Installation & Operation Manual

51

7

Operating information

(continued)

General

How the appliance operates

The Copper-fin II uses a copper finned tube heat exchanger to

transfer heat from the flue products to the water. An electronic

control module monitors various inputs to initiate a call for

heat. The blower provides both primary and secondary air to

the burner and forces the flue products out of the combustion

chamber and into the vent system. The control module

regulates the blower speed and firing stages, based upon the

heat demand. Gas valves regulate the amount of gas supplied

for the firing stages, which is then mixed with the combustion

air supplied to the burner.

0 - 10V input (set point or power)

The Copper-fin II can be controlled by a Building Management

System (BMS) using a 0 - 10 VDC signal. The control can be

configured by the installer to use this signal to either control set

point or firing rate.

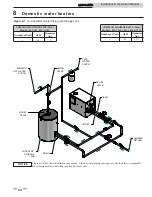

DHW priority (boiler only)

The SMART SYSTEM control module allows connection of a

DHW thermostat or tank sensor to the low voltage connection

board. When the DHW thermostat or tank sensor calls for heat,

the module activates the DHW pump, shuts down the boiler

pump, and immediately sets the target outlet water temperature

to 180°F (82.2°C). This provides automatic priority heat

allocation to the indirect water heater for maximum response

and recovery. The DHW pump continues for 30 seconds after

the heating cycle to deliver the most possible heat.

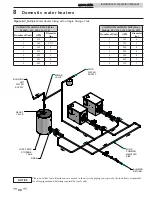

DHW / SH (space heating) cycling (boiler only)

If an indirect DHW call for heat is received while a space heating

call is in progress, the control will start the DHW pump and

shut the boiler pump off. The system pump will remain on.

If the space heating call is still active while the DHW call is in

operation, the control will wait for 30 minutes (time adjustable

by installer) then it will switch back to the space heating

demand. The control will switch back and forth until one of the

heat demands end.

Programmable controlling sensor (boiler only)

The control module is programmed to use the outlet sensor

as the control sensor by default. If a system supply sensor

is connected, the control automatically uses it as the control

sensor. The control sensor can be changed by the installer to the

inlet sensor. In this case, if a system return sensor is installed, the

control automatically uses it as the control sensor. If the inlet

sensor is chosen as the controlling sensor, it is recommended

that the system supply sensor be installed for the best system

performance.

Anti-cycling (boiler only)

After the set point has been satisfied, the control will delay the

next burner cycle for a set time period (time is adjustable by the

installer). The time delay will be bypassed if the system return

temperature drops too far during the delay.

Boiler, system, and DHW pump control

When a space heating call for heat starts and no DHW call is on,

the system and boiler pumps are turned on. As long as the space

heating call for heat is on, the system pump will remain on. If

a DHW call for heat is on, the boiler pump will wait to turn

on until just before the DHW pump turns off. After the space

heating call for heat ends, both pumps will run for an additional

period of time.

When a DHW call for heat starts, the DHW pump is turned on.

If a space heating call for heat was on, the boiler pump will turn

off a few seconds after the DHW pump turns on.

NOTICE

If an inline high gas pressure regulator is

used, it MUST BE of the lockup type and

be located a minimum of 10 feet from

the appliance. Failure to do so may result

in insufficient gas volume supplied to the

appliance.

NOTICE

If a pressure drop of more than 2" water

column occurs between Standby (static)

Mode and Operating (dynamic) Mode, a

gas volume problem exists. Contact the gas

utility, gas supplier, qualified installer, or

service agency to determine the necessary

steps to provide the proper gas volume to

the appliance.

How the control module operates

The SMART SYSTEM control module receives input from

appliance sensors and external devices. The control module

activates and controls the blower and gas valves to regulate heat

input and switches the boiler, Domestic Hot Water (DHW),

and system pumps on and off as needed. The user programs the

module to meet system needs by adjusting control parameters.

These parameters set operating temperatures and appliance

operating modes. Boiler operation can be based on boiler

outlet water temperature, boiler inlet water temperature, system

supply temperature, or system return temperature, depending

on the parameter setting. Water heater operation can be based

on a tank sensor or a tank thermostat.

Control inputs and outputs

Staging S1 - S4

The S1 input tells the boiler to provide water for space heating.

The S2 - S4 inputs are used when a sequencer controls the

boiler.

Tank Aquastat

This input tells the boiler to provide water for heating a

domestic hot water tank.