2

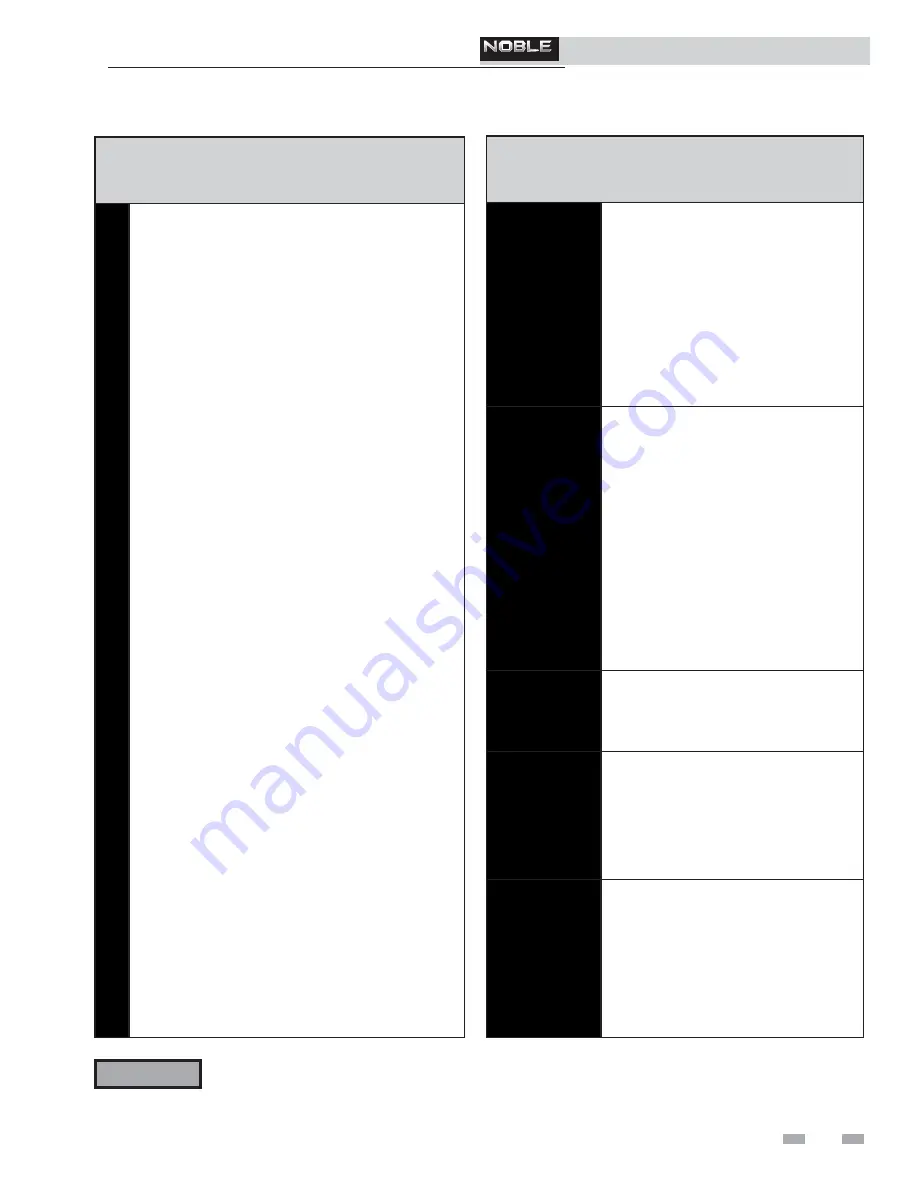

Maintenance schedule

5

Service technician

General:

• Reported problems

• Inspect interior; clean and vacuum if

necessary

• Clean condensate trap and fill with fresh

water

•

Check for leaks (water, gas, flue,

condensate)

• Verify flue and air lines in good condition

and sealed tight

• Check system water pressure/system

piping/expansion tank

• Check control settings

• Ignition and flame sense electrodes

(sand off any deposits; clean and

reposition)

• Wiring and connections

•

Perform start-up checkout and performance

verification per Section 10 in the Noble

Combi Boiler Installation and Service

Manual.

• Flame inspection (stable, uniform)

• Flame signal (at least 4 mA)

•

Clean the heat exchanger if flue

temperature is more than 54°F above

return water temperature.

If combustion or performance indicate

need:

• Clean heat exchanger

•

Remove and clean burner using

compressed air only

• Clean the blower wheel

Owner maintenance

(see pages 6 - 8 for detailed instructions)

Daily

• Check boiler area

•

Check pressure/temperature

gauge

Monthly

• Check vent piping

• Check air piping

• Check air and vent termination

screens

• Check relief valve

• Inspect condensate drain system

Periodically

• Test low water cutoff (if used)

• Reset button (low water cutoff)

Every

6 months

• Check boiler piping (gas and

water) for leaks

• Operate relief valve

End

of season

months

• Shut boiler down (unless boiler

used for domestic hot water)

WARNING

Follow the maintenance procedures given throughout this manual. Failure to perform the service and

maintenance or follow the directions in this manual could result in damage to the boiler or system,

resulting in severe personal injury, death, or substantial property damage.

ANNUAL START-UP

User’s Information Manual

F I R E T U B E C O M B I

™