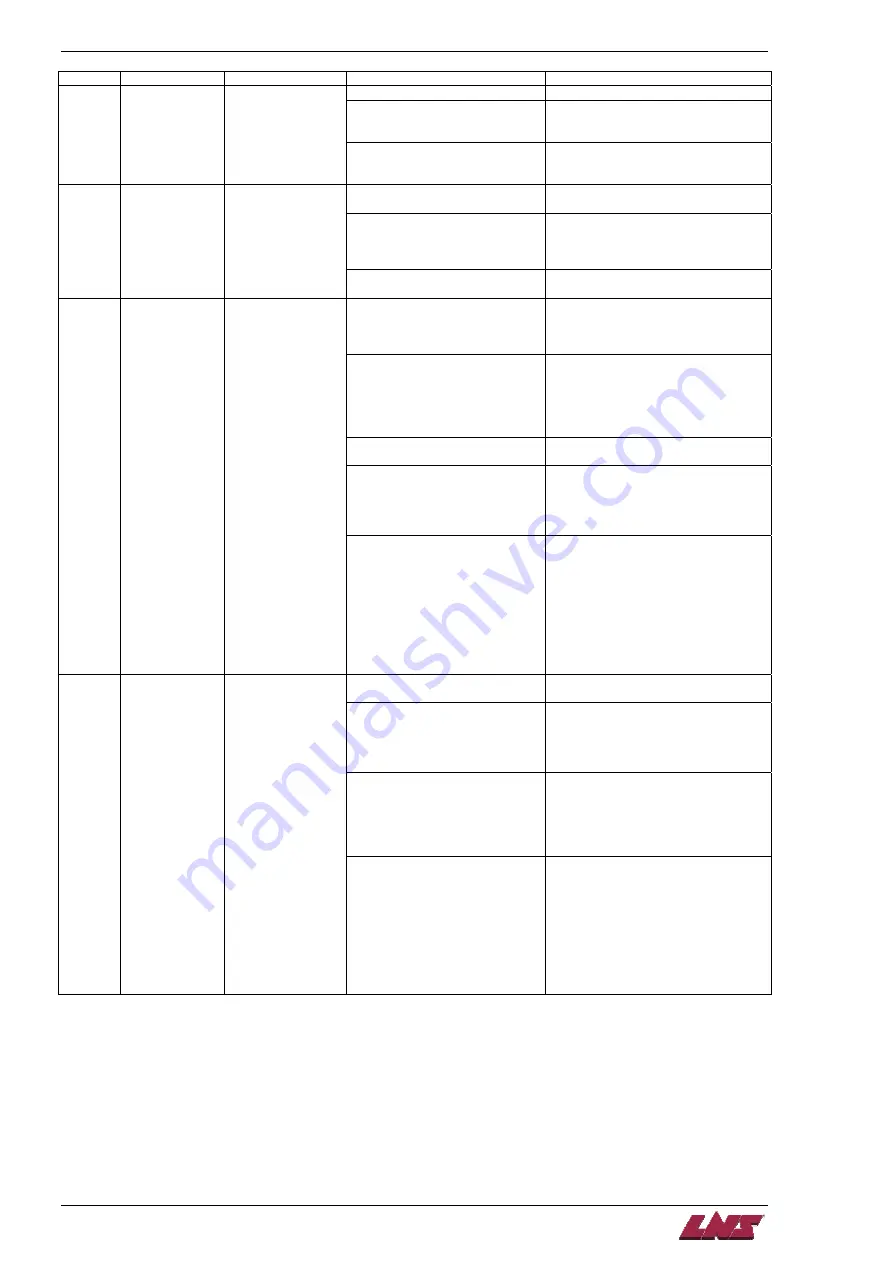

C H A P T E R 1 : A L A R M S

1 - 3 2

Display Name

Definition

Cause

Action

1. Servo amplifier faulty.

Change the servo amplifier.

2. The power supply was turned

on and off continuously by

overloaded status.

The drive method is reviewed.

AL.45 Main

circuit

device overheat

Main circuit device

overheat

3. Air cooling fan of servo

amplifier stops.

1. Exchange the cooling fan or the

servo amplifier.

2. Reduce ambient temperature.

1. Ambient temperature of servo

motor is over 40

°

C.

Review environment so that ambient

temperature is 0 to 40

°

C.

2. Servo motor is overloaded.

1. Reduce load.

2. Review operation pattern.

3. Use servo motor that provides larger

output.

AL.46 Servo

motor

overheat

Servo motor

temperature rise

actuated the

thermal protector.

3. Thermal protector in encoder is

faulty.

Change servo motor.

1. Servo amplifier is used in

excess of its continuous output

current.

1. Reduce load.

2. Review operation pattern.

3. Use servo motor that provides larger

output.

2. Servo system is instable and

hunting.

1. Repeat acceleration/ deceleration to

execute auto tuning.

2. Change auto tuning response

setting.

3. Set auto tuning to OFF and make

gain adjustment manually.

3. Machine struck something.

1. Review operation pattern.

2. Install limit switches.

4. Wrong connection of servo

motor. Servo amplifier's output

terminals U, V, W do not match

servo motor's input terminals U, V,

W.

Connect correctly.

AL.50

Overload 1

Load exceeded

overload protection

characteristic of

servo amplifier.

Load ratio 300%:

2.5s or more

Load ratio 200%:

100s or more

5. Encoder faulty.

Checking method

When the servo motor shaft is

rotated with the servo off, the

cumulative feedback pulses do

not vary in proportion to the rotary

angle of the shaft but the

indication skips or returns

midway.

Change the servo motor.

1. Machine struck something.

1. Review operation pattern.

2. Install limit switches.

2. Wrong connection of servo

motor. Servo amplifier's output

terminals U, V, W do not match

servo motor's input terminals U, V,

W.

Connect correctly.

3. Servo system is instable and

hunting.

1. Repeat acceleration/deceleration to

execute auto tuning.

2. Change auto tuning response

setting.

3. Set auto tuning to OFF and make

gain adjustment manually.

AL.51

Overload 2

Machine collision or

the like caused

max. output current

to flow successively

for several

seconds.

Servo motor

locked: 1s or more

4. Encoder faulty.

Checking method

When the servo motor shaft is

rotated with the servo off, the

cumulative feedback pulses do

not vary in proportion to the rotary

angle of the shaft but the

indication skips or returns

midway.

Change the servo motor.

QUICK LOAD SERVO 65/80

Summary of Contents for Quick Load Servo 65

Page 1: ...Troubleshooting manual ENG 9 020 01 ANG ...

Page 43: ......

Page 61: ......

Page 67: ......

Page 96: ...CHAPTER 6 SPARE PARTS QUICK LOAD SERVO 65 80 6 27 020 005 413 QLS 65 80 Locking block ...

Page 99: ...CHAPTER 6 SPARE PARTS 6 30 020 005 703 QLS 65 80 Sub assembly drive QUICK LOAD SERVO 65 80 ...

Page 101: ...CHAPTER 6 SPARE PARTS 6 32 020 005 723 QLS 65 80 Sub assembly cogwheel QUICK LOAD SERVO 65 80 ...

Page 115: ...CHAPTER 6 SPARE PARTS 6 46 020 011 013 12 QLS 65 Assembly pusher ø12 QUICK LOAD SERVO 65 80 ...

Page 116: ...CHAPTER 6 SPARE PARTS QUICK LOAD SERVO 65 80 6 47 020 011 013 20 QLS 65 Assembly pusher ø20 ...

Page 117: ...CHAPTER 6 SPARE PARTS 6 48 020 011 023 6 QLS 80 Assembly pusher ø1 4 QUICK LOAD SERVO 65 80 ...

Page 118: ...CHAPTER 6 SPARE PARTS QUICK LOAD SERVO 65 80 6 49 020 011 023 12 QLS 80 Assembly pusher ø12 ...

Page 119: ...CHAPTER 6 SPARE PARTS 6 50 020 011 023 20 QLS 80 Assembly pusher ø20 QUICK LOAD SERVO 65 80 ...