7-15

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of hinge assembly

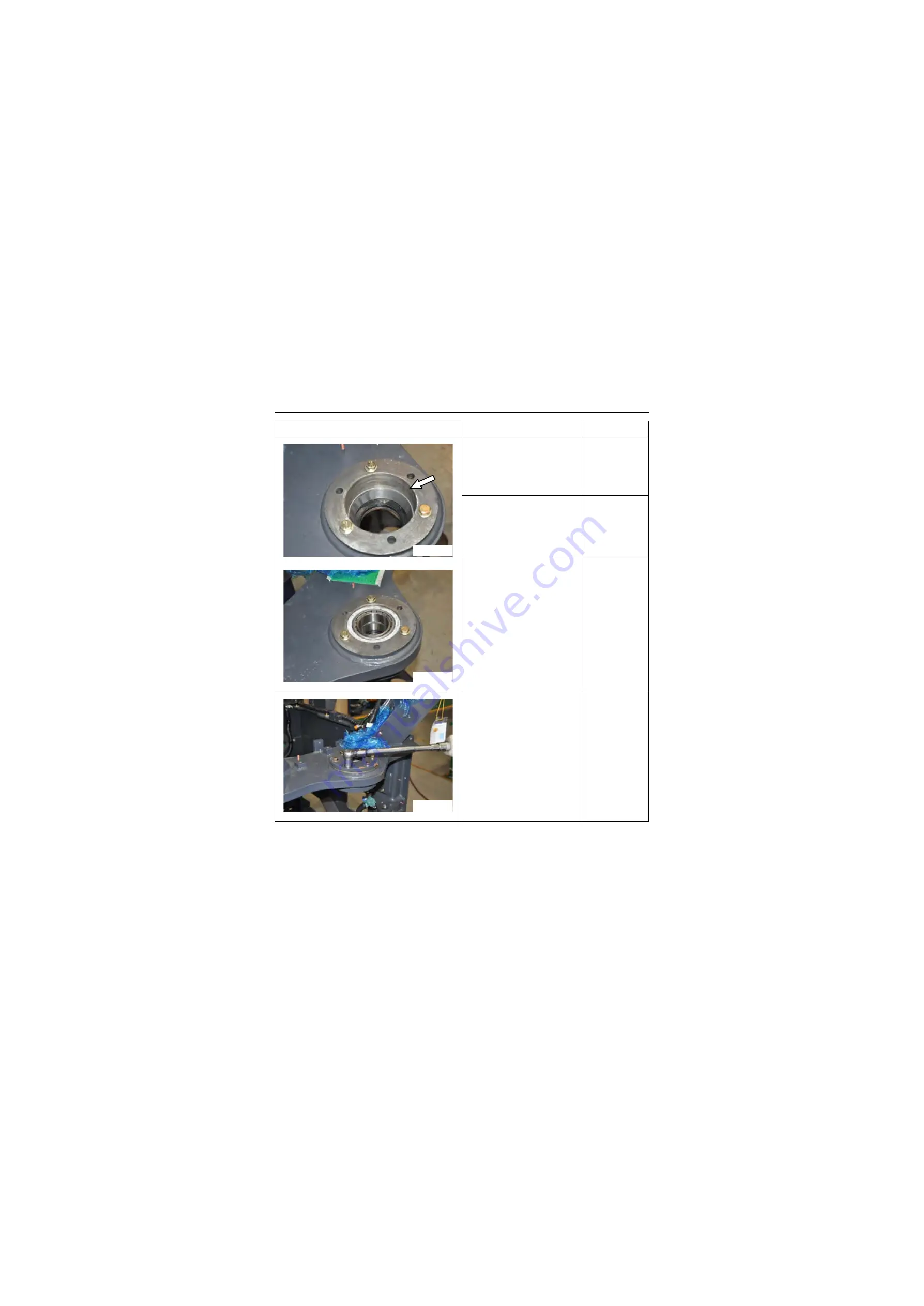

5. Install one frozen tapered

roller bearing cone cup into

lower hinge hole

Copper bar and

bearing knock-

ing tooling

6. Install two tapered roller

bearing cones into lower

hinge holes, and pay atten-

tion that two tapered roller

bearing cones are in oppo-

site directions.

Copper bar

7. Install another frozen taper

roller bearing cone cup into

lower hinge hole.

Copper bar and

bearing knock-

ing tooling

8. Select the shim with

appropriate thickness, install

the shim and upper and

lower covers, tighten

mounting bolts, and

tightening torque is:

120±10N.m/ 88.5±7.375

lbf·ft.

18# Wrench

Torque wrench

Figures

Operation instruction

Tools

P18S00020

P18S00021

P18S00022

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...