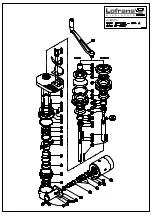

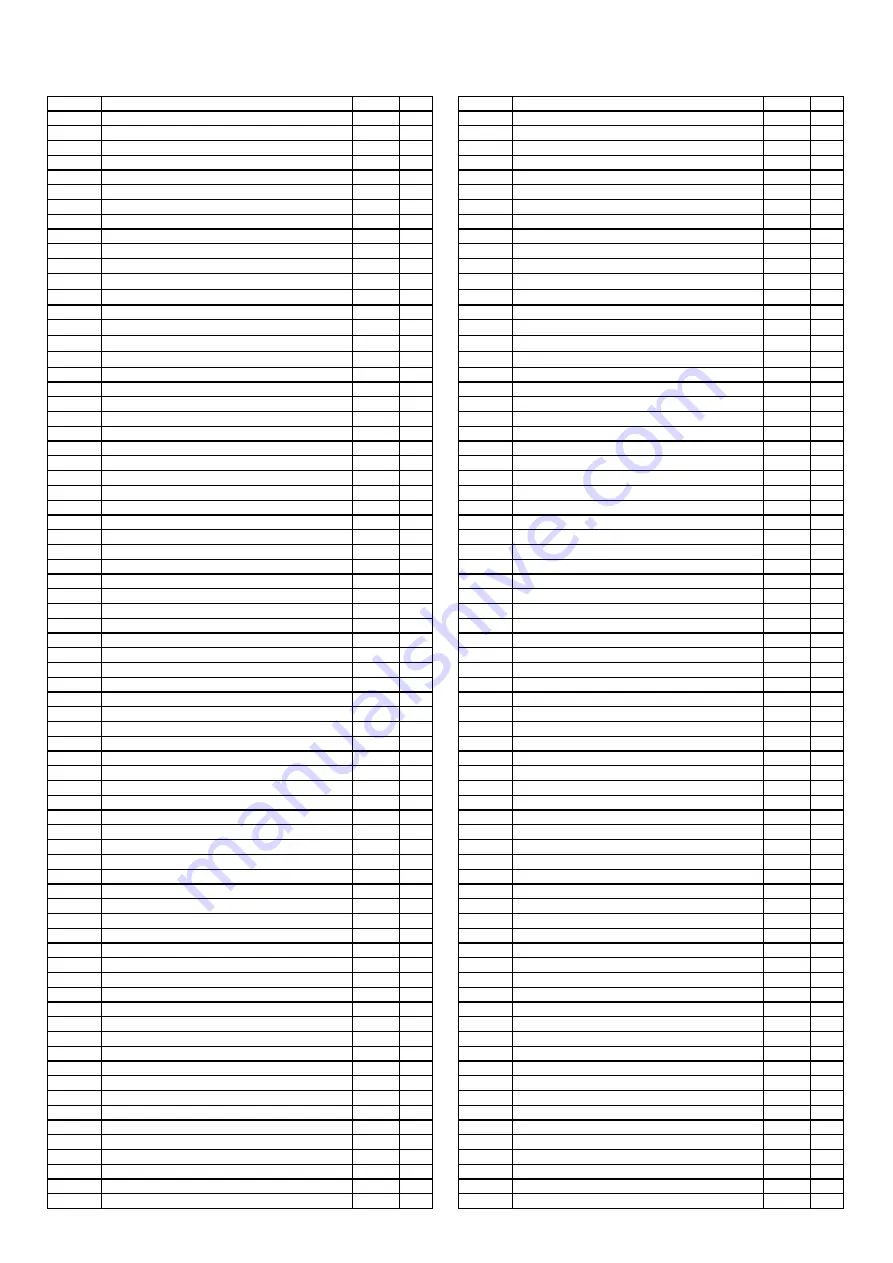

Item

Description

Kit

Q.ty

Item

Description

Kit

Q.ty

203

Seal - 35x45x7

Kit A

1

KA05101

Kit A - Seals

1

209

Key - 6x6x30

Kit C

3

KB05101

Kit B - Screw&Nuts

1

217

Hex hd screw M8x20

Kit B

2

KC05101

Kit C - Keys

1

226

Washer for screw M8

Kit B

6

KD05101

Kit D - Circlips

1

227

Nut - M8

Kit B

4

255

Key - 6x6x25

Kit C

1

272

Handle

1

273

Clutch nut

1

274

Drum

1

275

Washer

1

276a

Gipsy chain 6 Iso - Din 766

1

276b

Gipsy chain 7 Iso - 1/4" G40

1

276c

Gipsy chain 8 Iso - Din 766 - 5/16" BBB

1

276d

Gipsy chain 5/16 G40

1

276e

Gipsy chain 10 Iso - 3/8 G40

1

276f

Gipsy chain 3/8 Din 766 - 10 Din 766

1

276g

Gipsy chain 3/8 BBB

1

276h

Gipsy chain 3/8 PC

1

277

Clutch cone - inner

1

278

Seal - 25x47x7

Kit A

1

279

Circlip - 47 Din 472

Kit D

1

280

Circlip - 25 Din 471

Kit D

2

281

Bearing - 16005

1

282

Main shaft

1

283

Key - 6x6x80

Kit C

1

284

Key - 8x7x60

Kit C

1

285

Gipsy cap

1

286

Cone clutch

1

287a

Main shaft for gipsy type: a - b - c

1

287b

Main shaft for gipsy type: d - e - f - g - h

1

288a

Stripper for gipsy type: a - b - c

1

288b

Stripper for gipsy type: d - e - f - g - h

1

289

Cover

1

290

Base

1

291

Seal - 25x35x7

Kit A

1

292a

Stud - M8x75

4

293

Hex hd screw M5x16

Kit B

5

294

Gearcase - upper

1

295

O Ring seal - 4387

Kit A

1

296

Seal - 40x56x8

Kit A

1

297

Bearing - 16008

2

298

Circlip - 78 Din 472

Kit D

1

300

Sleeve

1

301

Spring

1

302

Dog clutch

1

303a

Wormwheel

1

304

Seal - 40x55x7

Kit A

1

305

Gearcase - lower

1

306

Nut - M6

Kit B

2

307

Spring washer for screw M6

Kit B

2

308

Washer for screw M6

Kit B

2

309

Bearing - 6203

1

310

Worm

1

311

Thrust bearing - 51105

1

312

Circlip - 43 Din 472

Kit D

1

313

Seal - 25x43x9

Kit A

1

314

Key - 5x5x15

Kit C

1

315a

Electric motor 700W 12V

1

315b

Electric motor 700W 24V

1

315c

Electric motor 1000W 12V

1

315d

Electric motor 1000W 24V

1

AIRON

B.05.101 Rev. A - Date: 01-2007