11

6

Parameters

(continued)

Changeable parameters

The following is a brief discussion of the changeable

parameters, their default settings, the range of adjustment,

and their location. The title for the parameters may differ

slightly from the PC to the boiler display. To prevent

confusion, the boiler display version will be listed in

parenthesis.

Set 1: System setup

Set 1 is accessed by clicking on

Parameters

at the top of the

Main Screen window (FIG. 6-1), then on

Set 1: Control Setup

on the pull-down menu.

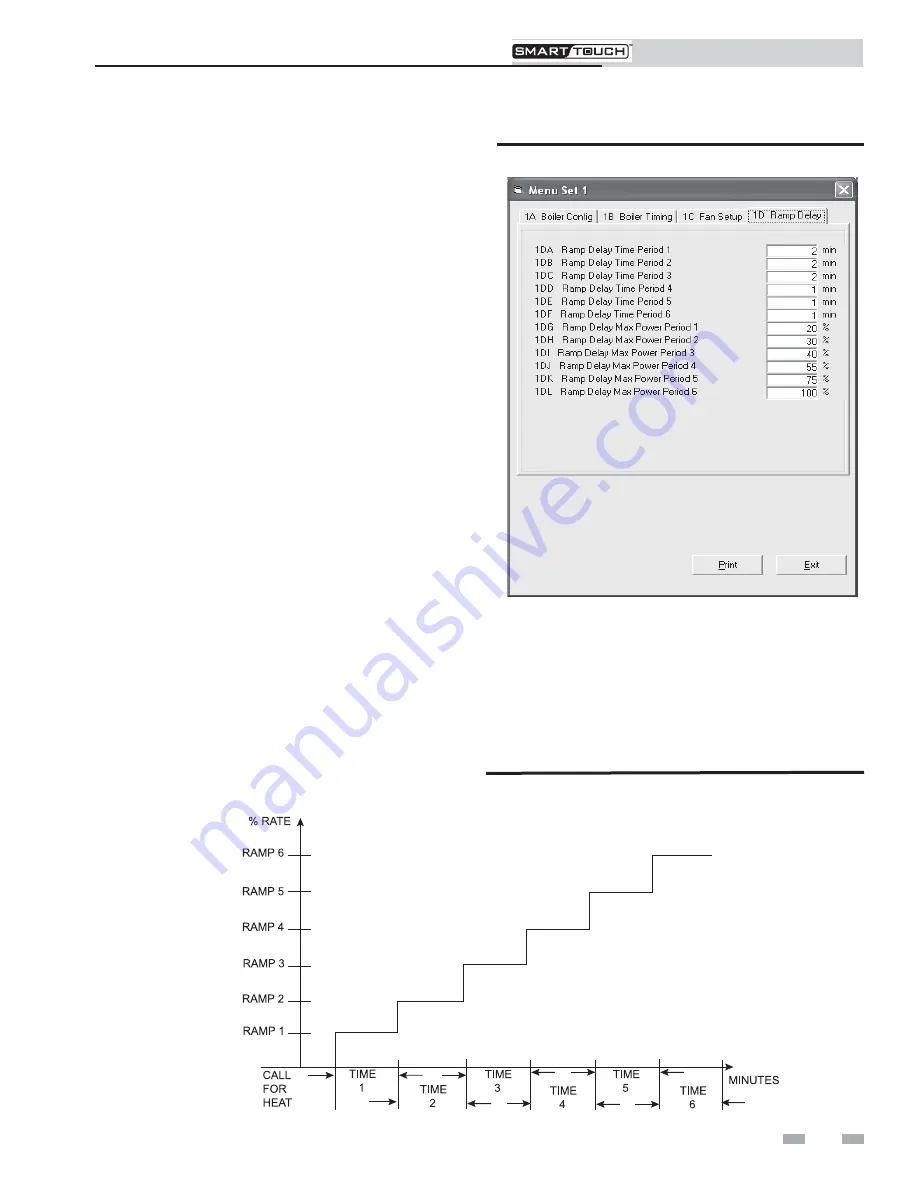

Ramp delay settings

When active, the ramp delay limits the boiler firing rate when

a SH cycle has started

*

. There are 6 limiting steps used to

limit temperature overshoot and short cycles (see FIG. 6-2).

This feature can be turned on or off depending on the

installation. The default condition for this feature is disabled.

It should only be needed when the flow through the heat

exchanger is very low, or the flow in the primary loop can be

less than the flow in the secondary loop. The time for each of

the 6 ramp delays as well as the power level for each of the 6

ramp delays are adjustable. The time range for each ramp

delay is adjustable from 1 minute to 40 minutes with the total

of all 6 ramp delays not to exceed 109 minutes. The default

delay time for Periods 1, 2, and 3 is 2 minutes. The default

delay time for Periods 4, 5, and 6 is 1 minute. This process can

also work in reverse when the boiler shuts off. After shutting

off, the max firing rate will be limited to the ramp 6 limit for

the period 6 time delay, then to the ramp 5 limit for the period

5 time delay, and so forth. This step down feature overrides

the step up feature until the ramp up limit becomes higher

than the ramp down limit. To access the Ramp Delay settings,

click on the tab labeled 1D Ramp Delay (see FIG. 6-2).

Figure 6-2

Parameter Set 1D

The power range for each ramp delay is adjustable from 0 to

100. The defaults for each ramp delay is ramp delay 1= 20%,

ramp delay 2=30%, ramp delay 3=40%, ramp delay 4=55%,

ramp delay 5=75%, ramp delay 6=100% (FIG. 6-3). Note that

the limit in period 6 will limit the firing rate throughout the

entire call for heat. The locations for these parameters are

1DG through 1DL. See parameter 4FE (page 17 of this

manual) to enable or disable the ramp delay feature.

Figure 6-3

Ramp Delay Interval

PC Program Instructions

*

This is recommended for single-boiler installations only.