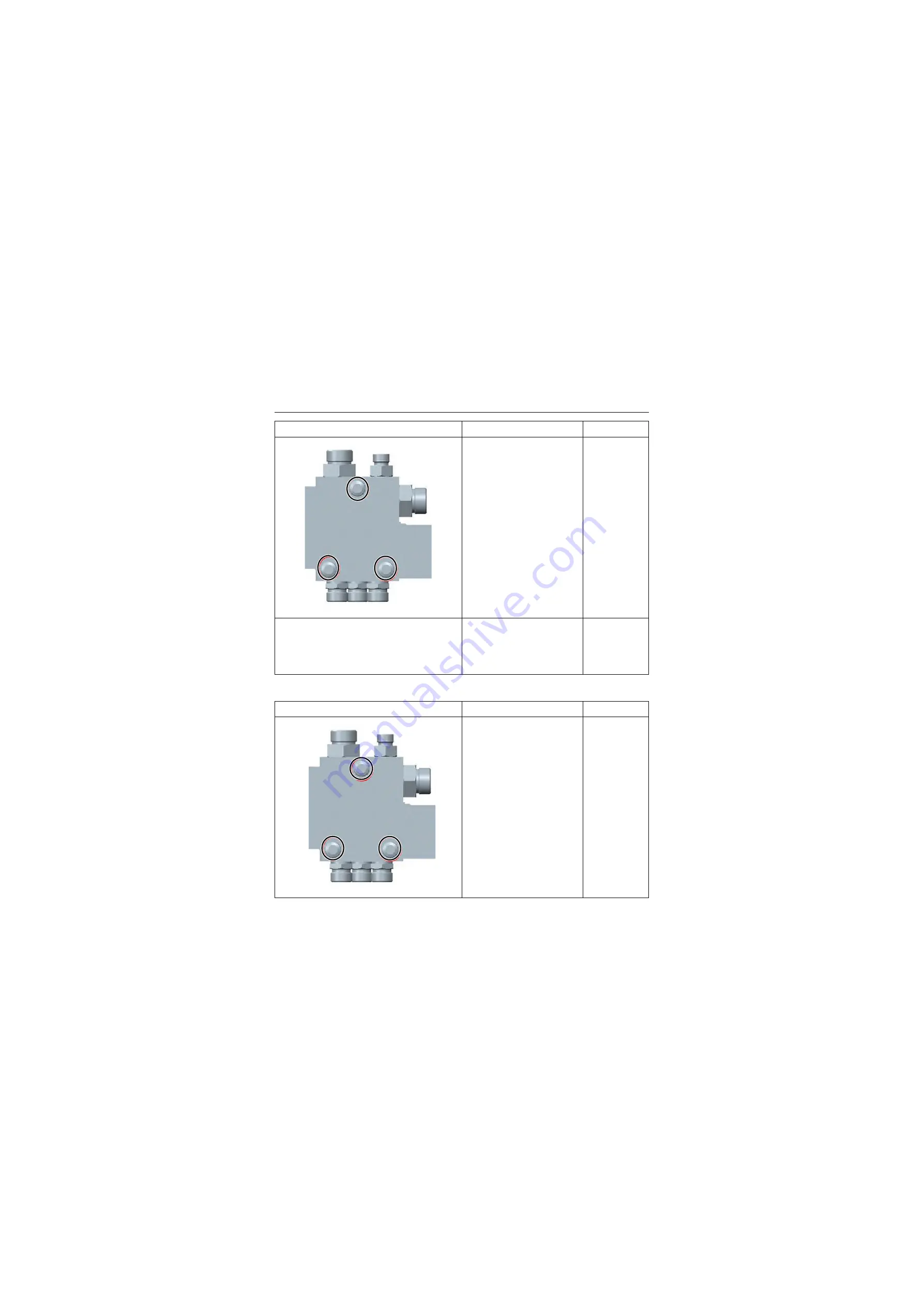

Installation of charge valve

3. Unscrew the 3 bolts tighten-

ing the charge valve;

Open-end

wrench:

8mm

4. Take the charge valve out of

left housing;

5. Shield the joint of charge

valve and store it in dry and

clean place.

Figures

Operation instruction

Tools

P18H00316

Figures

Operation instruction

Tools

1. Tighten bolts, install the

charge valve onto the

mounting plate of left box,

tightening torque of bolts:

10.5±1.5Nm\ 7.7±1.1lbf·ft;

Open-end

wrench:

8mm

P18H00317

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...