Products and functions

YarnMaster PRISMA

www.loepfe.com

15

3.3

Functionality

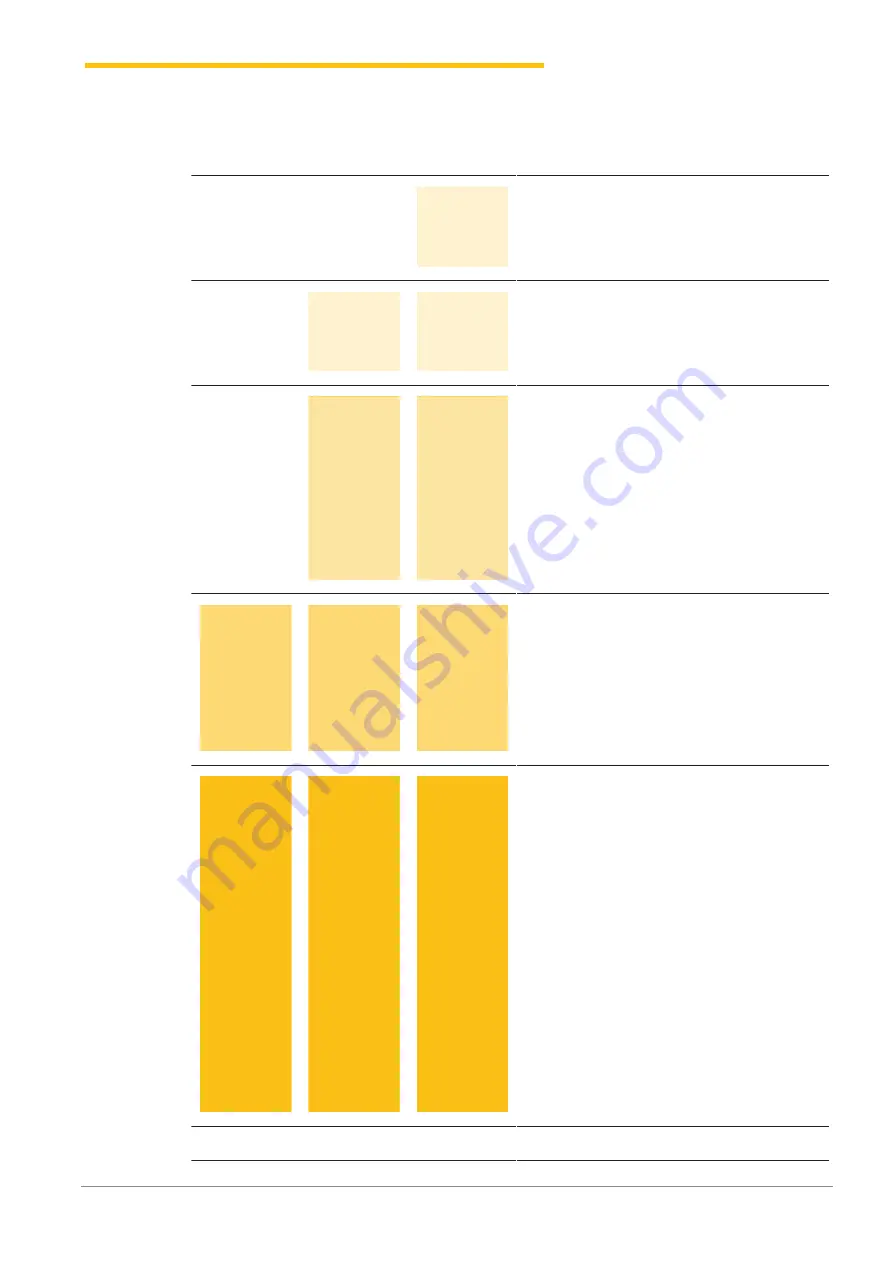

P clearing

n

Clearing and classification of synthetic foreign

matter (PP/PE/PES)

OffColor (option)

n

OffColor

– dark

– light

F clearing

n

Clearing and classification of foreign matter

– dark

– light

n

Organic Filter

n

Clearing of foreign matter clusters

– dark

– light

LabPack (Option)

n

SFI/D clearing and classification

– SFI/D short

– SFI/D long

n

SFI surface index

n

Imperfections

– IPI and IPI alarm

DM clearing

n

NSLT clearing

n

NSLT cluster clearing

n

Yarn count clearing

n

Short count clearing

n

Core clearing

– OffCentric Core

– Missing core

n

Splice clearing and classification

n

OffLimit alarm

n

Class alarm

n

Detection of OffStandard bobbins

PRISMA DM

PRISMA DMF

PRISMA DMFP