Summary of Contents for QUICK LOAD SERVO S3 T BARFEED

Page 2: ...GENERAL SERVICE MANUAL QL Servo S3 T ...

Page 6: ...GENERAL SERVICE MANUAL QL Servo S3 T ...

Page 42: ...MECHANICAL EQUIPMENT SERVICE MANUAL QL Servo S3 T ...

Page 46: ...PNEUMATIC EQUIPMENT SERVICE MANUAL QL Servo S3 T ...

Page 64: ...ELECTRICAL EQUIPMENT SERVICE MANUAL QL Servo S3 T ...

Page 96: ...TECHNICAL CHARACTERISTICS SERVICE MANUAL QL Servo S3 T ...

Page 98: ...DISPOSAL SERVICE MANUAL QL Servo S3 T ...

Page 103: ...TROUBLESHOOTING SERVICE MANUAL QL Servo S3 T SEQUENCE DIAGRAM ...

Page 104: ...TROUBLESHOOTING SERVICE MANUAL QL Servo S3 T SEQUENCE LISTING ...

Page 105: ...TROUBLESHOOTING SERVICE MANUAL QL Servo S3 T ...

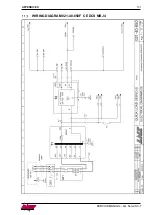

Page 122: ...APPENDICES 121 SERVICE MANUAL QL Servo S3 T WIRING DIAGRAM 021 40 620F CE MRJ 4 ...

Page 123: ...122 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 124: ...APPENDICES 123 SERVICE MANUAL QL Servo S3 T ...

Page 125: ...124 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 126: ...APPENDICES 125 SERVICE MANUAL QL Servo S3 T ...

Page 127: ...126 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 128: ...APPENDICES 127 SERVICE MANUAL QL Servo S3 T ...

Page 129: ...128 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 130: ...APPENDICES 129 SERVICE MANUAL QL Servo S3 T ...

Page 131: ...130 APPENDICES SERVICE MANUAL QL Servo S3 T ...

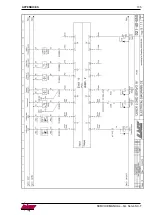

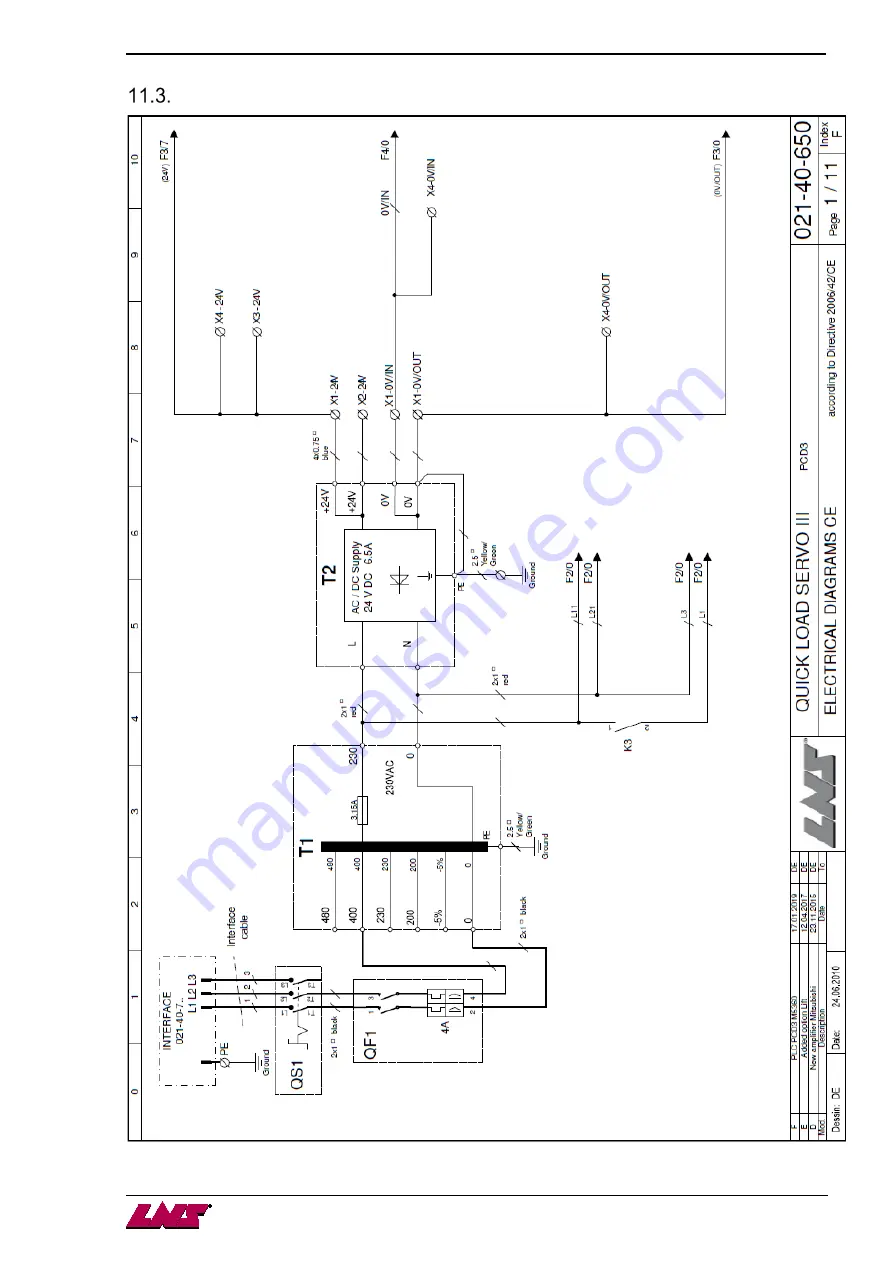

Page 132: ...APPENDICES 131 SERVICE MANUAL QL Servo S3 T WIRING DIAGRAM 021 40 650F CE DCS MRJ4 ...

Page 133: ...132 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 134: ...APPENDICES 133 SERVICE MANUAL QL Servo S3 T ...

Page 135: ...134 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 136: ...APPENDICES 135 SERVICE MANUAL QL Servo S3 T ...

Page 137: ...136 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 138: ...APPENDICES 137 SERVICE MANUAL QL Servo S3 T ...

Page 139: ...138 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 140: ...APPENDICES 139 SERVICE MANUAL QL Servo S3 T ...

Page 141: ...140 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 142: ...APPENDICES 141 SERVICE MANUAL QL Servo S3 T ...

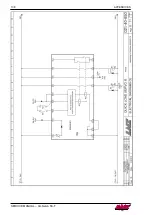

Page 143: ...142 APPENDICES SERVICE MANUAL QL Servo S3 T WIRING DIAGRAM 021 40 622C CE MRJ4 QLSIII MI ...

Page 144: ...APPENDICES 143 SERVICE MANUAL QL Servo S3 T ...

Page 145: ...144 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 146: ...APPENDICES 145 SERVICE MANUAL QL Servo S3 T ...

Page 147: ...146 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 148: ...APPENDICES 147 SERVICE MANUAL QL Servo S3 T ...

Page 149: ...148 APPENDICES SERVICE MANUAL QL Servo S3 T ...

Page 150: ...APPENDICES 149 SERVICE MANUAL QL Servo S3 T ...

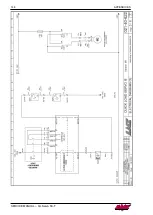

Page 151: ...150 APPENDICES SERVICE MANUAL QL Servo S3 T PNEUMATIC DIAGRAM ...