3-8

Basic Information

January 24, 2017

Maintenance and replacement of gearbox and drive axle oil

CLG835H

Maintenance and replacement of

gearbox and drive axle oil

The oil product added to the torque converter -

gearbox assembly must be consistent with oil list

TE-ML 03 recommended by ZF, the oil level shall

be checked once a week by the following

methods:

1) Park the machine on level ground;

2) Place the gear box gear in the neutral posi-

tion;

3) Torque converter - gearbox oil is at 80-

95°C\176°F~203°F;

4) The engine is idling 800rpm);

5) Observe the oil level gauge of gearbox and

it shall be in the "HOT" zone;

After the torque converter and gearbox assembly

co-work for the first 100h, the oil shall be

replaced every 1000h or at least once a year. Oil

can be replaced by the methods as below:

1) Unscrew the drain plug on the torque con-

verter - gearbox assembly to drain the oil.

2) After the Oil sump tank of the gear box com-

pletely gets empty, wipe clean the mating

surface on drain plug and gearbox housing

that contacting with O ring of the oil drain

plug. After the O-ring of the oil drain plug is

replaced, reassemble and tighten it.

3) Add the oil in accordance with the oil list TE-

ML 03 as recommended by ZF;

4) Check the oil level by the method as speci-

fied for transmission.

The fine oil filter is also replaced every time the

oil change is done for the gear box. The oil filter

may be installed by the following method:

1) Apply a small amount of the gear box oil on

the oil seal of oil filter;

2) The oil filter is screwed in until the oil seal of

oil filter contacts the filter head, tighten it 1/3

to 1/2 turn by hand.

The oil product added in the drive axle must be

in accordance with the oil list of 85W-90 heavy-

load wheel gear oil (GL-5) recommended by

LiuGong. The oil level of LiuGong axle may be

checked by the following methods:

The waste oil shall be collected in a container

during oil drainage, in order to avoid environ-

mental contamination;

The oil shall be fully cooled before oil drain-

age, in order to avoid personal injury due to

hot oil splashing onto the body.

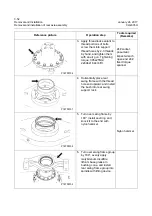

Figure 3-4 Gearbox drain plug

P18T00004

P18T00004

Figure 3-5 Wheel drain plug and oil level check

plug

P18T00005

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...