– 22 –

Checking The Burner Velocity Pressure

PS-10 & PS-11 air switches are factory calibrated.

Do not adjust.

Check the velocity pressure by disconnecting both

pressure sensing tubes from one of the high air

fl

ow

switch. Connect one end of your manometer to each

sensing tube and start the fan. The permissible

pressure range should be marked on the switches.

If it’s close to the high or low trip points of the air

fl

ow

switches, you could have a problem: High pressure

switch open means too much velocity; low pressure

switch open means not enough velocity.

Jumper the switch from which you’ve disconnected the

sensing tubes and get the burner running in high

fi

re.

Your differential pressure should have dropped. If it is

near the low switch trip point you need more air.

Some adjustments can be made by repositioning the

burner pro

fi

le plates. If the high switch is open, you

can open the pro

fi

le plates. If the low switch is open

you can close the pro

fi

le plates. Remember to keep

the distance between the burner and pro

fi

le plates

the same opening on both the top and bottom of the

burner when making these adjustments.

Depending on the motor amps you may want to

change the speed of the fan if the unit has adjustable

sheaves.

Don’t forget to remove the jumper and reconnect the

sensing tubes to the switch.

Call factory with any questions.

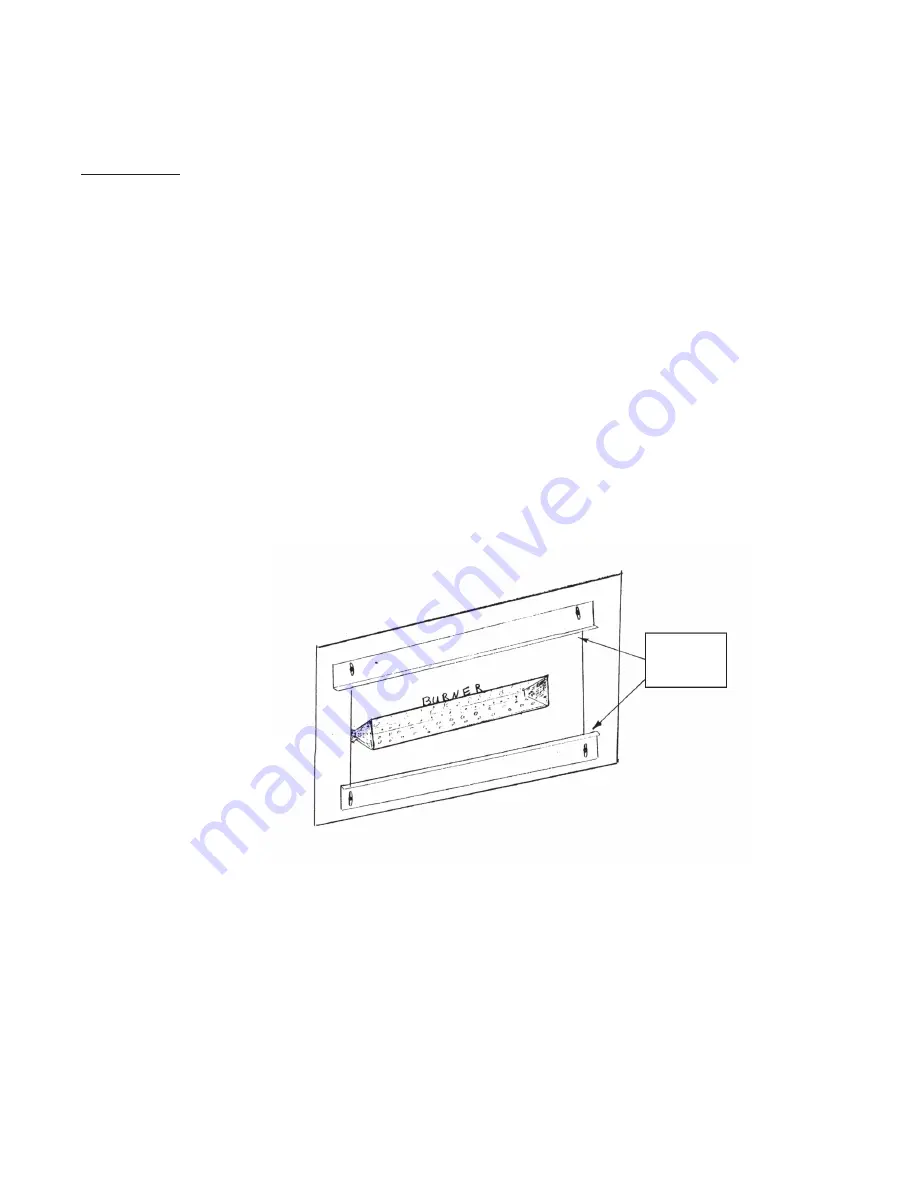

Pro

fi

le

Plates

TROUBLESHOOTING GUIDE