TOOLS AND MATERIALS

Drill

∅

9 mm (3/8”), Spanner 10 mm A/F - 13 mm A/F

REQUIREMENTS

Jig Saw, Power Drill , Silicone Sealant

The electric motor of the windlass is able to operate under spray conditions ; however , if submerged , it could be irreparably damaged.

The AIRON model is made by a top part , including drum (274) , gipsy (276) and base

(290), and an under deck part , the gearbox (305) and electric motor (315).

Check there are no under and over deck obstructions. Be sure there is ample room to

enable you to use the handle (272). In order to facilitate maintenance operations Lofrans

suggest to install the windlass on a removable panel fixed on the deck by bolts. Standard

maximum deck thickness is 40 mm (1 9/16”) ; for deck exceeding this thickness , please

consult your dealer. If the deck is too thin or inadequate , it will be necessary to use a

backing pad (plywood , timber ) of sufficient dimensions to spread the stress imposed

during recovery of chain.

To avoid electrolysis problems do not use stainless steel

pad as backing pad.

For boats of steel or aluminium , it is very important that top and

under deck parts are insulated from the deck with a non conductive gasket. It is essential

that top and under deck parts are fitted parallel ; in some cases a mounting pad may be

necessary. Incorrect alignment may result in extra load being imposed on the motor

causing loss of power and overheating with excess current consumption.

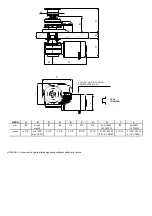

400 mm

The windlass must be placed where the chain locker has the max depth. The top part must

be located so that the chain runs parallel to the deck and turn around the gipsy with a

rotation of 180° approx. Ensure the chain locker is of sufficient capacity to store all the chain

and leave a minimum of 400 mm (16") between underside of the deck and the top of the

heaped chain. When the position of the windlass has been set , drill the necessary holes ,

using the template we supply. Separate top and under deck part loosening the nuts (227)

from the studs (292) and seal , using a good quality silicone sealant , the bottom of the base

and around the studs. Place the top part on the deck.

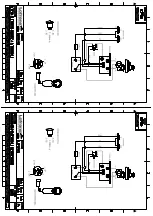

Under deck part may be oriented in the most suitable of four positions. Check that the

electric motor does not obstruct the run of the chain into the locker. Join the under deck part

to the top part inserting the key (284) of the main shaft into the key way of the gearbox. Tight

the nuts on the studs. Join the cables to the electric motor. Introduce the chain into the

gipsy , operate the "UP" switch of the foot switch or remote control and the chain will

automatically be fed into your locker. Take care to keep hands and feet well clear of

incoming chain. If the windlass runs in wrong direction , change over M1 and M2 cables at

the control box.

After using the windlass , we strongly recommend that the nuts are checked again to

ensure they are well tightened.

O

O

O

O P

P

P

P E

E

E

E R

R

R

R A

A

A

A T

T

T

T IIIIO

O

O

O N

N

N

N S

S

S

S

G

G

G

G B

B

B

B

WARNING ! = Do not approach with hands or feet near the gipsy and chain , when operating.

WARNING ! = When the windlass is not in use or before use the handle , turn off the windlass at the main switch .

WARNING ! = Engage the chain stopper after anchoring. Windlass must not be used as sole means securing anchor in bow fitting. Anchors

should be independently secured to prevent accidental release .

WARNING ! = Be sure the clutch and the chain stopper are well engaged before boating.

G

G

G

Giiiip

p

p

ps

s

s

sy

y

y

y C

C

C

Cllllu

u

u

uttttc

c

c

ch

h

h

h O

O

O

Op

p

p

pe

e

e

errrra

a

a

attttiiiio

o

o

on

n

n

n

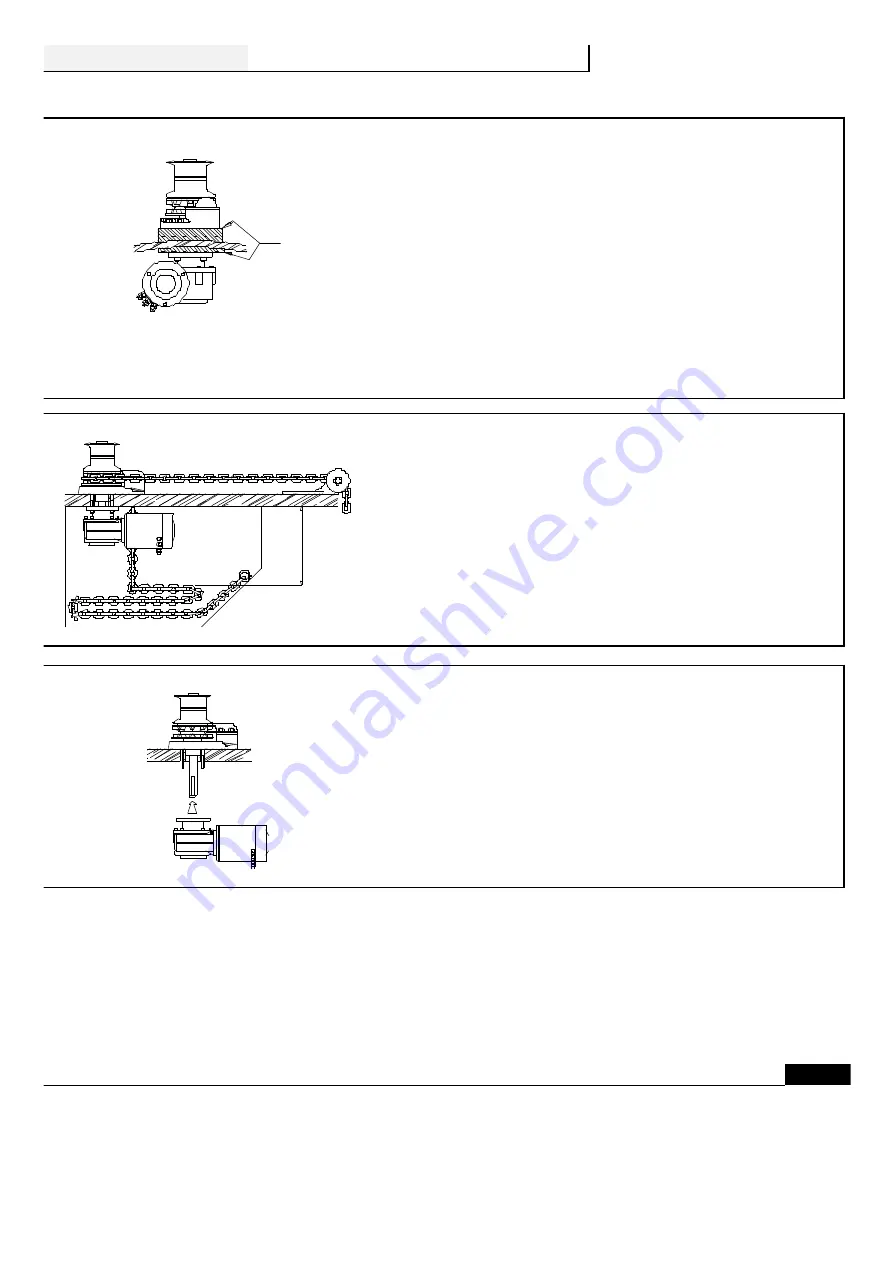

Gipsy is connected at the main shaft (282) or (287) by a clutch , items (275 and 277) or (286 and 277).

Parallel