21

Instruction Manual

SECTION 4 - MAINTENANCE

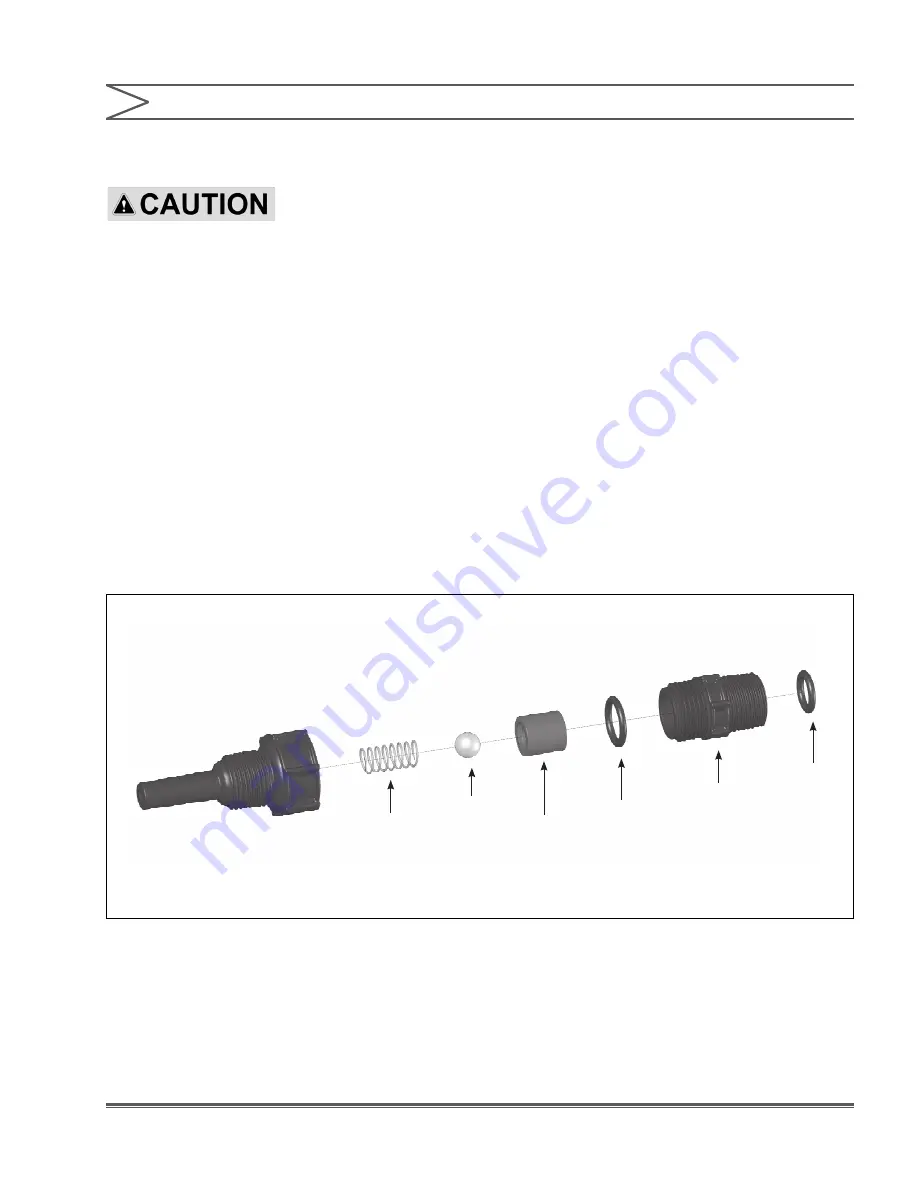

4.5 INJECTION CHECK VALVE PARTS

REPLACEMENT

DEPRESSURIZE AND DRAIN

PIPELINE (OR ISOLATE

INJECTION CHECK VALVE POINT USING VALVES) SO THAT

INJECTION CHECK VALVE CAN SAFELY BE DISASSEMBLED.

ALWAYS WEAR PROTECTIVE CLOTHING, FACE SHIELD,

SAFETY GLASSES AND GLOVES WHEN WORKING NEAR OR

PERFORMING ANY MAINTENANCE OR REPLACEMENT ON

YOUR PUMP. SEE SDS INFORMATION FROM SOLUTION

SUPPLIER FOR ADDITIONAL PRECAUTIONS.

Refer to the LMI

®

Metering Pump Price List for

the proper Spare Parts Kit or RPM PRO PAC™

kit number or contact your local LMI

®

stocking

distributor.

1. Isolate Injection Check Valve and depressurize

pipe or drain pipeline.

2. Carefully depressurize and disconnect the

discharge line (

see Section 4.1 or 4.2 in this

manual

).

Spare part replacement kits include specific

instructions for valve replacement. Please follow

the instructions included with the replacement kit.

3. Carefully disconnect the tubing leading to the

Injection Check Valve, then remove the Injection

Check Valve Fitting. Remove and replace the

worn spring, seat, ball and O-ring.

NOTE:

Before disassembling the check valve, note the

orientation of the parts.

4. Install a new spring, seat, ball and O-ring.

Ensure that the parts are oriented correctly.

Spring

Ball

Seat

O-Ring

O-Ring

Injection Check

Valve Fitting

Figure 18. Injection Check Valve Parts Replacement

Summary of Contents for ROYTRONIC A Series

Page 35: ......