Chapter 1: Alarms

HYDROBAR EXPRESS 220

1-49

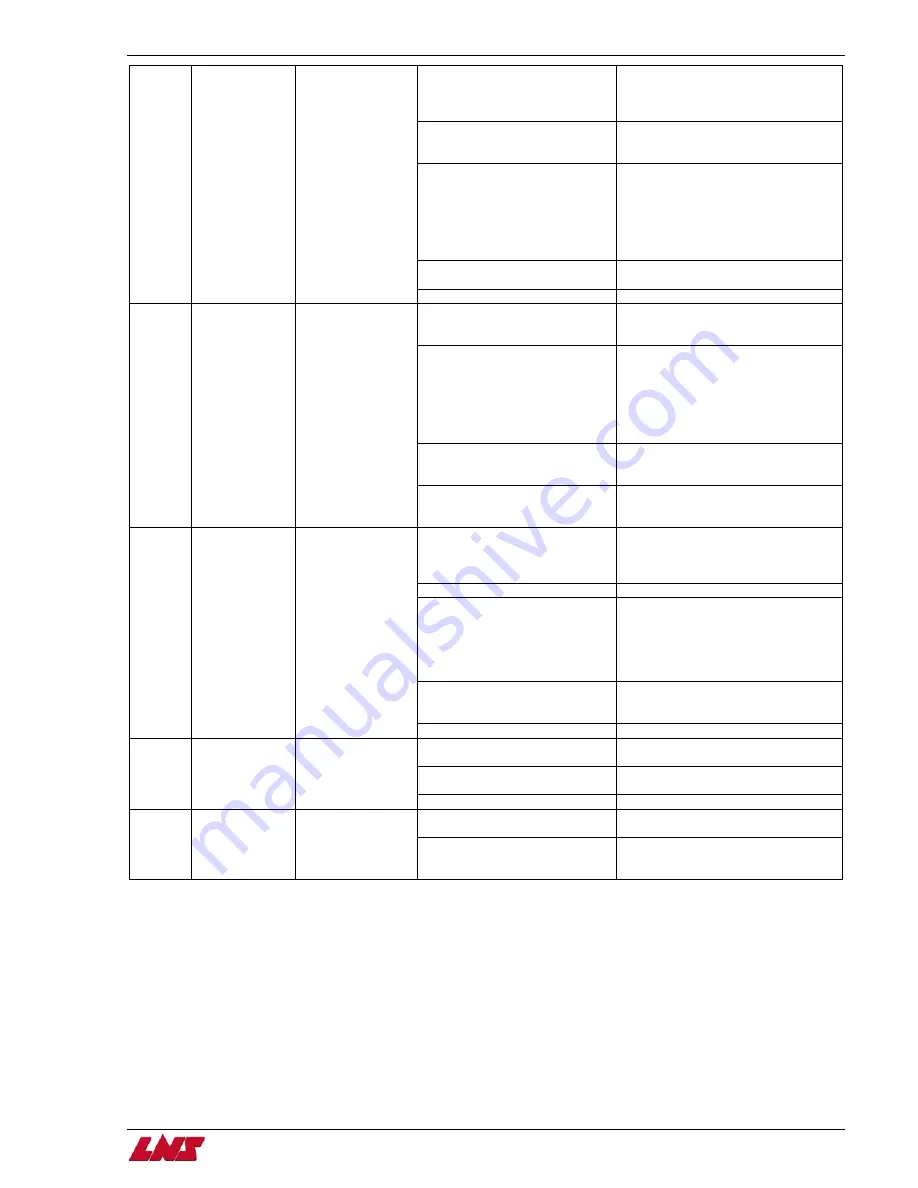

1. Input command pulse

frequency exceeded the

permissible instantaneous speed

frequency.

Set command pulses correctly.

2. Small acceleration/deceleration

time constant caused overshoot to

be large.

Increase acceleration/deceleration time

constant.

3. Servo system is instable to

cause overshoot.

1. Re-set servo gain to proper value.

2. If servo gain cannot be set to proper

value:

1) Reduce load inertia moment ratio; or

2) Reexamine

acceleration/deceleration time

constant.

4. Electronic gear ratio is large

(parameters No. 4, 5)

Set correctly.

AL.31 Overspeed

Speed

has

exceeded the

instantaneous

permissible speed.

5. Encoder faulty.

Change the servo motor.

1. Short occurred in servo

amplifier output phases U, V and

W.

Correct the wiring.

2. Transistor (IPM) of the servo

amplifier faulty.

Checking method

Alarm (AL.32) occurs if power is

switched on after U, V and W are

disconnected.

Change the servo amplifier.

3. Ground fault occurred in servo

amplifier output phases U, V and

W.

Correct the wiring.

AL.32

Overcurrent

Current that flew is

higher than the

permissible current

of the servo

amplifier.

4. External noise caused the

overcurrent detection circuit to

misoperate.

Take noise suppression measures.

1. Lead of built-in regenerative

brake resistor or regenerative

brake option is open or

disconnected.

1. Change lead.

2. Connect correctly.

2. Regenerative transistor faulty.

Change servo amplifier

3. Wire breakage of built-in

regenerative brake resistor or

regenerative brake option

1. For wire breakage of built-in

regenerative brake resistor, change

servo amplifier.

2. For wire breakage of regenerative

brake option, change regenerative

brake option.

4. Capacity of built-in regenerative

brake resistor or regenerative

brake option is insufficient.

Add regenerative brake option or

increase capacity.

AL.33 Overvoltage

Converter

bus

voltage exceeded

400V.

5. Power supply voltage high.

Review the power supply.

1. Pulse frequency of the manual

pulse generator is too high.

Change the pulse frequency to a

proper value.

2. Noise entered the pulses of the

manual pulse generator.

Take action against noise.

AL.35 Command

pulse

frequency error

Input pulse

frequency of the

command pulse is

too high.

3. Manual pulse generator failure

Change the manual pulse generator.

1. Servo amplifier fault caused the

parameter setting to be rewritten.

Change the servo amplifier.

AL.37 Parameter

error Parameter

setting

is wrong.

2. Regenerative brake option not

used with servo amplifier was

selected in parameter No.0.

Set parameter No.0 correctly.

Summary of Contents for Hydrobar Express 220

Page 61: ......

Page 143: ......

Page 147: ......

Page 156: ...Chapter 6 Spare Parts 6 9 HYDROBAR EXPRESS 220 Servo Motor Assembly ...

Page 161: ...6 14 Chapter 6 Spare Parts HYDROBAR EXPRESS 220 Hydraulic Pump Assembly ...

Page 163: ...6 16 Chapter 6 Spare Parts HYDROBAR EXPRESS 220 Diameter Adjustment Motor Assembly ...

Page 164: ...Chapter 6 Spare Parts 6 17 HYDROBAR EXPRESS 220 Air Regulator and Cable Passage Plate ...