12

START UP MANUAL

QUICK LOAD SERVO S2

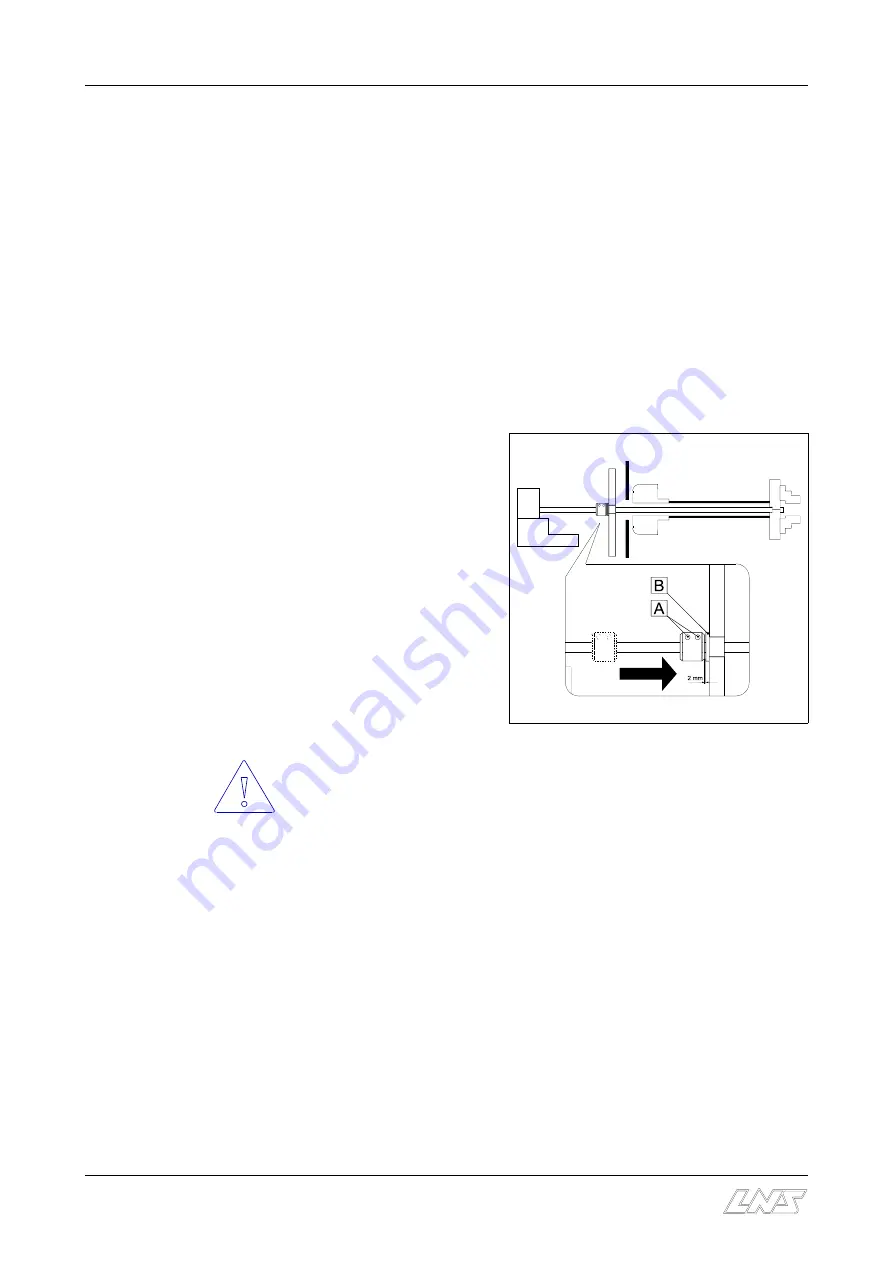

4.1.1 Mechanical stop

The feeding pusher of the Quick Load Servo bar feed system has a set length, which was

determined so that it can function with all types of lathes.

To make sure that they never collide with the clamping device (end of bar improperly

adjusted, or in manual mode, for example), the feeding pusher of the Quick Load Servo

comes with a mechanical safety stop.

When the mechanical stop (stop sleeve) comes into contact with the guide bushing, the

feeding pusher is immediately stopped.

Procedure :

•

Bring the loading channel into

work position (down position).

•

Open the main access cover.

•

Undo the set screws (A) of the

stop sleeve.

•

Close the main access cover.

•

Move the feeding pusher forward

to the end of the bar position (see

Chapter 7, Handling).

•

Slide the mechanical stop against

the guide bushing (B), and then

move it back 2 mm (.08").

•

Tighten the set screws.

•

Close the main access cover.

This setting must be done on all feeding pushers when the bar feed system is

being installed, and should be modified (not necessarily) only when the

clamping device is replaced (collet or chuck). In this case, the end of the bar

position should also be adjusted.

Summary of Contents for QUICK LOAD SERVO S2

Page 1: ...ENG MADE IN USA ...