PC Program Instructions

1

Installation

Program installation

There are two programs available for programming and

monitoring the SYNC boilers.

SITECS937Lab

is used to

monitor the operation of the boiler and program a few display-

related parameters

. SMART TOUCH PC

is used to program

the bulk of the parameters in the controls.

To begin installation of the programs, please insert your

SMART SYSTEM CD into the CD drive. If you have Autostart

enabled, the SMART SYSTEM software screen will load. If not,

navigate to CD drive and double-click on

index.html

. Once

the screen opens, select the program you wish to install. Follow

the prompts, and after all the desired programs are installed,

restart your computer.

If you wish to have the PC program icons on your desktop, click

on

START

, and then Programs. Right click on

SMART

TOUCH PC

. Place the cursor over

Send to >

, and then click on

Desktop

. Repeat this procedure for the

SITECS937Lab

program.

USB installation

Your PC will communicate with the SMART TOUCH control

through the USB cable included with your kit. This cable will

require a specific USB driver. This driver may be installed by

starting the SMART TOUCH PC program, clicking on the

Settings

pull-down menu, and clicking on the

Comport >

item. In the next menu, you will have the option of installing

one of two USB drivers. Select the option appropriate for the

operating system used by your PC. The necessary driver will

install automatically.

4.

Click on the

“Port Settings”

tab, then on the

“Advanced”

button. Select an unused Comport number

(preferably COM1) in the range of COM1 to COM16.

Click on

OK

. Click

OK

on the previous window and then

close all of the other windows.

5.

Restart your PC to make sure the new ComPort number is

active. When you attach the USB cable to the PC, the PC

should recognize the cable. The next time you start up the

SMART TOUCH PC and SITECS937Lab programs, click

on the “

Settings

” tab at the top of the screen, then click

on“

Comport

”. Select the ComPort number assigned to the

USB cable above.

The programs display temperatures in °F. If you wish to display

temperatures in °C, click on the

Settings

tab along the top of the

Main Screen window, and move the cursor over

Temperature

>

in the pull-down menu. A new menu will appear, click on

Celsius

.

CAUTION

DO NOT connect a phone line to any of

the phone jacks on the control board.

Program setup

The PC will assign a ComPort to your new adapter. You will

need to know the ComPort number it uses in order to tell the

SMART TOUCH PC program which one to communicate with:

1.

Click on the following:

-

Start

-

Control Panel

-

System icon

(use the Classic View)

-

Device Manager

button

You will see a list of the hardware on your PC.

2.

Double click on

“Ports (COM&LPT)”

. You will see an

entry called

“USB Serial Port (COM4)”

. The ComPort

number may be different on your computer but the

device description will be the same. The SMART

TOUCH PC program can communicate through Com-

ports 1 - If the Comport assigned by your computer is

avalue larger than what is available in the SMART

TOUCH PC program, you will need to manually reassign

the ComPort on your computer.

3. Go back to the “

Ports (COM & LPT)

” area referenced

and take note of any unused ComPort between COM1 to

COM16. Double click on the “

USB Serial Port

”.

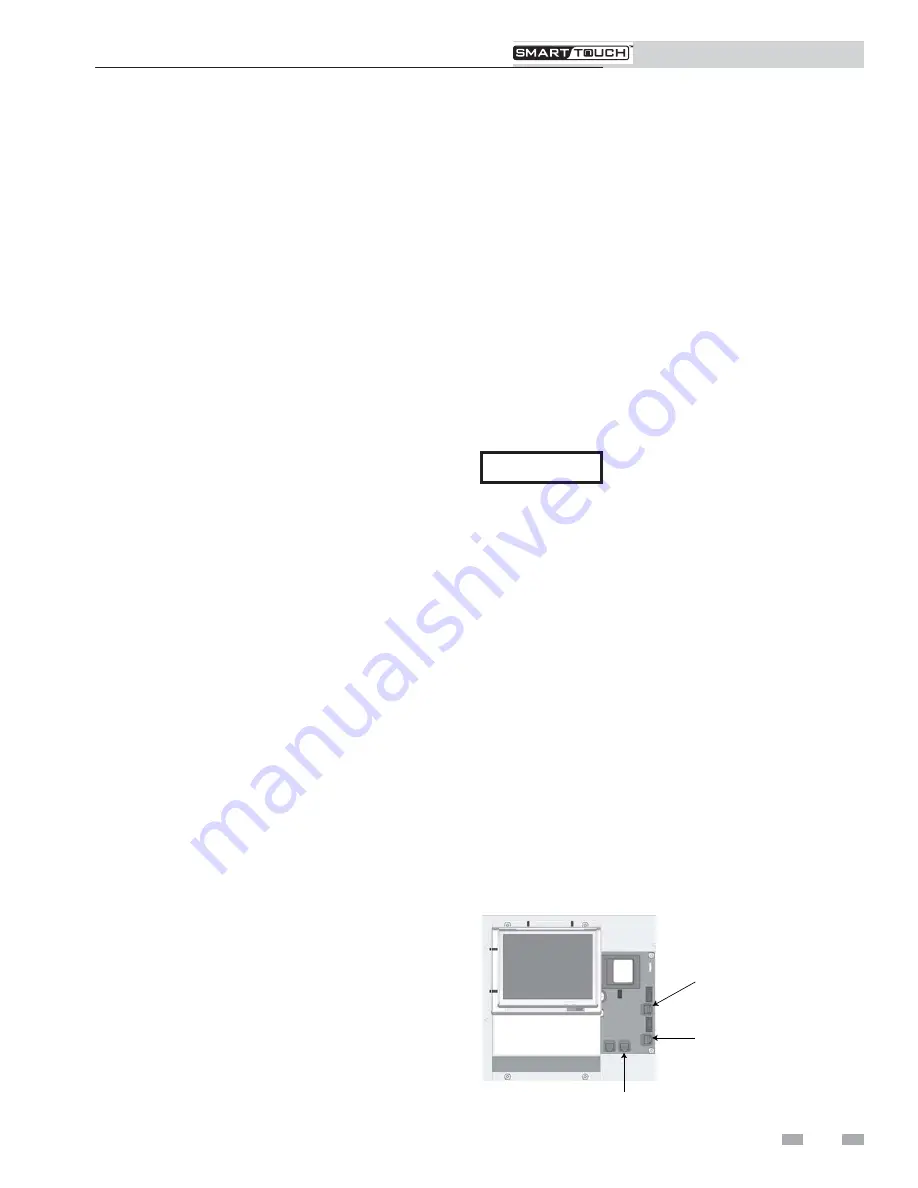

PC to Unit Connection

There are three connectors in which to plug the serial

communications cable on the SYNC unit (FIG. 1-a). Each one

is specific to a particular function.

PC Connection

The PC connection is used to monitor the unit performance,

data logging, programming the service provider’s name and

phone number, and setting selected display parameters. Use the

SITECS937Lab program for these functions.

PC1

The PC1 connection is used to retrieve, view, modify, and

restore parameters for controller 1. Use the SMART TOUCH

PC program for these functions.

PC2

The PC2 connection is used to retrieve, view, modify, and

restore parameters for controller 2. Use the SMART TOUCH

PC program for these functions.

PC1 CONNECTION TO VIEW AND

RESTORE PARAMETERS FOR

CONTROLLER 1.

PC2 CONNECTION TO VIEW AND

RESTORE PARAMETERS FOR

CONTROLLER 2.

PC CONNECTION FOR

MONITORING DATA LOGGING.

Figure 1-a

SMART TOUCH Cable Connections

3