60

RELIEF

VALVE

At least once a year, the temperature and pressure relief valve and safety valve should be checked to ensure that they operate correctly. To

check the valves, the manual override levers should be operated several times. The valves should seat properly and operate freely.

If water does not flow, drain the heater, remove the inoperative valve and inspect for obstructions or corrosion. Replace with a new valve of the

recommended size as necessary.

FLUE

SYSTEM

Examine the exhaust and air intake system every 12 months. Points of inspection are as follows:

1.

Check for obstructions and/or deterioration of flue pipe and terminal. Replace immediately where needed.

2.

Check the terminal for any foreign material and remove as necessary

3.

Check all flue system connections for leakage and reseal as required.

4.

Check that ventilation grilles comply with current regulations.

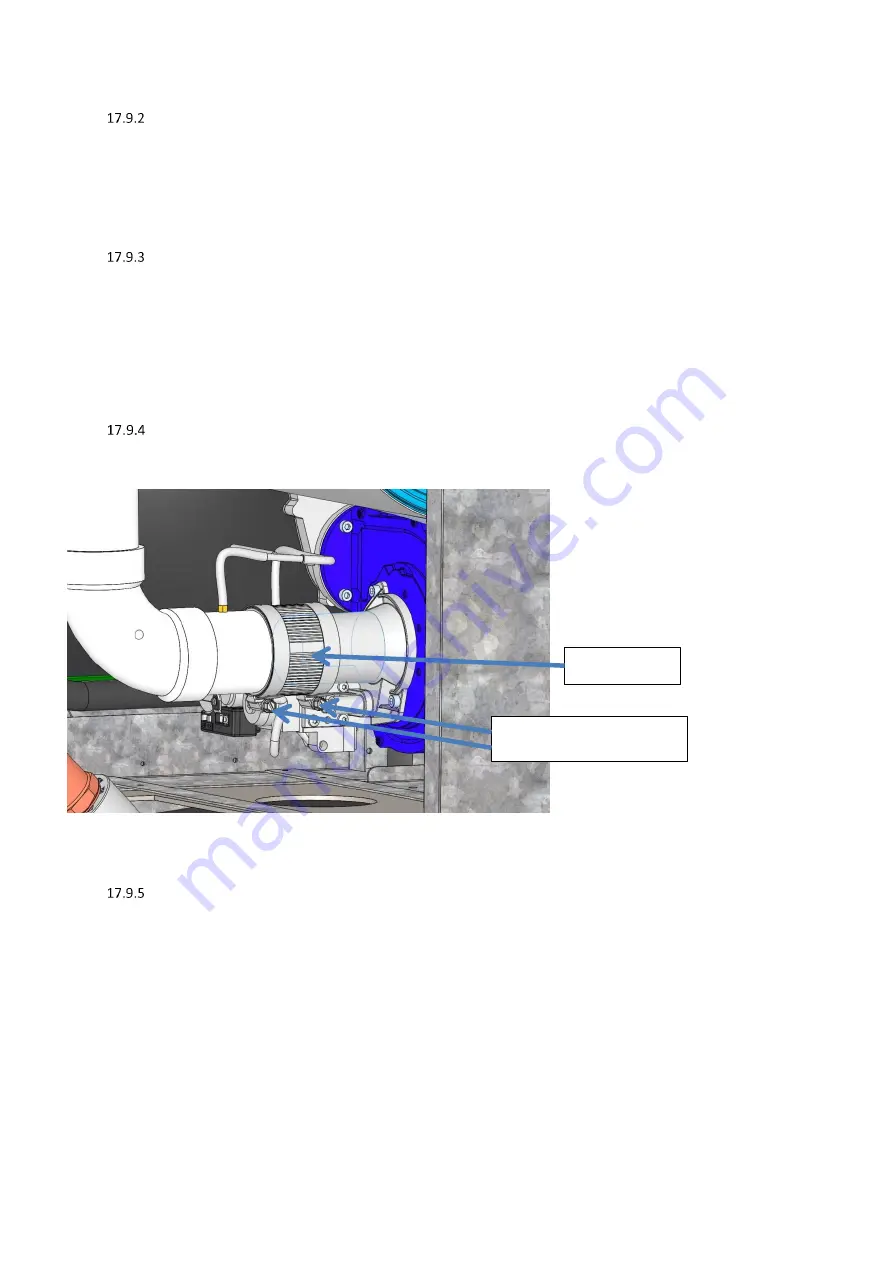

AIR

INTAKE

CONNECTION

During the annual maintenance inspection the coupling piece between the fan housing and air inlet tube should be checked to ensure it is

correctly fitted and secure.

Fig 15.9 Air intake connection

CONDENSATE

NEUTRALISATION

KIT

If fitted, the condensate neutralisation kit will require replacing after 12 months of operation. Please refer to the item specific instructions for

further details.

Coupling Piece

Check and tighten if required

Summary of Contents for EcoShield SHW116-410CE

Page 2: ...2 ...

Page 9: ...9 EXPLODED VIEW DRAWINGS ...

Page 27: ...27 Max distance between brackets ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 34: ...34 ...

Page 47: ...47 13 9 LADDER DIAGRAM LADDER DIAGRAM ...

Page 71: ...71 NOTES ...

Page 72: ...72 N ...