Simplex Classic Mat Cutter

Instruction Manual

Model 550-1/560-1

7

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 847-526-5515

LoganGraphic.com

A

B

Changing Scales

Your Logan mat cutter is supplied with a separate set of either inch or metric

scales. If you prefer a different form of measurement than what is installed

on your mat cutter, use these simple steps to recalibrate your machine to the

alternate scale measurements.

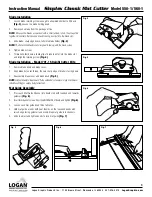

Switching inch scale to metric scale:

Step 1:

Using a pencil, mark a small line on the machine next to the 2 3/4” mark of

the inch scale

(Fig. 27)

. Mark the line on the machine itself, NOT the scale.

Step 2:

Carefully peel up and remove the inch scale and clean off any adhesive or

glue residue left behind.

Step 3:

Peel off the adhesive backing from the metric scale and apply it with the 7cm

mark exactly next to the pencil mark you drew. Conversion: 2 3/4” = 7cm

(Fig. 28)

.

Switching metric scale to inch scale:

Step 1:

Using a pencil, mark a small line on the machine next to the 7cm mark of

the metric scale

(Fig. 29)

. Mark the line on the machine itself, NOT the scale.

Step 2:

Carefully peel up and remove the metric scale and clean off any adhesive or

glue residue left behind.

Step 3:

Peel off the adhesive backing from the inch scale and apply it with the

2 3/4” mark exactlly next to the pencil mark you drew. Conversion: 7 cm =

2 3/4”

(Fig. 30)

.

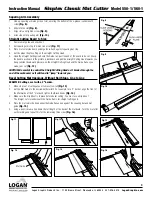

Re-Squaring the Squaring Arm

Tools needed: Screwdriver, Carpenter’s Square

Before making any adjustments to the squaring arm, make sure that the machine is

truly out of square, not the mat board, by using the squareness test.

ATTENTION: It is common for 32” x 40” sheets of mat board to be

un-square when bought. Take this into account before making any

adjustments to the squaring arm.

Squareness Test

1. Place the carpenter’s square against the right hand side of the guide rail and

down against the squaring arm

(Fig. 31)

. Lock to see if there are any gaps

between the framing square and the squaring arm. If so, the squaring arm

needs to be adjusted.

To Re-Square

1. By looking at where the gap is, you can determine which way the squaring arm

needs to go, in order to be square again.

2. Remove the squaring arm and locate the two screws inside of the slot.

3. To adjust, you must turn screws A & B in equal but opposite directions. To move

the far right end of the squaring arm towards the top end of the machine, turn

adjustment screw B inward (clockwise) about a quarter turn, and turn adjustment

screw A outward (counter-clockwise) a quarter turn

(Fig. 32)

4. Re-install the squaring arm and check for square. This is a trial and error

method. In some cases more than a quarter turn is needed, in some cases, less.

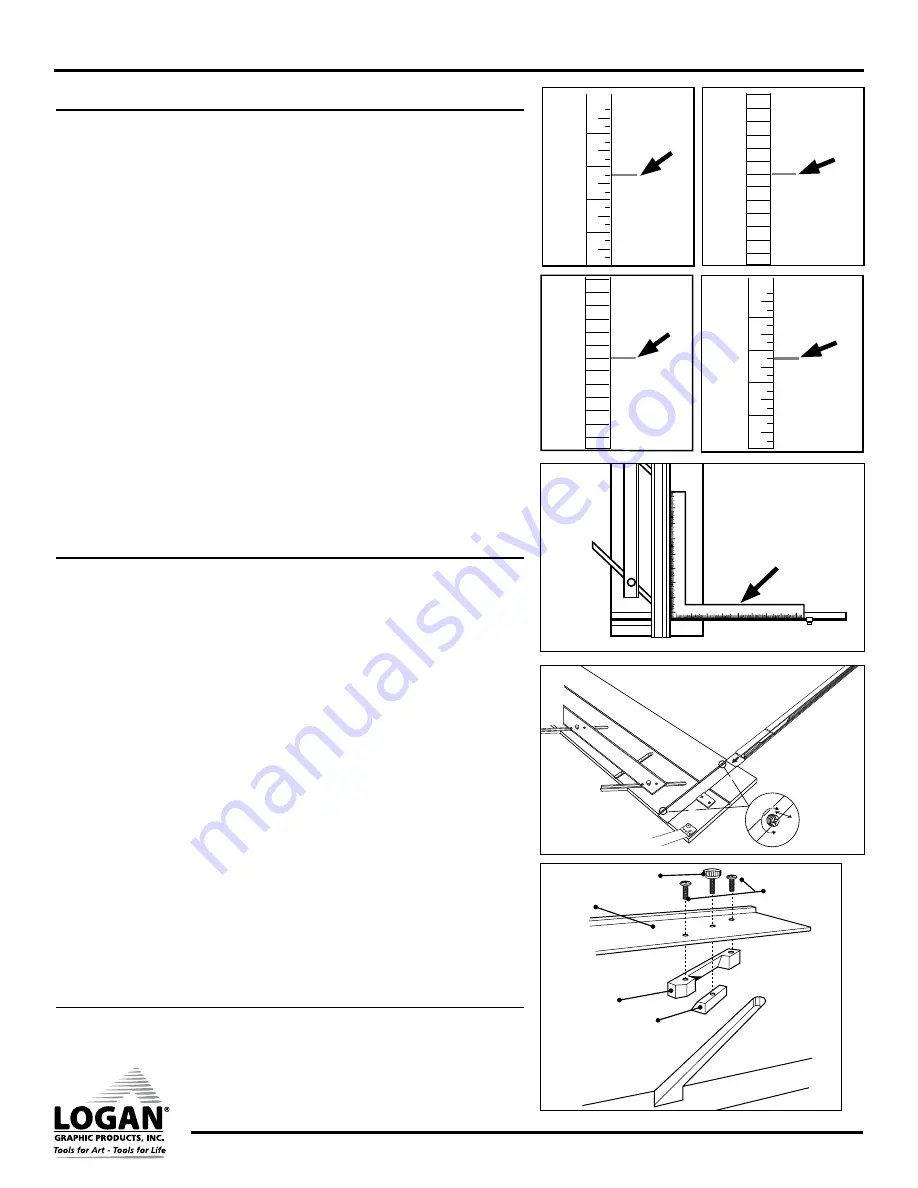

Mat Guide Assembly

If mat guide wedge becomes unscrewed from mat guide, reassemble making sure angle

of wedge is aligned correctly

(Fig. 33)

.

metric scale

1

3

5

7

inch scale

0

1

2

3

4

2

4

6

8

10

12

9

11

13

Mark a pencil

line on the

machine here

at 2 3/4”

metric scale

1

3

5

7

inch scale

0

1

2

3

4

2

4

6

8

10

12

9

11

13

Apply the metric

scale so the 7cm

mark aligns with

the pencil mark

metric scale

1

3

5

7

inch scale

0

1

2

3

4

2

4

6

8

10

12

9

11

13

Mark a pencil

line on the

machine here

at 7cm

metric scale

1

3

5

7

inch scale

0

1

2

3

4

2

4

6

8

10

12

9

11

13

Apply the inch

scale so the

2 3/4” mark

aligns with the

pencil mark

Fig. 27

Fig. 28

Fig. 29

Fig. 30

Mat Guide

#602 Slide

#603 Wedge

#604 Mat Guide

Screws (2)

#112N Mat

Guide Knob

Fig. 32

Fig. 31

Fig. 33

Place Square Here