11 (15)

EN.33.C.94.1702

Assembly instructions | LK Electric Boiler 11-n

Steady illumination Normal operation

One long + one

short flash

Delay in connection after a power outage limits output adjustment.

One long + two

short flashes

Loading relay, room thermostat or some other external control device limits output adjustment.

One long + three

short flashes

A. Overheating (maximum safe) temperature

Connected output becomes disconnected immediately when the temperature exceeds set point value by

more than 5 °C. Reconnection takes place when temperature falls below overheating (maximum safe)

temperature.

B. Malfunction at boiler temperature sensor

Output is not switched on despite temperature being below set point value. Replace sensor. Acknow-

ledge alarm by keeping boiler switched off for 10 seconds, turn main switch to position 0.

One long + four

short flashes

Remote control activated.

Rapid flashes

By-passing of the connection delay: SNABB (Quick) button, item 13 in wiring diagram, keep button

pressed down until status indicator is illuminated steadily.

Loss of pressure

No voltage or selector in position:

UTK panel

15

14

13

11

12

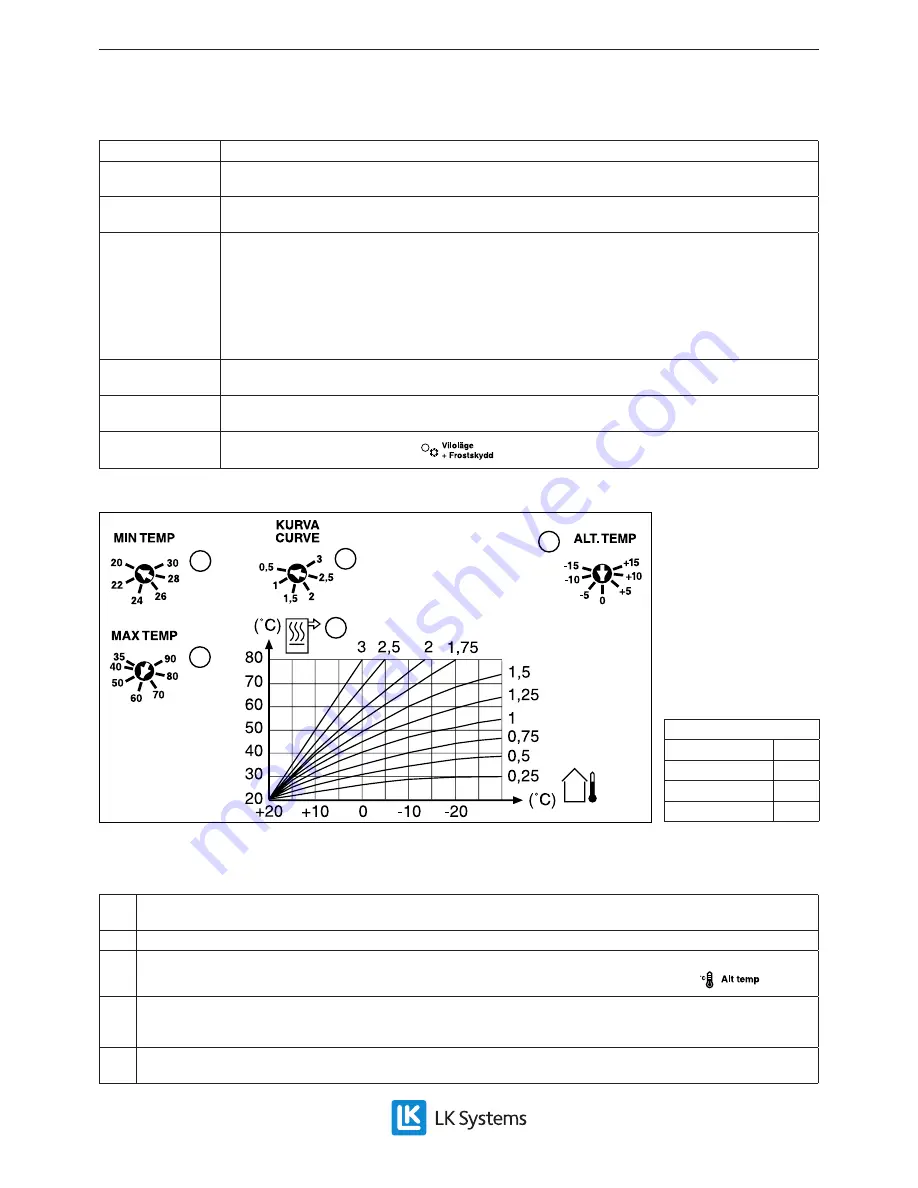

The panel is viewable once the boiler’s top support has been taken off and the automation cabinet’s control

panel has been folded out.

11.

Temperature diagram: This shows the dependence of the temperature of the flow water on the selected graph and the

outside temperature.

12. Maximum temperature: Highest allowed temperature, 60 °C, (not adjustable).

13. Alternative temperature: The temperature of the outgoing water can be increased/decreased ±15 °C in relation to the

normal temperature. Adjustments are implemented by using the selector switch, see item 5 above.

,

14. Water temperature flow rates used as the output values available on the graph are used in the floor heating calcula-

tions. If these values are not available, use graph 1 for under floor heating systems laid over a timber sub-floors. If the

loops of tubing are embedded in concrete, use a lower graph, e.g. 0.75.

15. Minimum temperature: Lowest allowed temperature of flow water. If there is no particular requirement, do the installa-

tion for a temperature of 20 °C.

Supply settings:

Min. temp.

20 ºC

Graph

1

Alternative temp. -5 ºC

Max temp.

60 ºC