7-49

January 24, 2017

Removal and Installation

CLG835H

Removal and installation of work implement system

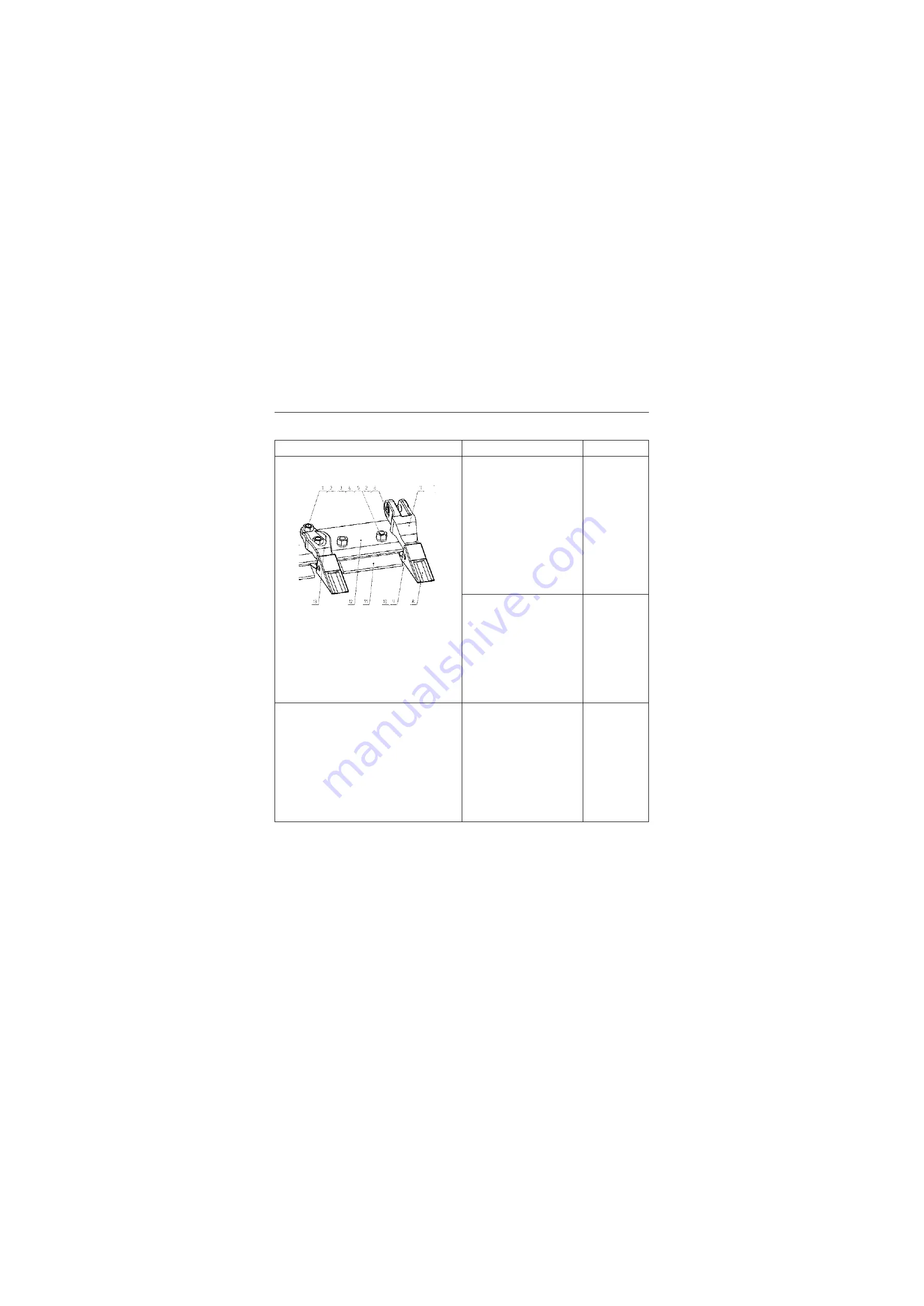

Replacement of bucket movable blade, movable tooth and tip

Figures

Operation instruction

Tools

1. Replace the tip:

1) Use hammer and pin

knocking tooling to remove

the pin (9) connecting tip

and tooth.

2) Take out the tip (8) and the

retainer (10).

3) Install new retainer (10) and

tip (8).

(4) Align the tip with tip mount-

ing hole, and install new pin

(9).

Hammer and pin

knocking tooling

2. Replace the middle tooth of

bucket:

1) Remove the nut (2) and

lock bolt (1) fixing tooth.

2) Take out the tooth (13).

3) Install new tooth (13) on

cutting edge (12).

4) Install new lock bolt (1) and

nut (2).

50# Socket

wrench

3. Replace the side tooth of

bucket:

1) Remove the nut (2) and

lock bolt (6) fixing side

tooth.

2) Take out the side tooth (7).

3) Install new side tooth (7) on

cutting edge (12).

4) Install new lock bolt (6) and

nut (2).

50# Socket

wrench

P18S00080

1. Lock bolt

2. Nut

3. Nut

4. Washer

5. Bolt

6. Lock bolt

7. Side gear body

8. Gear sleeve

9. Pin

10.Retainer

11.Movable Blade

12.Cutting edge

13.Gear body

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...