7-52

Removal and Installation

January 24, 2017

Option work implement and accessory system

CLG835H

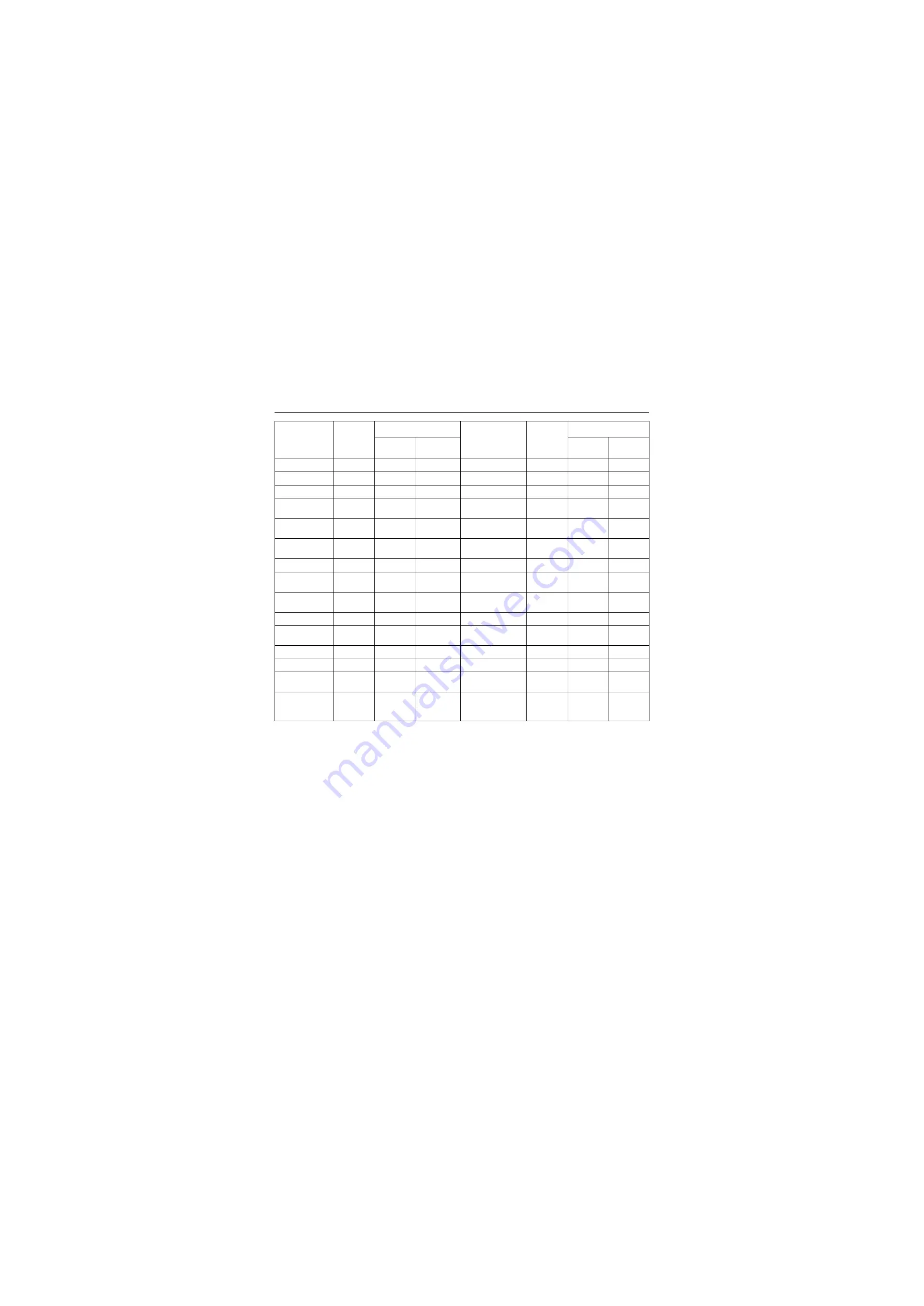

Magnet ore

2.5~3.5

30° ~35°

40° ~45°

Fine sand (dry)

1.4~1.65

30°

Hematite

2.0~2.8

30°~35°

40° ~45°

Fine sand (wet)

1.3~2.1

30°~35°

Limonite

1.2~2.1

30°~35°

40° ~45°

Moulding sand

0.8~1.3

30°

45°

Manganese ore

1.7~1.9

35°~45°

Limestone (large

block)

1.6~2.0

30°~35°

40°~45°

Magnesia

(agglomerate)

2.2~2.5

40°~42°

Limestone

(medium block)

1.2~1.5

30°~35°

40°~45°

Magnesia

powder

2.1~2.2

45°~50°

Quicklime

1.7~1.8

25°

45°~50°

Copper ore

1.7~2.1

35°~45°

Gravel

1.32~2.0

35°

45°

Copper

concentrate

1.3~1.8

40°

Dolomite (block)

1.2~2.0

35°

Plumbum

concentrate

1.9~2.4

40°

Dolomite fragment

1.8~1.9

35°

Zinc concentrate

1.3~1.7

40°

Gravel

1.5~1.9

30°

30°~45°

Plumbum-zinc

concentrate

1.3~2.4

40°

Clay (small block)

0.7~1.5

40°

50°

Sintered iron

1.7~2.0

45°-50°

Clay (wet)

1.7

27°~45°

Sinter fragment

1.4~1.6

35°

Concrete

0.9~1.7

35°

40°~45°

Sintered

plumbum

1.8~2.2

Slaked lime (pow-

der)

0.5

Sintered

plumbum and

zinc

1.6~2.0

Slaked lime (block)

2.0

Material

Bulk

density

/t•m

-3

Repose angle

Material

Bulk

density

/t•m

-3

Repose angle

Motion

Rest

Motion

Rest

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...