4 • Residen al Electric Water Heater Use and Care Guide

IMPORTANT SAFETY INFORMATION

T

o reduce the risk of property

damage, serious injury or death,

read and follow the precau ons below,

all labels on the water heater, and

the safety messages and instruc ons

throughout this manual.

RISKS DURING INSTALLATION

AND MAINTENANCE

Electric Shock Risk

Contact with the electrical

parts in the junction box and

behind the access doors can

result in severe injury or death from

electrical shock:

• Disconnect power by opening the

circuit breaker or removing the

fuses before installing or servicing.

• Use a non-contact circuit tester to

confirm that power is off before

working on or near any electrical

parts.

• Replace the junction box cover and

access doors after servicing.

Lifting Risk

WARNING!

The

water heater is

heavy. Follow these

precau ons to

reduce the risk of property damage,

injuries from li ing or impact injuries

from dropping the water heater.

• Use at least two people to lift the

water heater.

• Be sure you both have a good grip

before lifting.

• U se an appliance dolly or hand

truck to move the water heater.

RISKS DURING OPERATION

Scalding Risk

This water heater

can make water hot

enough to cause

severe burns instantly, resulting in

severe injury or death.

• Feel water before bathing or s how-

ering.

• To reduce the risk of scalding,

install Thermostatic Mixing Valves

(temperature limiting valves) at

each point-of-use. These valves

automatically mix hot and cold

water to limit the temperature at

the tap. Mixing valves are available

from your local plumbing supplier .

Follow manufacturer’s instructions

for installation and adjustment of

the valves.

• The thermostat(s) on this water

heater have been factory set to

approximately 120°F to reduce the

risk of scalding. Higher tempera-

tures increase the risk of scalding,

but even at 120°F, hot water can

scald. If you choose a higher tem-

perature, Thermostatic Mixing

Valves located at each point-of-use

are particularly important to help

avoid scalding.

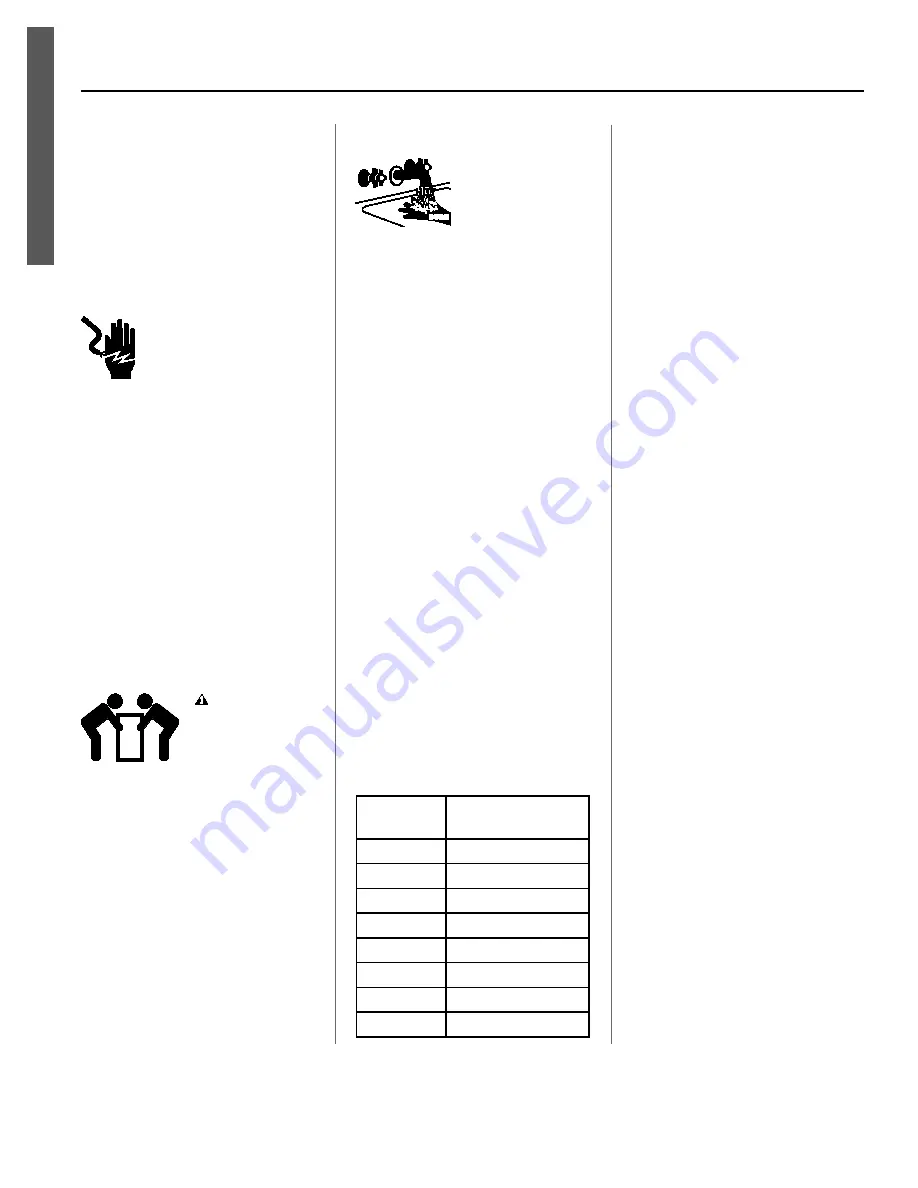

Temperature Time to Produce a

Serious Burn

120°F (49°C)

More than 5 minutes

125°F (52°C)

1½ to 2 minutes

130°F (54°C)

About 30 seconds

135°F (57°C)

About 10 seconds

140°F (60°C)

Less than 5 seconds

145°F (63°C)

Less than 3 seconds

150°F (66°C)

About 1½ seconds

155°F (68°C)

About 1 second

For informa on about changing the

factory thermostat se ng(s), refer to

the “Adjus ng Temperature” sec on in

this manual (“Step 10” on page 15).

Even if you set the water heater

thermostat(s) to a low se ng, higher

temperatures may occur in certain

circumstances:

• In some cases, repeated small

draws of water can cause the

hot and cold water in the tank to

“stack” in layers. If this happens,

the water can be as much as thirty

degrees hotter than the thermo-

stat setting. This temperature varia-

tion is the result of your usage pat-

tern and is not a malfunction.

• Water temperature will be hot-

ter if someone adjusted the

thermostat(s) to a higher setting.

• Problems with the thermostat(s),

or other malfunctions may result in

higher than expected water tem-

peratures.

• If the water heater is in a hot envi-

ronment, the water in the tank can

become as hot as the surrounding

air, regardless of the thermostat

setting.

• If the water supplied to the water

heater is pre-heated (for example,

by a solar system) the temperature

in the tank may be higher than the

water heater’s thermostat setting.

To reduce the risk of unusually hot

water reaching the

fi

xtures in the

house, install Thermosta c Mixing

Valves at each point-of-use.

If anyone in your home is at par cular

risk of scalding (for example, the el-

derly, children, or people with disabili-

es) or if there is a local code or state

law requiring a certain water tempera-

ture at the hot water tap, then these

S

AFETY