31

10.15

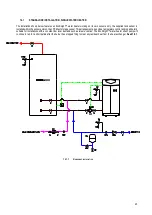

TYPE C

43

(U DUCT)

This appliance can operate on a U-Duct common flue system. The maximum lengths for the interconnecting flue can be found in

Concrete components of the U-Duct must meet the requirements of BS EN 1858.

Model No.

Nominal Flue

Diameter

Mass Rate @ 100%

Mass Rate @ 23%

Mass Rate @ 100%

Mass Rate @ 23%

(@ 9% CO2) (G20)

(@ 9% CO2) (G20)

(@ 10.5% CO2) (G31)

(@ 10.5% CO2) (G31)

EKW46CE

80+/-0.6

16.0g/s

3.7g/s

16.7g/s

3.8g/s

EKW61CE

80+/-0.6

22.3g/s

5.1g/s

23.2g/s

5.3g/s

EKW86CE

100+/-0.6

30.4g/s

7.0g/s

31.6g/s

7.3g/s

10.15.1

FLUE

GAS

MASS

RATES

10.16

C

53

(TWIN PIPE) FLUE SYSTEMS

Flue system specifications

MANUFACTURER MUELINK AND GROL (M&G)

TEMPERATURE CLASS T120

FLUE GAS MATERIAL PP

Each Twin-Pipe starter assembly includes the items shown in the tables below

Item No EKWTF001

TWIN-PIPE FLUE STARTER ASSEMBLY

Kit contains components to start the connection to the appliance only

MODELS EKW46CE,EKW61CE

COMPONENTS INCLUDED

Item No.

Description

Number

Quantity

M75256

AIR INLET TRANSITION Ø80mm ALU

1

1

M85279

SAMPLING POINT Ø80mm PP

2

1

Item No EKWTF002

TWIN-PIPE FLUE STARTER ASSEMBLY

Kit contains components to start the connection to the appliance only

MODELS EKW86CE

COMPONENTS INCLUDED

Item No.

Description

Number

Quantity

M75257

AIR INLET TRANSITION Ø100mm ALU

1

1

M85189

SAMPLING POINT Ø100mm PP

2

1

When installing the EcoKnight™ on a C

53

twin pipe flue system, the Lochinvar Twin pipe flue starter assembly must be fitted first

including the flue temperature sensor.

Summary of Contents for ECOKNIGHT EKW116CE

Page 28: ...28 Max distance between brackets ...

Page 29: ...29 ...

Page 30: ...30 ...

Page 34: ...34 ...

Page 35: ...35 ...

Page 55: ...55 15 8 WIRING DIAGRAM 15 8 1 WIRING DIAGRAM ...

Page 56: ...56 15 9 LADDER DIAGRAM 15 9 1 LADDER DIAGRAM ...

Page 87: ...87 ...

Page 88: ...88 ...