4-228

Removal and Installation

January 24, 2017

Brake system

CLG835H

Assembly of solenoid directional valve

Figures

Operation instruction

Tools

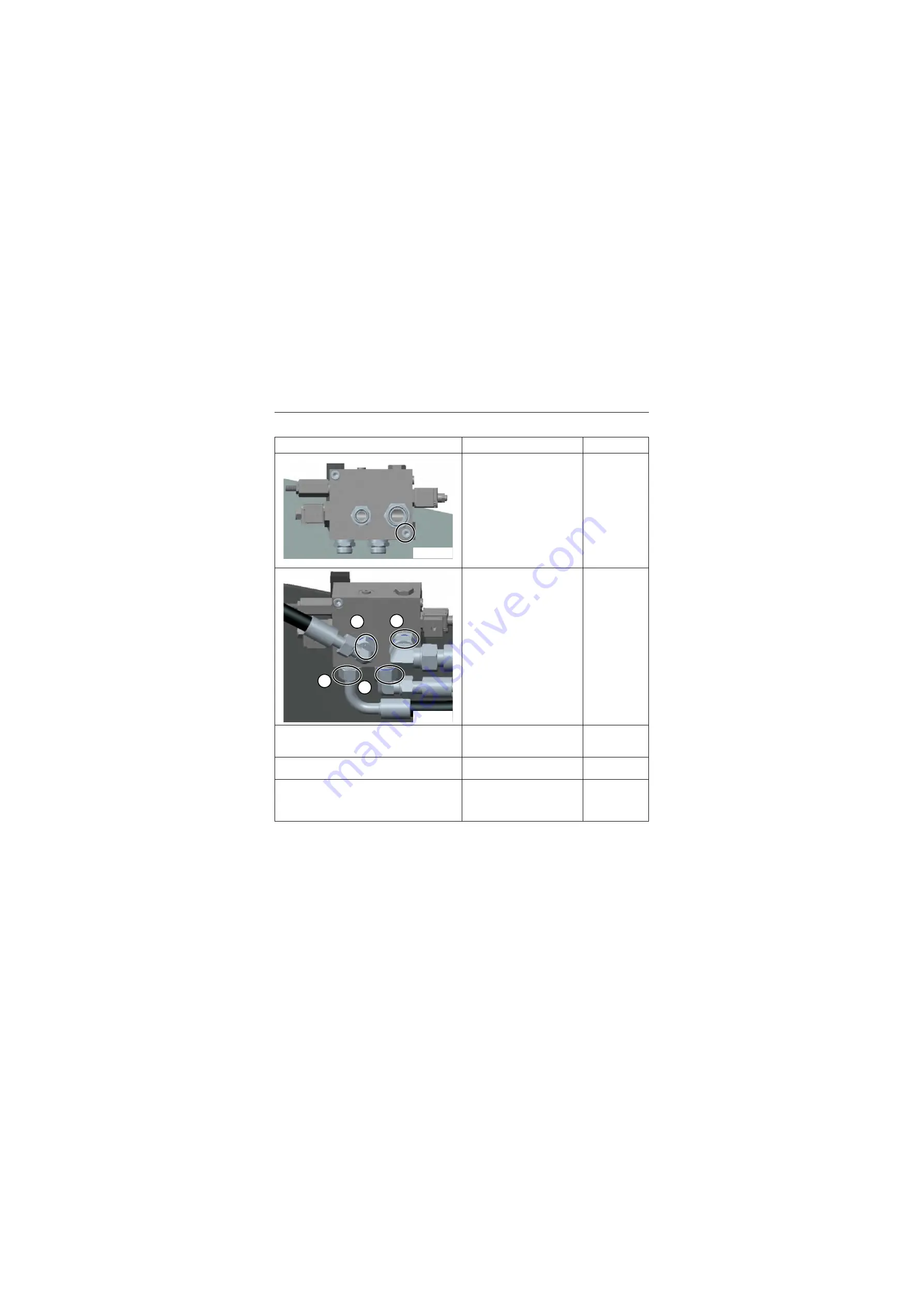

1. Install the solenoid direc-

tional valve to its original

position and tighten 2 bolts

to 52±6Nm\ 38.4

±

4.4lbf

·

ft

2. Connect the T hose with the

tightening torque of hose

joint 137±6Nm\ 101±4.4lbf·ft

3. 3Connect hoses of B port, A

port and P port and the tight-

ening torque of hose joints is

89±4Nm\ 65.6±3.0lbf·ft

4. Fill the hydraulic oil, start the

machine and idle it for 5min

to bleed the air in the line

5. Stop the machine and check

it for leakage.

6. Check whether the hydraulic

oil level is normal, and if not,

please fill the hydraulic oil to

the specified level

P18H00368

P18H00365

B

P

T

A

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...