5-33

January 24, 2017

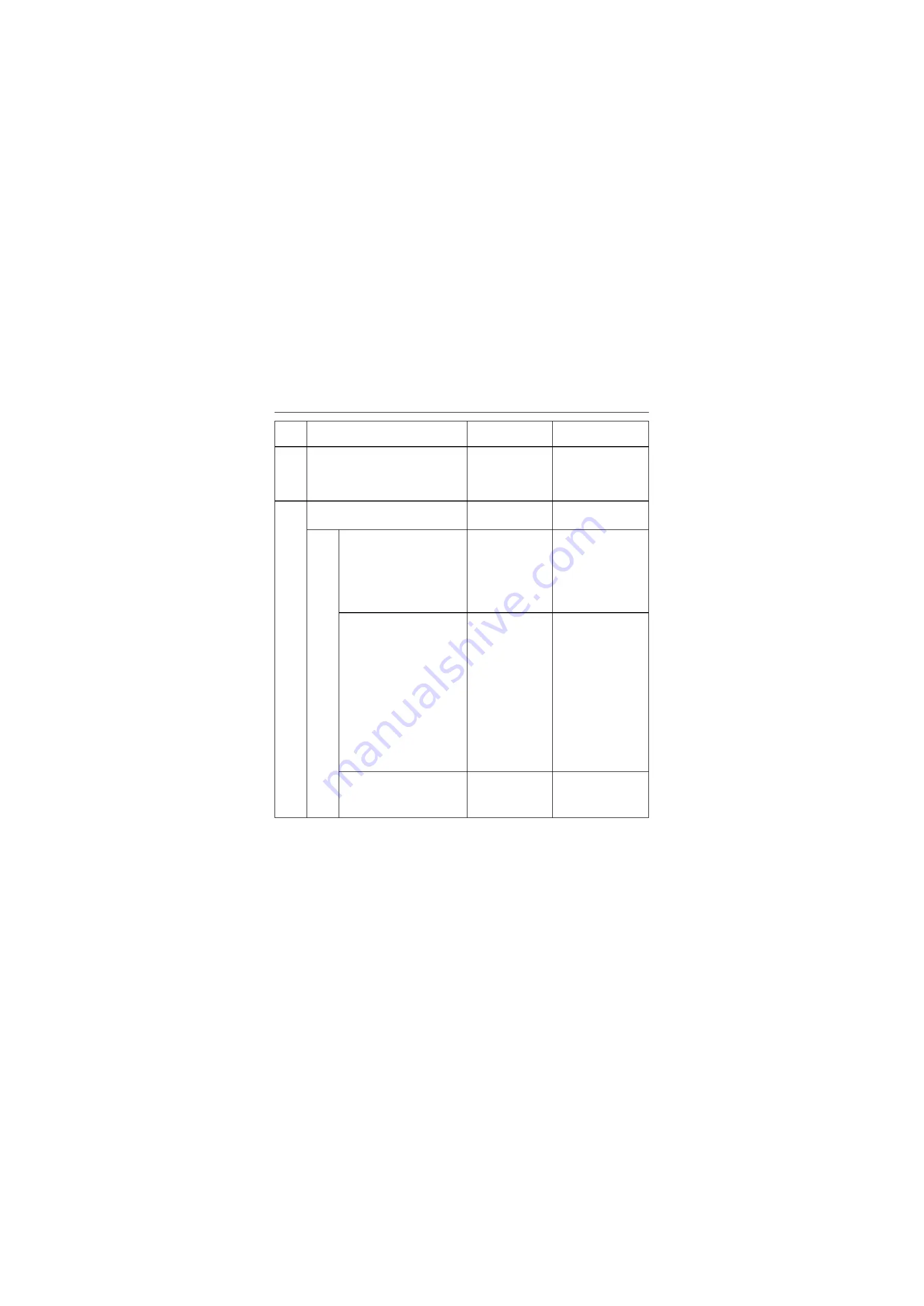

Fault Diagnosis and Judgment

CLG835H

Overhauling method

Items

Fault conditions

Cause

Troubleshooting meth-

ods

1

Air bubbles persistently exist in sight glass, com-

pressor air intake hose joint is not cold enough

and even warm, the upper end and lower end of

reservoir do not have temperature difference, and

temperature is higher than or equal to ambient

temperature

Refrigerant leakage.

Insufficient refrigerant fill-

ing amount.

Check and repair leakage

parts, and refill refrigerant.

Refer to A/C Refrigerant Fill-

ing Method

2

Compare the pressures of air conditioning system

operating at high and low pressures with normal

pressures (see table attached hereinafter)

Pres

sur

e

of

low pr

essure

sid

e

a

nd hig

h pressure

si

de are bo

th

lo

w

1. Normally refrigerate for several min-

utes, stop refrigerating for several

minutes, and normally refrigerate for

several minutes…repeat like this.

2. Compressor is operating continu-

ously.

3. The pressure at the beginning of

refrigeration is normal, and pressures

at low pressure side and high pres-

sure side when refrigeration stops

are obviously low.

There is too much water

in refrigerating system to

cause ice blockage in

expansion valve (orifice is

frozen due to water accu-

mulation to block orifice)

Replace reservoir, vacuum

pumping for more than 1 h,

and fill refrigerant once again

as specified in Removal and

Installation of A/C Compo-

nents

1. Touch compressor air intake hose

joint (thick joint) by hand to feel no

coldness.

2. There are no big differences in tem-

perature of the high temperature

zone and the low temperature zone

of a condenser.

3. The temperature of each part of res-

ervoir is basically the same to that of

condenser outlet and close to ambi-

ent temperature.

The interior part of refrig-

erating system is very

dirty, and the expansion

valve orifice is blocked by

dirt

1. Switch on refrigeration for

about 1 minute and switch

off refrigeration for about

3~5 minutes with doors

and windows open under

high engine speed (engine

can be at idle speed but air

volume shall be in highest

position), then step on

accelerator to refrigerate

for about 1 minute…repeat

like this for three times so

that contamination and

blockage may be elimi-

nated.

2. If the above methods are

ineffective, clean or

replace expansion valve; If

gray black or brown black

color appears in sight

glass, please make sure to

replace reservoir.

The expansion valve con-

trol head leaks and the

valve hole switches

smaller automatically

Replace the expansion

valve; If gray black or brown

black color appears in sight

glass, please make sure to

replace reservoir.

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...