DU40•20 Technical Manual EN 150624

© 2015 www.Lock4Safe.com

Page 4 of 4

Now dial the factory code 10 20 30 40 on the

Change Index

5 x

Turn RIGHT, pass number “10” four times and stop exactly on the number on the

Changing Index

the fifth time.

4 x

Turn LEFT, pass second code number “20” three times and stop exactly on the

number on the

Changing Index

the fourth time.

3 x

Turn RIGHT, pass third code number “30” twice and stop exactly on the number

on the

Changing Index

the third time.

2 x

Turn LEFT, pass fourth code number “40” once and stop exactly on the number

on the

Changing Index

the second time.

When turning the dial, if a number is passed, start over at the beginning.

After the new Code is completely entered,

turn change key LEFT and remove it.

The new Code is

installed.

Try the new code several times (using Opening Index) before closing the door!

What if …

…accidentally the cam got moved before installation?

As long as the code has not been changed with the change key, the lock can be prepared for

mounting following the steps below:

1.

Hold the lock so that you look at the cover and the bolt is to the right.

2.

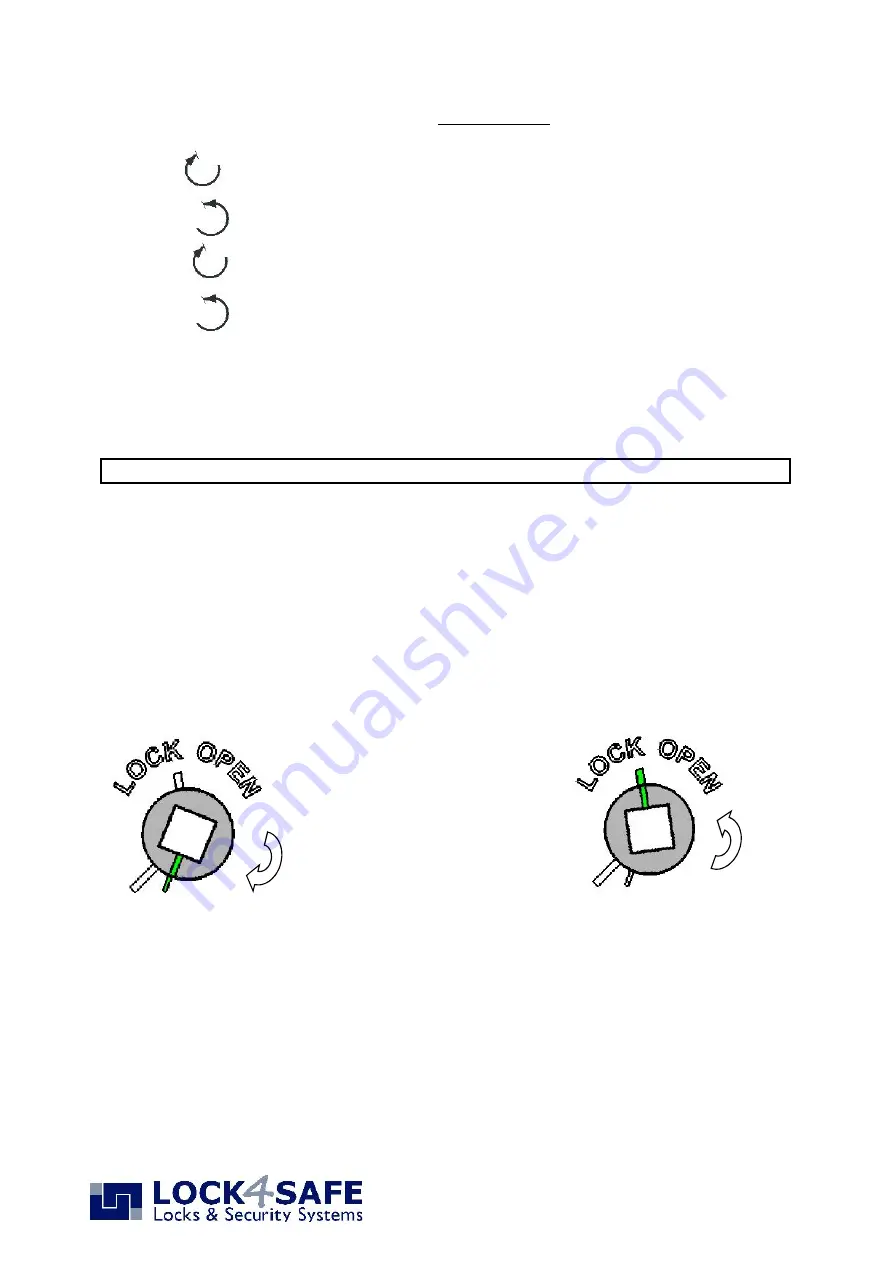

Turn the cam clockwise minimum 5 complete turns and stop when the cam is lined up as

shown in figure 1.

3.

Turn cam counterclockwise until lock opens. The cam should be lined up with the “LOCK

OPEN” line on the cover (see figure 2).

Do not deviate from this instruction as it is part of the VdS certification.

5x

Fig 1

Fig 2