Installation & Operation Manual

12

1

Determine unit location

Exhaust fans

Any fan or equipment which exhausts air from the boiler room

may deplete the combustion air supply and/or cause a down

draft in the venting system. Spillage of flue products from the

venting system into an occupied living space can cause a very

hazardous condition that must be immediately corrected. If a

fan is used to supply combustion air to the boiler room, the

installer must make sure that it does not cause drafts which

could lead to nuisance operational problems with the boiler.

Vertical DirectAire™, Horizontal DirectAire™, and Direct Vent

venting systems have specific requirements for combustion air

ducts from the outside which are directly connected to the unit.

See the requirements for combustion air duct in the venting

section.

Combustion air filter

This unit has a standard air filter located at the combustion air

inlet. This filter helps ensure clean air is used for the combustion

process. Check this filter every month and replace when it

becomes dirty. The filter size on Models 402 - 752 is 12" x 12"

x 1" (30.5cm x 30.5cm x 2.5cm) and 16" x 16" x 1" (40.6cm x

40.6cm x 2.5 cm) on Models 992 - 2072. You can find these

commercially available filters at any home center or HVAC

supply store.

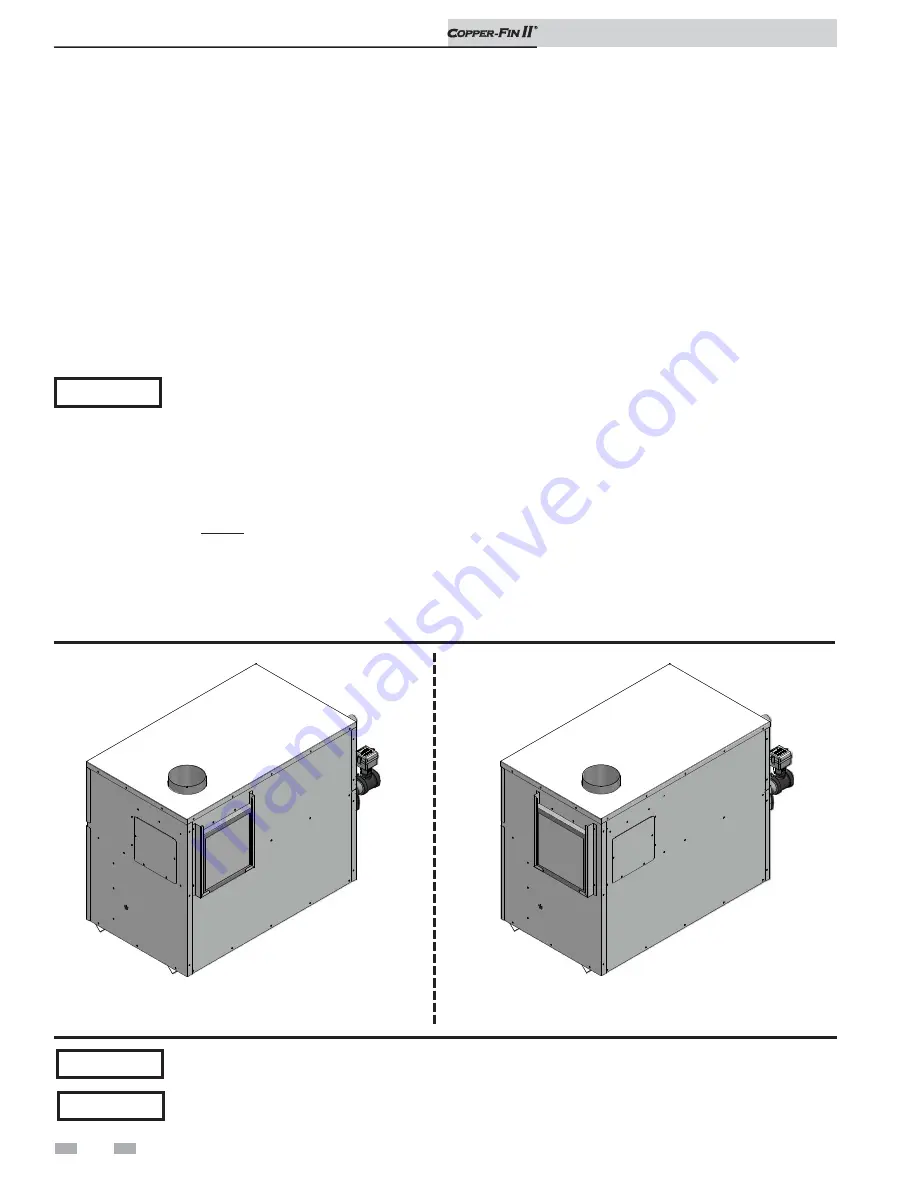

For convenience and flexibility, you can direct the combustion

air inlet from either the back or right side of the unit. To arrange

the combustion air inlet for side entry, follow the steps below:

1. Remove the metal panel from the unit’s side wall (see

FIG. 1-6).

2. Remove screws from the air filter/bracket assembly.

3. Move the filter/bracket assembly from the rear of unit to the

side opening (see FIG. 1-7).

4. Attach filter/bracket assembly to the unit’s side using the

pre-drilled screw holes.

5. Attach the metal panel to the rear combustion air opening

to seal it off.

Figure 1-6_Metal Panel Covering Side Combustion

Air Inlet

Figure 1-7_Moving Air Filter / Bracket Assembly from

Rear of Unit to Side

CAUTION

During construction the air filter should be checked more frequently to ensure it does not become clogged with

combustion dirt and debris.

NOTICE

Sustained operation of an appliance with a clogged filter may result in nuisance operational problems, bad

combustion, and non-warrantable component failures.

Use of filters having MERV (

Minimum

Efficiency Reporting Value

) ratings higher than

4 is not recommended. Higher efficiency

low-micron filters can limit combustion

air leading to either nuisance problems or

potential component damage if used over

prolonged periods of time. Filters having

a MERV rating of 5 to 6 may be used

on a limited basis during the construction

phase of a project provided they are replaced

once filter loading becomes apparent. After

the construction phase is completed, it is

recommended that the filter be changed to a

4 or lower MERV disposable type filter.

NOTICE