30

PIN

CONNECTION

NOTES

1-2

EXTERNAL

CONTROL

When the heater is to be controlled by a 0-10V DC analogue output from a Building Management System (BMS), the

0V line should be connected to pin 1 and the 0-10V line should be connected to pin 2.

3-6

SEQUENCING

If the heaters are to be operated in a cascade, shielded 2-wire twisted pair communication cable should be used. The

shielding should be connected to pin 3 or 6 and then all “A” terminals (pin 5) should be linked together and all “B”

terminals (pin 4) should be linked together.

7-8

TANK SENSOR

The chosen flow temperature sensor (

Section 10.6: FLOW TEMPERATURE SENSOR

) should be connected to pins

7&8. Where remote control over the water heater is required, the sensor wiring should be connected using screened

cable to a volt-free contact. The contact should be configured to close when heat is required and open to prevent the

water heater from operating. For further information, please refer to

Figure 11.3

.

9-10

TANK

THERMOSTAT

This connection should not be used. The supplied temperature sensor should be connected to pins 7&8. For further

information, please refer to

Section 10.6: FLOW TEMPERATURE SENSOR

11-12

RUNTIME

CONTACTS

An internal volt free contact across pins 11&12 will close in the event of the burner operating. This connection can be

used by a BMS to monitor the operation of the heater.

13-14

ALARM

CONTACTS

An internal volt free contact across pins 13&14 will close in the event of the heater locking out. This connection can

be used by a BMS to monitor the operation of the heater.

15-16

FLOW SWITCH

If a flow switch is to be used to ensure the primary pump is operating, the link should be taken out of pins 15&16 and

the flow switch wiring installed. If there is no continuity across the terminals the heater will not fire.

17-18

GAS PRESSURE

SWITCH

If a gas pressure switch is to be used to ensure the incoming gas pressure is correct, the link should be taken out of

pins 17&18 and the gas pressure switch wiring installed. If there is no continuity across the terminals the heater will

not fire.

19-20

AUX. PROVING

DEVICE

If an auxiliary device such as a fan dilution system or mechanical ventilation system is to be used, the link should be

taken out of pins 19&20 and the auxiliary deice safety circuit wiring installed. If there is no continuity across the

terminals the heater will not fire.

21-22

AUX. DEVICE

PILOT SUPPLY

When the heater gets a call for heat, a 24VAC supply becomes present on pin 22. Used in conjunction with the

ground pin (pin 21), these terminals can be used to send a signal to energise an auxiliary device such as a fan dilution

system or mechanical ventilation system.

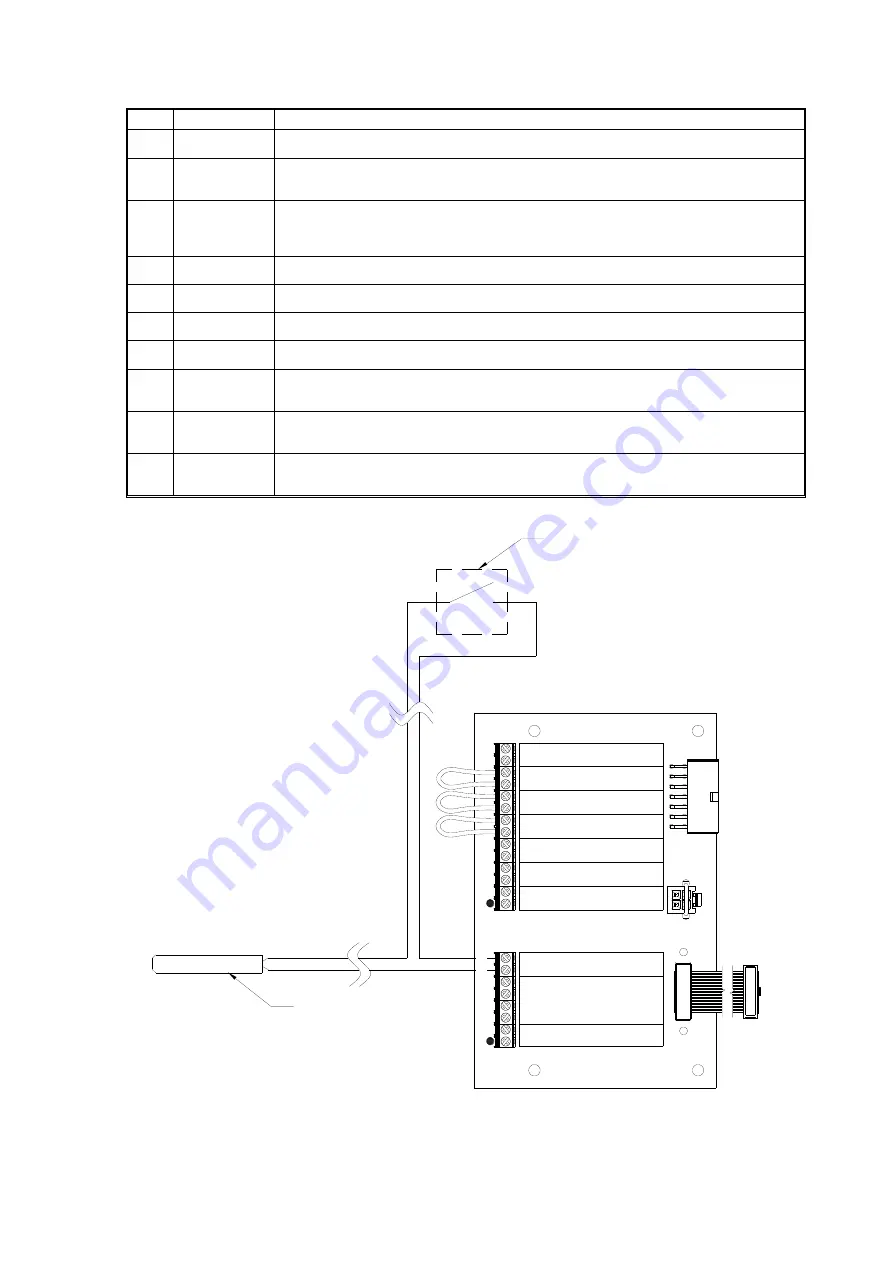

TABLE 11.3

LOW VOLTAGE CONNECTION TERMINAL DETAILS

FIGURE 11.3

TIME CONTROL WIRING

AUX. DEVICE

PILOT SUPPLY

24VAC

GND

AUX. DEVICE

PROVING

GAS PRESSURE

SWITCH

FLOW

SWITCH

ALARM

CONTACTS

RUNTIME

CONTACTS

TANK

SENSOR

SHIELD GROUND

0-10VDC EXTERNAL

GND CONTROL

TANK THERMOSTAT

A

B

SHIELD GROUND

SEQUENCING

LOW

WAT

E

R

C

UTOF

F

CN1

CN2

CN3

CN4

CN5

9

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

FLOW TEMPERATURE SENSOR

CONTROL CONTACT