68

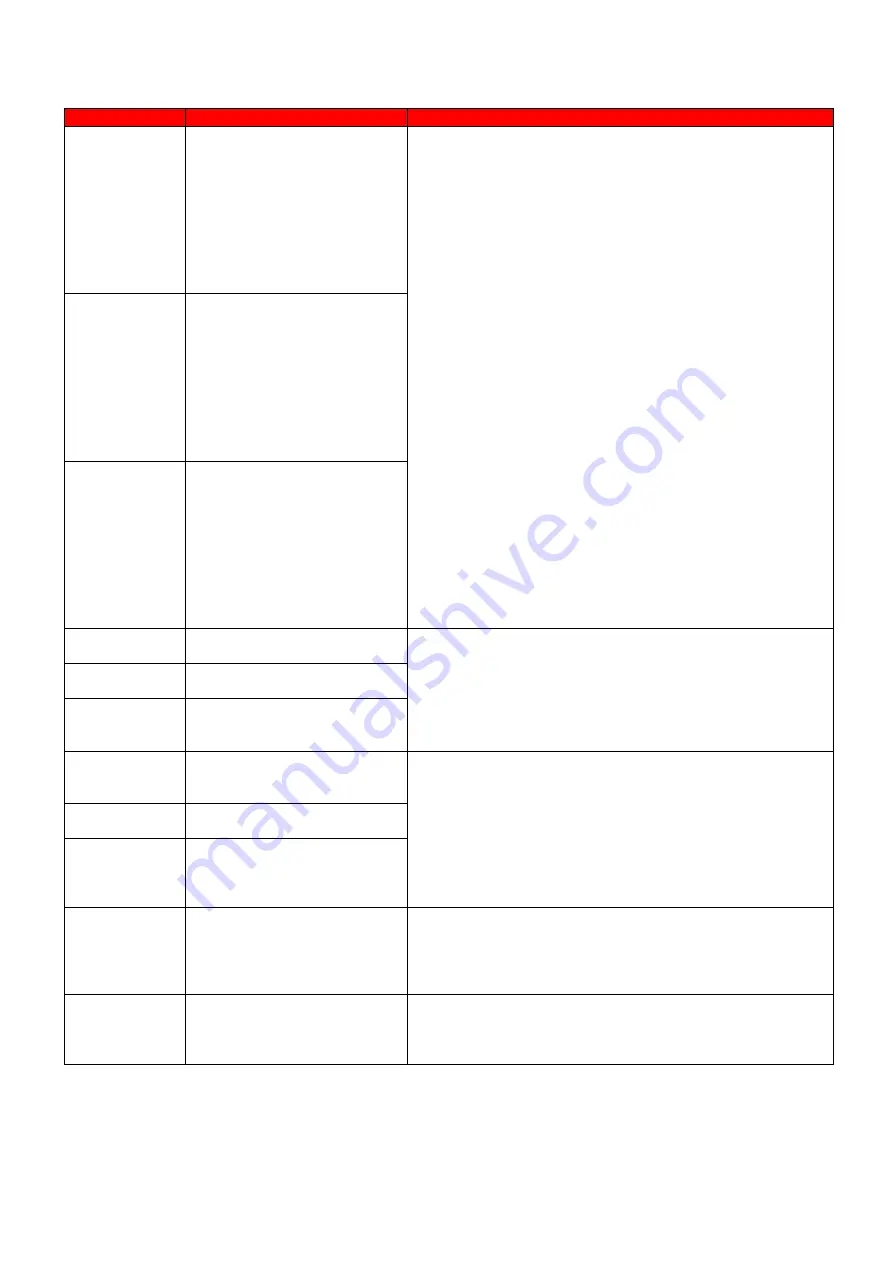

Error Codes

Description

Corrective Action

E11

Flame signal lost 4 times

Inspect spark electrode and associated wiring for damage and correct

connection, replace if required

Check for correct electrical earthing

Check incoming gas supply pressure is correct refer to section 9.0 gas

supply

Verify the plastic hose from the gas valve to the air inlet is connected and

undamaged

Verify the air intake/flue exhaust pipes are correctly installed and that there

are no obstructions

Check for 24v to the gas valve at the 2 pin connector on the side of the

main control board during ignition. If no voltage present replace the control

board

If 24v present at the main control board, check the wiring between the

board and the gas valve. Replace if required. Do not disconnect the wiring

from the gas valve and attempt to measure a voltage at that point, the

board will detect the gas valve is not connected and display a gas valve

fault.

If 24v is present check the gas valve is opening using a manometer

connected to the outlet of the gas valve. During pre-purge there should be

a negative pressure when the valve is energized there should be a positive

pressure. If these do not occur replace the faulty gas valve.

Inspect flame sensor and associated wiring, replace if required.

Inspect and clean the heat exchanger.

Inspect the burner and clean, replace if required.

Replace the main control board.

E12

Failed main burner ignition attempt 4

times

n05

The fan speed is being increased due

to the flame current going below

5microcamps

E13

The flue temperature has exceeded

121

o

C

Inspect and clean the heat exchanger

Inspect the flue sensor, measure the resistance of the sensor and compare

with table

.,replace if required

Verify the air intake/flue exhaust pipes are correctly installed and that there

are no obstructions

Replace the main control board.

b05

The flue temperature has exceeded

115

o

C

n04

The fan speed is being limited due to

the flue temperature exceeding

100

o

C

E15

The outlet temperature has exceeded

the 98

o

C manual reset high limit

setting

Verify the system is full of water and all air has been purged from the

system, pay particular attention to the EcoShield™ heat exchanger

Verify the water heater has been piped correctly

Check the shunt pump is operating, if not check wiring back to the main

control board

Replace the main control board if required

If the wiring is Ok and there is 230v to the pump replace the pump

Check resistance of water sensors with table

, replace sensor if

required.

b03

The outlet water temperature has

exceeded 90

o

C

n02

The fan speed is being limited due to

the outlet water temperature

exceeding 85

o

C

E18

The control module reads an

excessive DT between the 2 sensors

Check wiring to sensor, make sure all is correctly connected and

undamaged

Check resistance of water sensors with table

required.

Replace control module

E19

One or both flue sensors is open or

shorted

Inspect the flue sensors, measure the resistance of the sensors and

compare with table

.,replace if required

Replace control module

Continued over page

Summary of Contents for EcoShield SHW116-410CE

Page 2: ...2 ...

Page 9: ...9 EXPLODED VIEW DRAWINGS ...

Page 27: ...27 Max distance between brackets ...

Page 28: ...28 ...

Page 29: ...29 ...

Page 34: ...34 ...

Page 47: ...47 13 9 LADDER DIAGRAM LADDER DIAGRAM ...

Page 71: ...71 NOTES ...

Page 72: ...72 N ...