Installation & Operation Manual

62

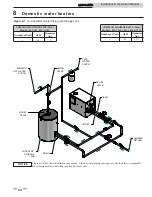

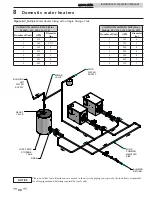

8

Domestic water heaters

This section applies only to those appliances used to supply

domestic hot water, installed with a storage tank(s). A circulating

pump MUST be installed in the piping assembly to the storage

tank and valves used to control water velocity through the

appliance. Proper water velocity is important for correct

operation of your water heater.

This section contains specific instructions for those appliances

used to supply domestic hot water. All warnings, cautions,

notes and instructions in the general installation and operation

sections apply to these instructions. Water heaters are designed

for installation with a storage tank. The operation of the

circulating pump, proper sizing of the piping between the tank

and heater and the control of water velocity, as explained in

this section, are important for correct operation of your water

heater.

NOTICE

To ensure proper velocity through the heat

exchanger, it is necessary to regulate the

temperature rise across the heat exchanger

from inlet to outlet. This must be done

on initial installation and periodically

rechecked. With the correct temperature

rise across the heat exchanger when the

water heater is firing at 100% of rated

input, you may be assured of the proper

velocity in the tubes. This will yield long life

and economical operation from your water

heater.

Excessive lime/scale build-up in the heat

exchanger tubes is a result of restricted flow

and too little velocity in the tubes. Excessive

pitting or erosion in the tube is caused by

high water flow and too much velocity

through the tubes. Care should be taken

to measure temperature rise and maintain

velocity as follows:

Initial set-up of maximum water flow

On initial start-up of the Copper-fin II the maximum water flow

through the heat exchanger must be manually set before normal

operation begins.

If higher flow rates are required through the water heater, an

optional Cupro Nickel heat exchanger is available. Consult the

factory for specific application requirements.

The heat exchanger is capable of operating within the design

flow rates required for the water heater, storage tank(s), and

connecting piping. Erosion of the finned copper tubes may

occur if the flow rate exceeds the maximum allowable flow rate

through the water heater. The maximum flow rate through the

water heater must be adjusted. Maximum flow on Models 402

- 752 is 55 GPM and 90 GPM on Models 992 - 2072. Flow rate

can be determined by measuring the temperature rise through

the water heater when it is firing at full rate input.

1. The pump must run continuously when the burner is

firing.

2. With the pump running and the burner in the water heater

in the off cycle, the inlet water temperature and outlet water

temperature readings on the Operator Interface should read

approximately the same temperatures. Water Temperature

Rise on the Operator Interface should read near zero.

3. Turn the water heater on and allow time for the temperature

to stabilize. The Service Mode can be used to force the water

heater to run at full fire. See the Copper-fin II Service Manual

for a detailed explanation of the Service Mode. Check the

water temperature rise in the Operator Interface when the

burner is firing at 100% of rated input.

4. Compare the water temperature rise in the Operator

Interface with the required temperature rise. Should

adjustment be needed, proceed as follows.

TABLE - 8A

MAXIMUM WATER FLOW

CAUTION: The maximum flow rate through a Copper-fin II

water heater with a copper heat exchanger must be set to provide

and not exceed the following flow:

Model

Maximum Flow

402, 502, 652, and 752

55 GPM

992, 1262, 1442, 1802, and 2072

90 GPM

TABLE - 8B

TEMPERATURE RISE AT FULL RATE FIRE

55 AND 90 GPM FLOW

Model

Temperature Rise °F

402

12

502

15

652

20

752

23

992

19

1262

24

1442

27

1802

34

2072

39