14

◆

To carry out the installation, connection, commissioning and

maintenance of SLA-3 device by qulified person

◆

This warranty does not cover damage or liability for misuse, abuse,

or the improper application or installation

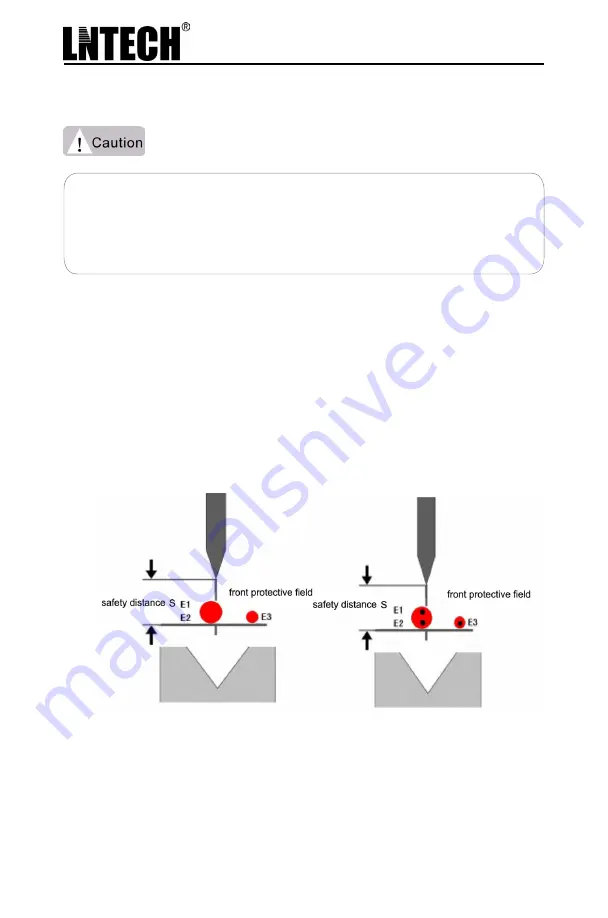

4.1 Safety Distance

The safety distance is the vertical line distance (S) from upper tool tip

to the bottom beam(E2), which is the min. distance allowed between

protection device and the dangerous area

The mounting position must be in line with the safety distance

requirements,otherwise may lead to serious injury

4 Installation

(

mm

)

Emitter Receiver

Summary of Contents for SLA-3

Page 2: ......

Page 27: ...23 5 2 SLA 3 Wiring with safety relay Fig 5 1 SLA 3 Wiring With Safety Relay...

Page 32: ...28 Fig 6 2 Test Procedure Diagram upper mould STOP...

Page 35: ......