CHAPTER 7: OPERATION

7-3

ECOLOAD S2

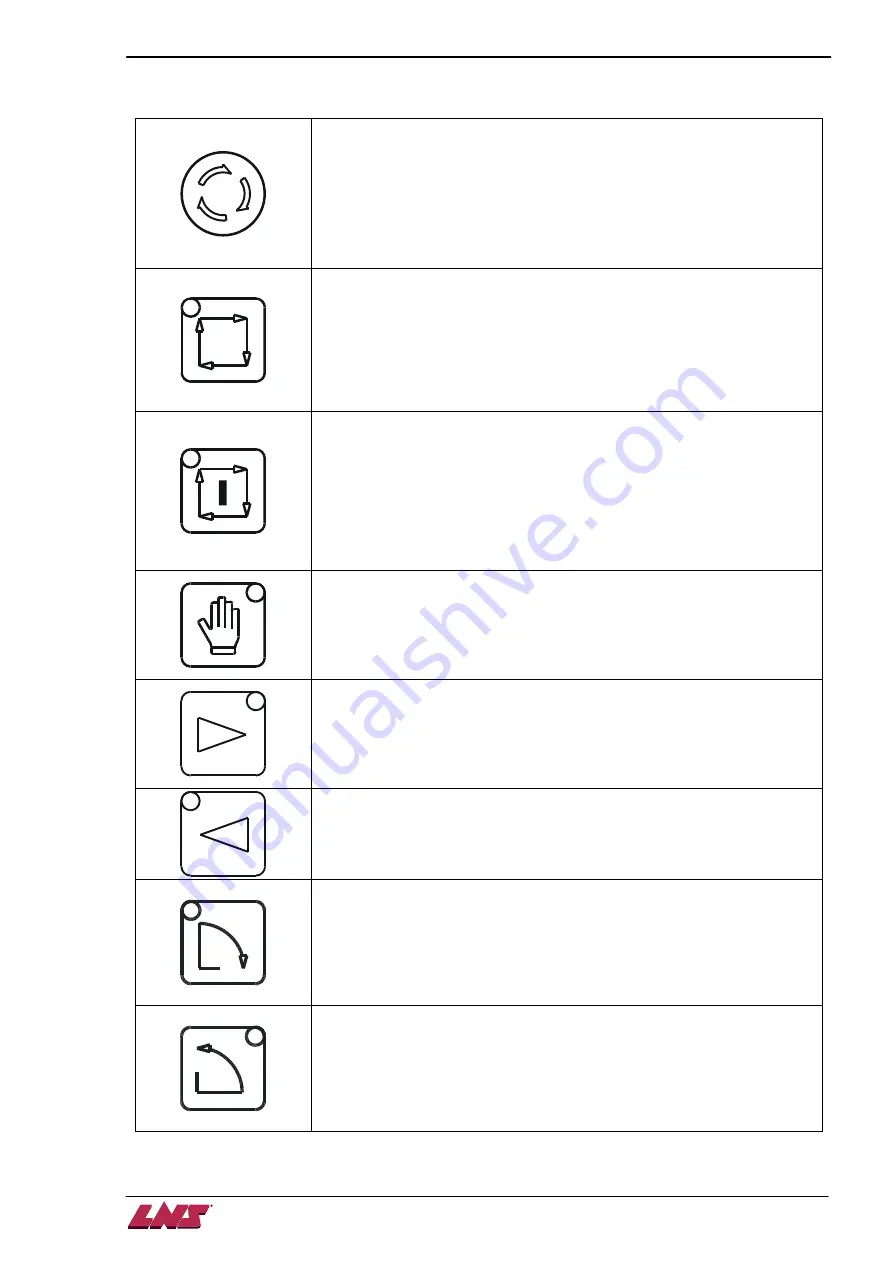

1.2. Functions keys

Emergency stop

When a dangerous situation arises, pressing the emergency stop button

immediately interrupts the bar feeder. The bar feeder will send alarm

signal to the lathe and interrupt the lathe if interface is wired accordingly.

Error message e01 will be shown on the HMI display.

To cancel the alarm, release the button by rotating it clockwise and

pressing the

MANUAL

mode key.

Auto ready

To switch the bar feeder to

AUTOMATIC ready

mode.

In

AUTOMATIC ready

mode, the key LED is ON. The bar feeder is

available to be switched to

AUTOMATIC

mode.

To switch to

AUTOMATIC ready

mode, following conditions must be

fulfilled:

The V channel is at 15° position for long pusher feeding.

Auto start

To switch the bar feeder to

AUTOMATIC

mode. In

AUTOMATIC

mode,

the key LED is ON. The bar feeder is running the automatic sequence

controlled by the lathe.

To switch to

AUTOMATIC

mode, the following conditions must be

fulfilled :

The V channel is at 15° position for long pusher feeding and bar

feeder is in AUTOMATIC ready mode.

Manual

Switch the bar feeder to

MANUAL

mode. When the bar feeder is on

MANUAL

mode, the key LED is ON and the user could operate the bar

by function keys.

Reset the bar feeder from an emergency stop.

Rightward

Move pusher rightward.

Only available when the bar feeder is in

MANUAL

mode

Indicate the position of pusher. When the pusher passes FIRST FEED

position set up on P08, the LED will be ON.

Leftward

Move pusher leftward (to home position). Only available when the bar

feeder is in

MANUAL

mode.

When the pusher arrives at home position, the LED will be ON.

15° Position

Only available when bar feeder is in

MANUAL

mode and the pusher is

at home position.

Tilt V channel to 15° position for long pusher feeding. The channel and

loading fingers will be let down. When the channel arrives at 15° position,

the LED will be ON.

0° Position

Only available when bar feeder is in

MANUAL

mode and the pusher is

at home position.

Tilt V channel to 0° position for short pusher feeding. The channel and

loading fingers will be lifted up. When the channel arrives at 0° position,

the LED will be ON.

Summary of Contents for Eco Load S2

Page 1: ...LNS SA 2534 Orvin Switzerland www LNS group com Instruction manual ENG 9 ECO 01 ...

Page 2: ......

Page 5: ...CHAPTER 1 BASIC NOTIONS 1 1 ECOLOAD S2 CHAPTER 1 BASIC NOTIONS ...

Page 12: ...1 8 CHAPTER 1 BASIC NOTIONS ECOLOAD S2 ...

Page 13: ...CHAPTER 2 TECHNICAL DATA 2 1 ECOLOAD S2 CHAPTER 2 TECHNICAL DATA ...

Page 17: ...CHAPTER 2 TECHNICAL DATA 2 5 ECOLOAD S2 2 3 Z axis retraction system ˋˆˊ ˊˋˊ ˌˊ ˉ ˁˈ ʳ ˆˇ ˈ ...

Page 19: ...CHAPTER 3 SETTING INTO OPERATION 3 1 ECOLOAD S2 CHAPTER 3 SETTING INTO OPERATION ...

Page 36: ...3 18 CHAPTER 3 SETTING INTO OPERATION ECOLOAD S2 ...

Page 37: ...CHAPTER 4 ELECTRICS 4 1 ECOLOAD S2 CHAPTER 4 ELECTRICS ...

Page 43: ...CHAPTER 4 ELECTRICS 4 7 ECOLOAD S2 4 2 Circuit diagram ...

Page 45: ...CHAPTER 4 ELECTRICS 4 9 ECOLOAD S2 5 2 PLC I O DIAGRAMS ...

Page 54: ...4 18 CHAPTER 4 ELECTRICS ECOLOAD S2 ...

Page 55: ...CHAPTER 5 PNEUMATICS 5 1 ECOLOAD S2 CHAPTER 5 PNEUMATICS ...

Page 57: ...CHAPTER 5 PNEUMATICS 5 3 ECOLOAD S2 2 PNEUMATIC CIRCUIT DIAGRAM ...

Page 62: ...5 8 CHAPTER 5 PNEUMATICS ECOLOAD S2 ...

Page 63: ...CHAPTER 6 GENERAL DESCRIPTION 6 1 ECOLOAD S2 CHAPTER 6 GENERAL DESCRIPTION ...

Page 77: ...CHAPTER 7 OPERATION 7 1 ECOLOAD S2 CHAPTER 7 OPERATION ...

Page 98: ...7 22 CHAPTER 7 OPERATION ECOLOAD S2 ...

Page 99: ...CHAPTER 8 TROUBLESHOOTING GUIDE 8 1 ECOLOAD S2 CHAPTER 8 TROUBLESHOOTING GUIDE ...

Page 109: ...CHAPTER 9 APPENDICES 9 1 ECOLOAD S2 CHAPTER 9 APPENDICES ...