27

completely reset and continues to release water, immediately close

the cold water inlet to the heat pump, follow the draining

instructions in the storage tank manual, and replace the

temperature-pressure relief valve with a properly rated/sized

new one.

If you do not understand these instructions or have any questions

regarding the temperature-pressure relief valve call the toll

free number listed on the back cover of this manual for technical

assistance.

CLEANING INTERNAL INSULATION

Inspect the internal insulation on a yearly basis for any microbial

growth. The insulation never has to be cleaned unless microbial

growth is detected. If microbial growth is detected, follow the

removal steps below:

1. Disconnect all power to the unit and follow the prescribed

lock-out/tag-out procedure.

2. Wear the prescribed personal protective equipment

prescribed from the cleaning product instructions.

3. Remove as much dirt and organic material from the insu-

lation using a vacuum device with a HEPA fi lter (99.97%

effi

cient at 0.3 micron particles). Be careful not to tear the

insulation during the cleaning procedure.

4. Apply the microbial cleaning agent as prescribed by the

application and usage instructions.

5. Allow the unit to dry thoroughly.

6. If necessary, apply an anti-microbial agent on the insulation

per the instructions provided on the product label.

Discard collected microbial contaminants as required by local

or state codes.

CHECKING REFRIGERANT CHARGE

Servicing of the refrigeration circuit must only be performed

by agencies or individuals possessing Type II or Universal

certification as defi ned in Section 608 of the Clean Air Act.

See Qualifi cations on page 3.

This HPWH unit is factory charged with 134a refrigerant. See

the rating label on the HPWH unit and Table 9 for refrigerant

charge by weight. It should not be necessary to add or

remove refrigerant during installation or start up. Refrigerant

lost during frequent refrigerant pressure testing can cause

low refrigerant conditions. Air and water fl ow should always

be checked fi rst to eliminate other potential problems before

checking the refrigerant charge.

CHECK WATER TEMPERATURE RISE

Always check water temperature rise through the HPWH

unit’s internal heat exchanger before checking the refrigerant

charge. See Start Up on page 19 for information on how to

measure the water temperature rise.

If the measured water temperature rise during start up was

within 8°F to 12°F (4°C to 7°C) checking the charge is not

necessary unless other conditions warrant testing.

If the measured temperature rise through the HPWH unit is

less than 8°F (4°C) checking the charge is not necessary

unless other conditions warrant testing. Short water piping

runs between the HPWH and the storage tank will produce

lower temperature rises and are not problematic.

If the measured temperature rise through the HPWH unit is

more than 12°F (7°C) check for restrictions in the inlet and outlet

water piping connected between the HPWH unit and the storage

tank.

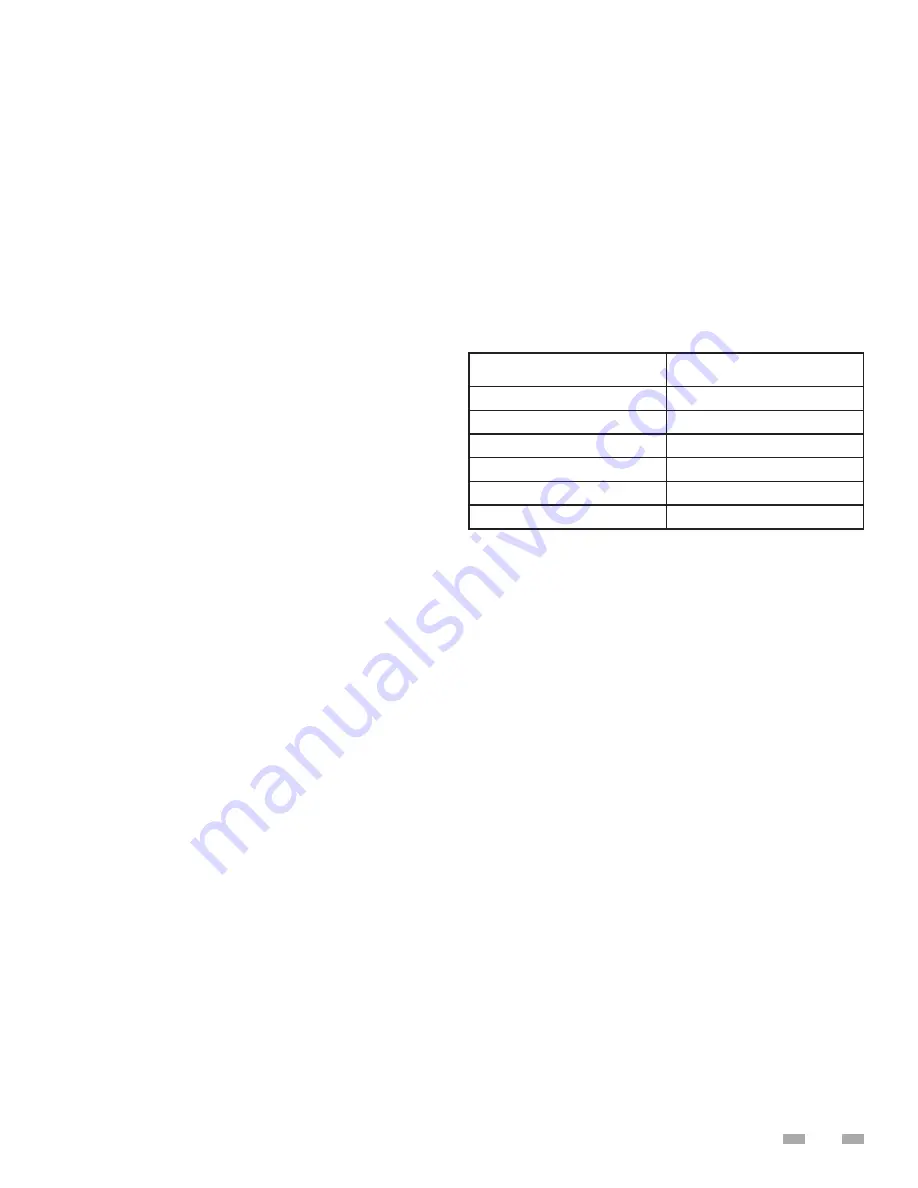

TABLE 9

SUPERHEAT CALCULATION

1. Measure and record the suction pressure at the

suction line pressure access port inside the unit.

2. Convert the recorded suction pressure to saturated

temperature.

3. Measure the suction line temperature near the suction

line pressure access port inside the unit.

4. Compare the suction line temperature to the saturated

temperature in Table 10 on the next page.

5. The di

ff

erence between saturated temperature and

suction line temperature is the superheat. Superheat

normal range should be 8°F to 12°F (4.4°C to 6.7°C)

BRAZE PLATE CLEANING INSTRUCTIONS

In some applications the heat exchanger may be subjected

to severe fl uid conditions, including high temperature hard

water conditions, causing accelerated scaling and corrosion

rates, and will diminish performance.

It is important to establish regular cleaning schedules, A 5%

solution of Phosphoric Acid or Oxalic Acid may be considered.

Other types of solutions can be obtained from your local

wholesaler. Make sure cleaning solution is applicable for stainless

steel and copper and all directions are followed.

Do not heat solution. Be sure to fl ush heat exchanger with

fresh water after cleaning. See Figure 12 on the next page.

Model

Factory Charge R134A

WHP025

7 #

WHP060

14 #

WHP090

21 #

WHP125

25 #

WHP185

30 #

WHP250

50 #

Summary of Contents for HS 50 Series 100

Page 2: ......

Page 10: ...6 WATER TO WATER CYCLE ...

Page 32: ...28 TABLE 10 FIGURE 12 ...

Page 41: ...37 Technical Support 1 833 447 3201 ...

Page 42: ...38 Service Log Issue Description Date Servicer ...

Page 43: ...39 Service Log Issue Description Date Servicer ...

Page 44: ......