8

4

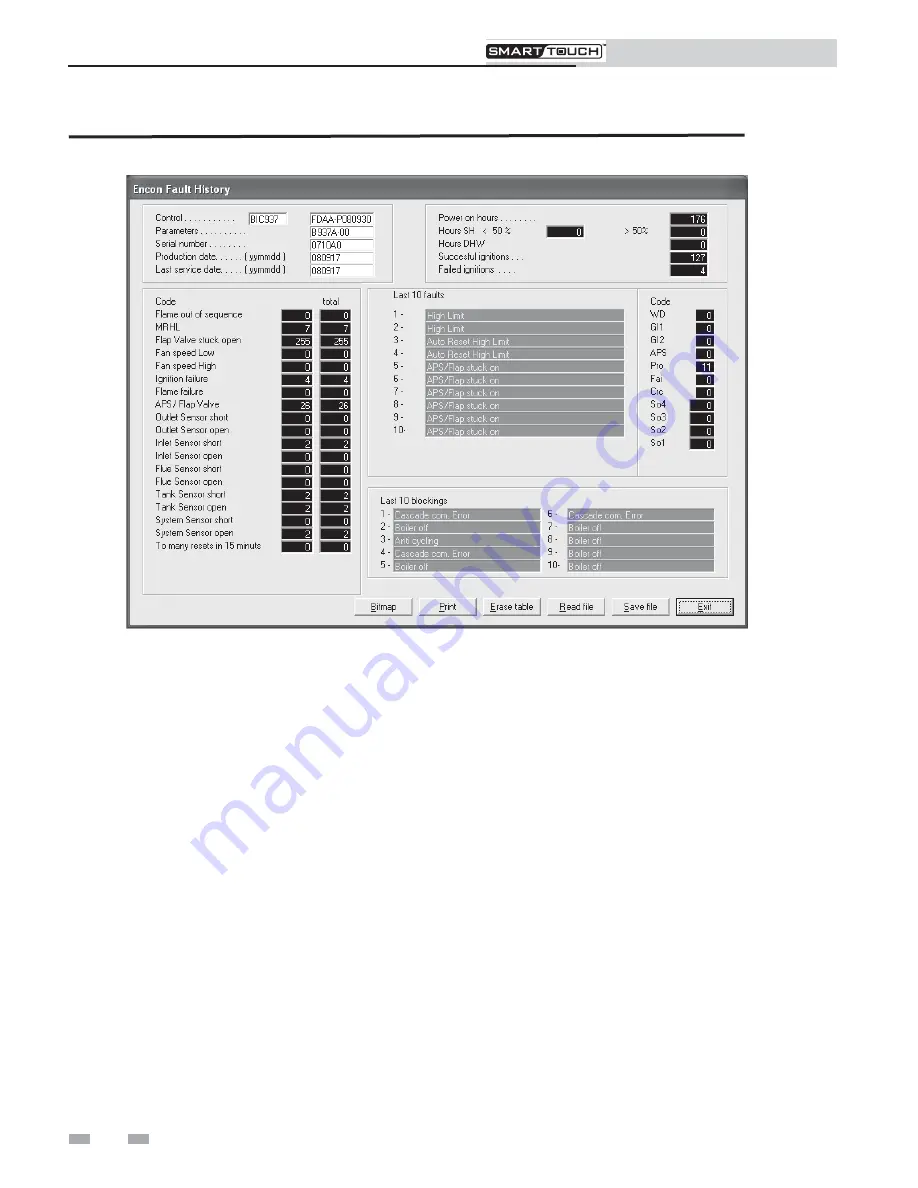

Fault History Screen

Figure 4-1

Fault History Screen

The Fault History Screen provides historical data about the

operation of the SMART TOUCH controls.. Click on the

Fault history

button along the top of the Main Screen

window (FIG. 1-1), and then click on

Read from Control

in

the pull-down menu. After uploading data from the selected

program, a window will appear with the status of numerous

counters and lists of the most recent events (see FIG. 4-1

above). Included are details of the control board serial

number, software version, default parameters, production

date, and last service date. The number of times various

faults have occurred is also shown. The last 10 faults are

listed, as well as the last 10 blockings (a blocking is an event

that causes the burner to shut off). In addition, the number

of hours the control has operated in various states is shown,

as well as the number of successful and failed ignition

attempts. Finally, a count of internal checks is shown.

The total number of occurrences of certain faults are also stored

in the control and shown on the left side of the screen. The

column on the right shows the total occurrences since the

control was built. The column on the left shows the total

occurrences since the table was reset. Press the

Erase table

button at the bottom of the window to clear the totals in the

column on the left. This will also clear the Last 10 faults and the

Last 10 blockings.

Some of this information may be needed by a service technician

to diagnose a problem, so provision is made to create a file in

which to save this data. Click on

Save file

, and define a file

name and the folder in which to save it. A bitmap can also be

saved by clicking on the

Bitmap

button at the bottom of the

Fault History Screen (FIG. 4-1). The bitmap file will be saved

to the folder ENCONFLS located below the file in which the

SMART TOUCH program resides.

PC Program Instructions