41

Kwik Trim 53

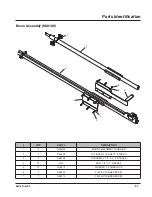

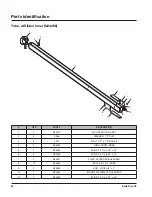

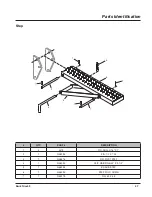

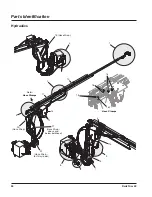

Parts Identification

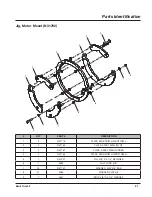

Jig, Motor Mount (N31760)

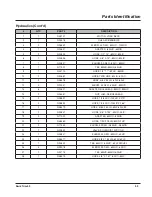

#

QTY.

PART #

DESCRIPTION

1

2

N31774

PLATE, KWIK TRIM JIG BOTTOM L

2

2

N31762

PLATE, KWIK TRIM JIG TOP

3

2

N31761

PLATE, KWIK TRIM JIG INNER

4

1

N31763

PLATE, KWIK TRIM JIG BOTTOM R

5

1

N31221

PIN, 3/8" X 2-1/4" RETAINER

6

7

4052

NUT, LOCK 3/8"

7

14

N31741

WASHER, FLAT 3/8" SAE

8

14

4064

WASHER, FLAT 3/8

9

7

4537

BOLT, 3/8" X 2-1/4" GRADE 5

1

2

3

4

2

5

9

7

8

8

1

7

6

Summary of Contents for Kwik Trim 53

Page 2: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 12: ...Kwik Trim 53 ...

Page 18: ...6 Kwik Trim 53 ...

Page 24: ...12 Kwik Trim 53 ...

Page 42: ...30 Kwik Trim 53 ...

Page 43: ...31 Kwik Trim 53 PARTS IDENTIFICATION AND HYDRAULIC SCHEMATICS Parts Identification ...

Page 75: ...63 Kwik Trim 53 This page intentionally left blank Parts Identification ...

Page 93: ......