4-19

January 24, 2017

Structure Function Principle

CLG835H

Work hydraulic system

1. When there is no action in the work hydraulic

system, i.e. boom reversing valve and bucket

reversing valve in the control valve are in

neutral position, and variable plunger pump

is at minimum displacement position, the

variable pump hardly has oil to output (only

the minimum displacement required to keep

self-running), oil passages of the control

valve connected to both of big and small cav-

ities of the boom cylinder and bucket cylinder

are sealed, and boom and bucket are kept in

original position.

2. Operate the boom reversing valve controlled

by the pilot valve to lift, lower or float the

boom and manipulate the bucket tilting

reversing valve controlled by the pilot valve to

tilt the bucket forward or backward. There is

an automatic leveling device of bucket

installed on bucket hydraulic cylinder.

3. Big and small cavities double-acting safety

valves are installed in oil lines of the control

valve connected with big and small cavities of

the bucket cylinder to protect the big and

small cavities of the bucket cylinder from

overload and fill oil and play the role of stabi-

lizing system work and protecting the rele-

vant elements of the system.

B: Technical parameters of work system

Hydraulic oil tank

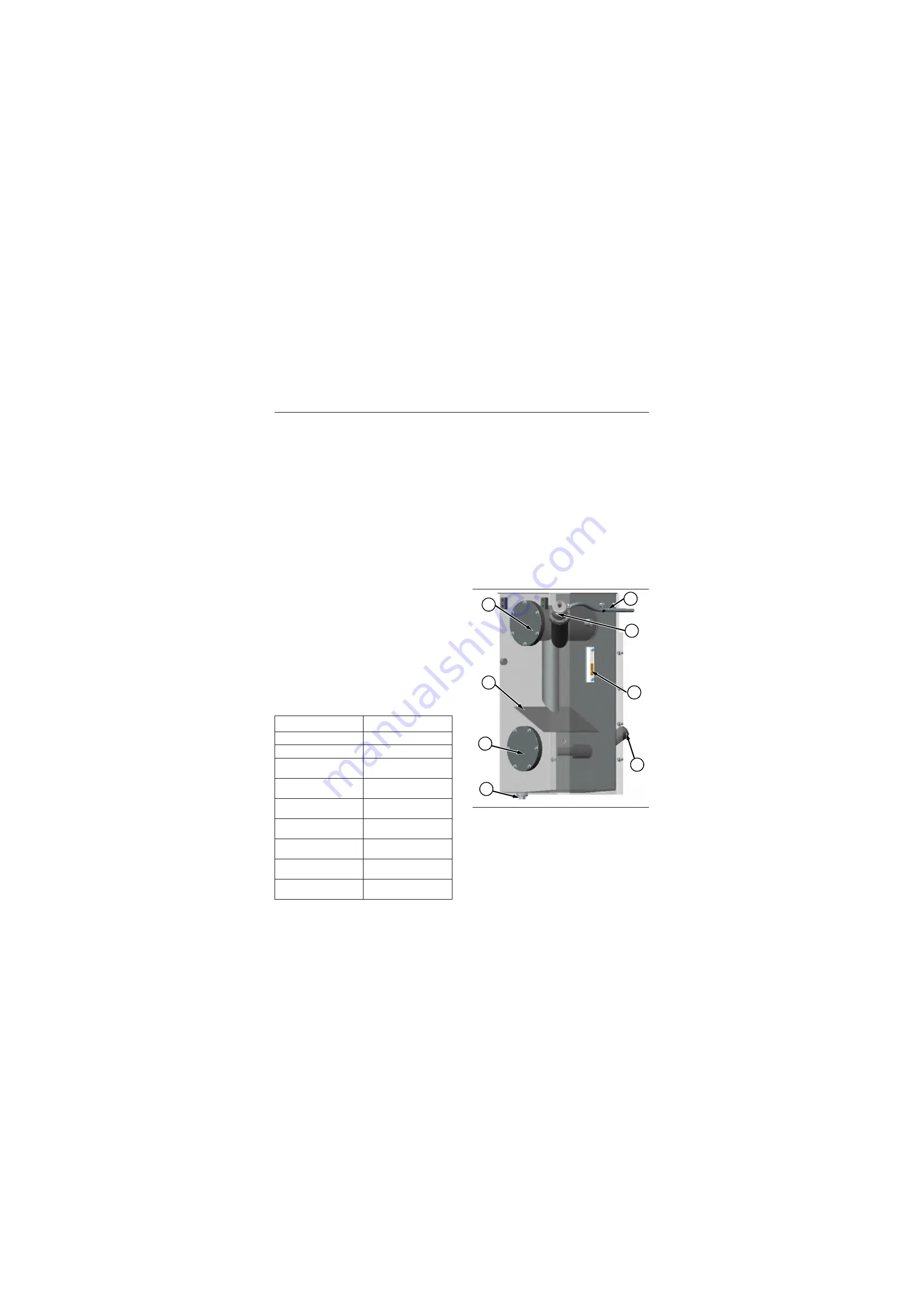

Installation position and functional structure

The hydraulic oil tank is side-sited type, which is

located on the rear frame in the middle of a

machine, the right side of a cab. The main

function is to store the hydraulic oil required for

work cycle of the hydraulic system and

precipitate the pollutant of oil in hydraulic tank,

separate the air from oil and cool the hydraulic

oil. A return oil filter has been set in the oil tank to

filter the pollutant in oil lines of the hydraulic

system so as to guarantee the cleanliness of

hydraulic oil. Structural diagram of hydraulic oil

tank is as follows:

Items

Parameters

System pressure

19±0.3Mpa\2755±43.5psi

System flow

210L/min@2200r/min

Pressure of overload

valve at A1 port

23±0.3MPa\3335±43.5psi

Pressure of overload

valve at B1 port

23±0.3MPa\3335±43.5psi

Pressure of overload

valve at A2 port

23±0.3MPa\3335±43.5psi

Pressure of overload

valve at B2 port

23±0.3MPa\3335±43.5psi

Pressure of overload

valve at A3 port

23±0.3MPa\3335±43.5psi

Pressure of overload

valve at B3 port

23±0.3MPa\3335±43.5psi

Pressure of main safety

valve

21±0.3MPa\3045±43.5psi

Structural diagram of hydraulic oil tank

1. Oil return chamber

and oil return filter

2. Baffle

3. Washing port

4. Oil drain hole

5. Ventilated oil conduit

6. Oil filler, oil filter element and

breather

7. Sight glass

8. Oil suction port

P18H00010

·

1

2

3

4

5

6

7

8

Summary of Contents for CLG835H

Page 2: ......

Page 4: ...Contents January 24 2017 CLG835H...

Page 6: ...1 2 General Information January 24 2017 CLG835H...

Page 38: ...1 34 Machine Inspection Table January 24 2017 CLG835H...

Page 156: ...3 2 Power Train System January 24 2017 CLG835H...

Page 214: ...3 2 Power Train System January 24 2017 CLG835H...

Page 272: ...3 60 Testing and adjustment January 24 2017 Power Train Test CLG835H...

Page 276: ...4 4 Hydraulic System January 24 2017 CLG835H...

Page 552: ...6 2 Driver s Cab System January 24 2017 CLG835H...

Page 608: ...7 2 Structure January 24 2017 CLG835H...

Page 662: ...8 4 Electrical System January 24 2017 CLG835H...

Page 677: ...8 19 January 24 2017 Structure Function Principle CLG835H Power System P18E00014...