36

www. lochinvar .com

100221773_2000189439_Rev. 01

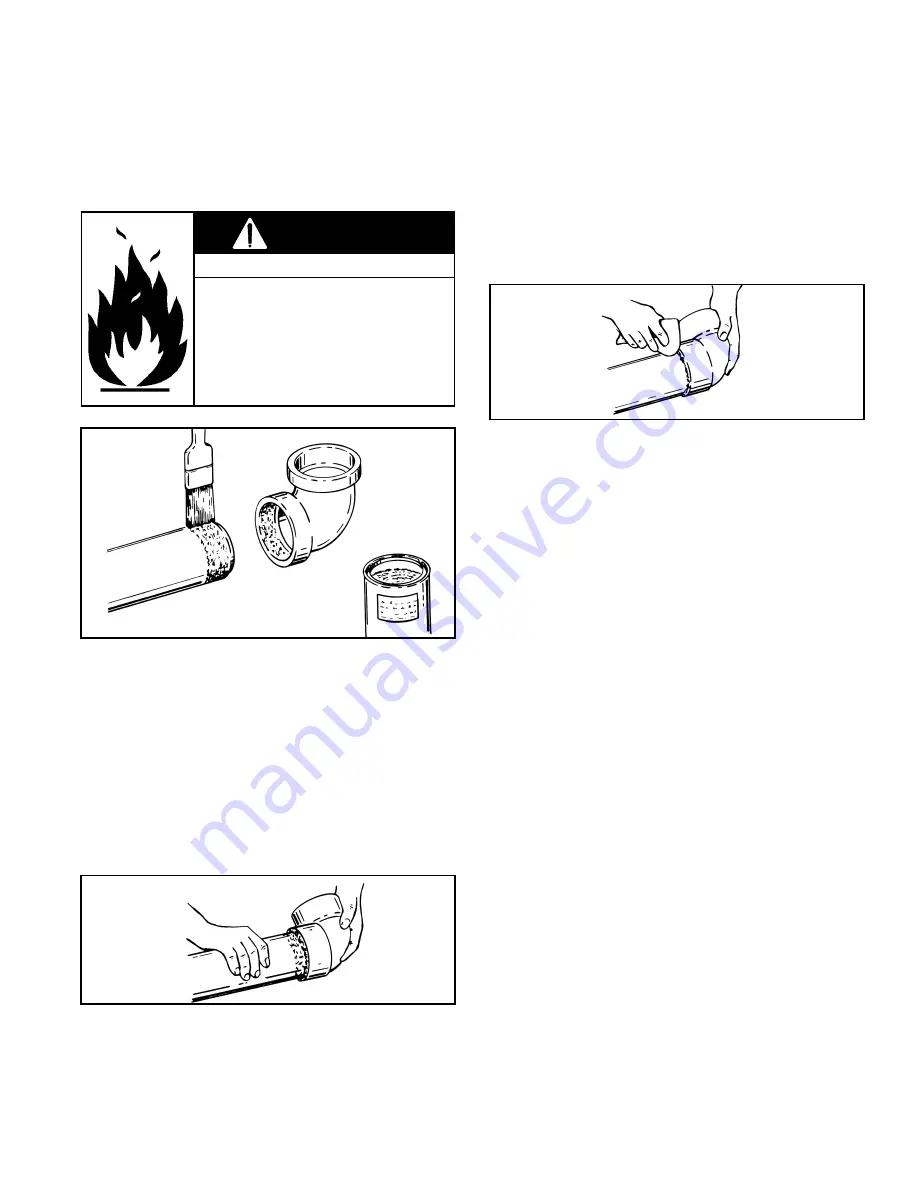

E. Application of solvent cement

•

Apply solvent cement evenly and quickly

around outside of pipe at a width a little

greater than the depth of the fitting socket.

•

Apply a light coat of cement evenly around

the inside of the fitting socket. Avoid puddling.

•

Apply a second coat of cement to the pipe

end.

•

Cans of cement and primer should

be closed at all times when not in

use to prevent evaporation of

chemicals and hardening of cement.

•

They are also very flammable and

should be kept away from heat or

flame.

Fire Hazard

WARNING

Figure 43.

F. Joint assembly

Working quickly, insert the pipe into the fitting

socket bottom and give the pipe or fitting a 1/4 turn

to evenly distribute the cement. Do not continue

to rotate the pipe after it has hit the bottom of

the fitting socket. A good joint will have sufficient

cement to make a bead all the way around the

outside of the fitting hub. The fitting will have a

tendency to slide back while the cement is still wet

so hold the joint together for about 15 seconds.

Figure 44.

G. Cleanup and joint movement

Remove all excess cement from around the pipe

and fitting with a dry cotton rag. This must be done

while the cement is still soft.

The joint should not be disturbed immediately

after the cementing procedure, and sufficient time

should be allowed for proper curing of the joint.

Exact drying time is difficult to predict because

it depends on variables such as temperature,

humidity and cement integrity. For more specific

information, you should contact your solvent

cement manufacturer.

Figure 45.