L o g a n G r a p h i c P r o d u c t s I n c . , 1 1 0 0 B r o w n S t r e e t , Wa u c o n d a , I L 6 0 0 8 4 To l l F r e e 1 8 0 0 3 3 1 6 2 3 2 w w w. l o g a n g r a p h i c . c o m

10

FRAMER'S

EDGE

MAT CUTTER

MODELS 650, 655 & 660

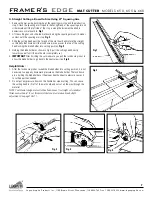

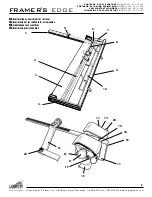

A. Blade Depth Adjustment - Bevel Cutter

NOTE: The depth setting of your Framer’s Edge is pre-set to cut U.S. Standard thickness

mat board. (.055” or 2.2mm)

To adjust the blade depth on the bevel cut, use the screwdriver provided and turn the

screwdriver in the slotted screw on the cutting head as shown. To decrease depth of the

bevel blade, turn the screw clockwise into the cutting head. To increase the depth of the

bevel blade, turn the screw counter-clockwise out of the cutting head.

Fig 1

It is always ideal to have just enough blade depth to slice through the mat you are

cutting and score slightly into the backing sheet. Extra blade depth can allow the blade

to flex resulting in hooks or curves in the cut. Extra blade depth can also cause the

blade to start its cut sooner and stop its cut later than needed resulting in overcuts.

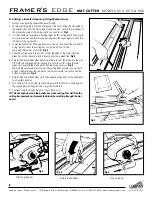

B. Blade Depth Adjustment to Cut 8-Ply Matboard

1. First remove the blade from the bevel blade holder.

2. Using the screwdriver supplied, tighten the small screw on the bevel blade holder

marked "8-ply setting"

.(Fig A)

3. Insert Logan 268 8-Ply Blade. Notice the blade has a bevel on only one edge. Be

careful to insert blade so bevel shows. Re-tighten the blade holding screw.

Note: #268 blade can only be used on one corner, bevel edge showing. It will not

operate properly installed with the opposite edge showing.

Fig 1

Fig A

Straight Depth

Adjustment Screw

Bevel Edge Depth

Adjustment Screw

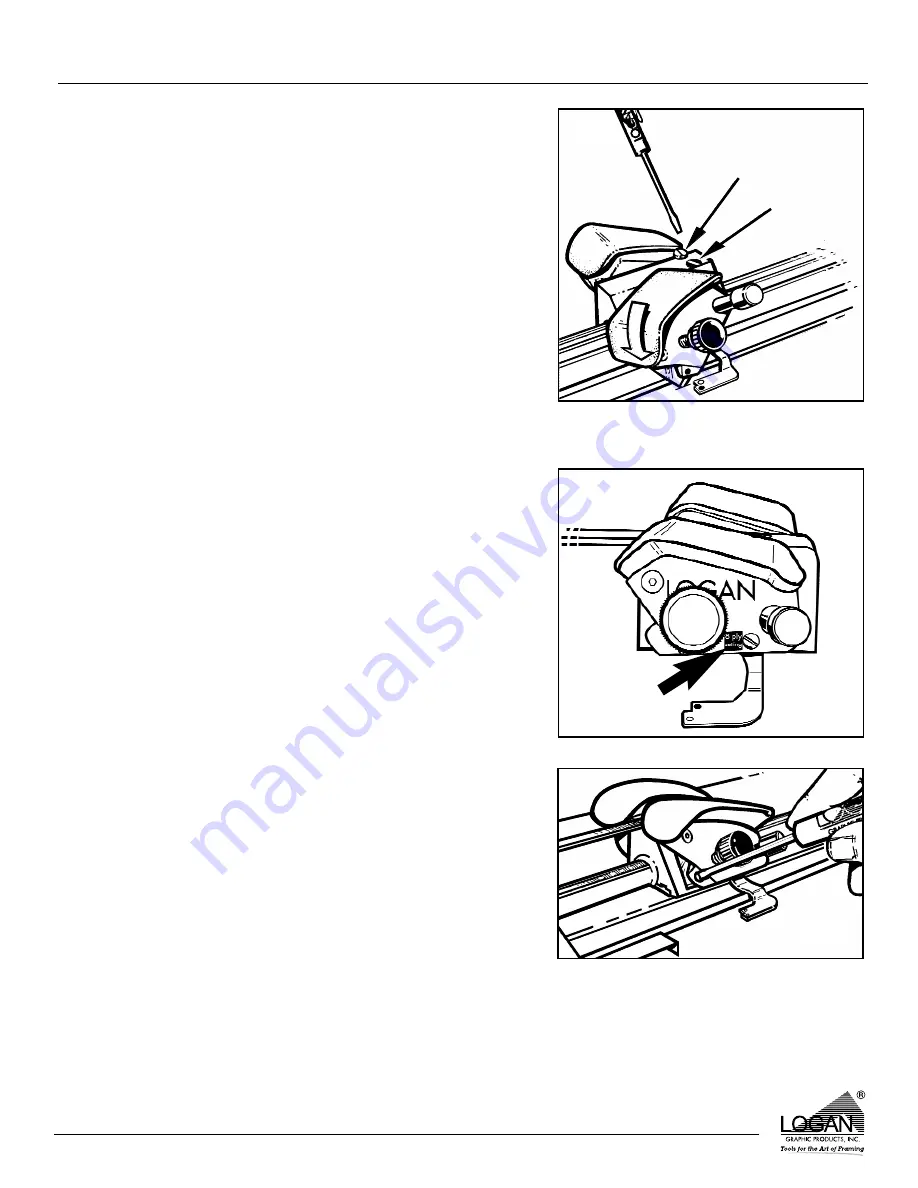

C. Blade Tip Adjustment

If curves in your bevel cut become a problem, it may warrant an adjustment to the blade

tip. At the end of the bevel blade holder nearest the tip of the blade you will find a

small blade tip adjustment screw. When adjusted this screw will put more pressure

against the blade tip causing it to ride closer to the cutting bar.

(Fig 2)

Do not turn this screw until you inspect the position of the blade tip in relation

to the edge of the cutting bar.

Ideally, the blade tip should just glide against the edge of the bar when activated. Raise

the handle bar and inspect this relationship by pivoting the blade holder down and

watching the blade tip as it passes by the edge of the cutting bar. If the blade tip is just

touching it, do not adjust the screw. If there is too much or too little contact between

the blade tip and the cutting bar then adjust the screw accordingly. Make only slight 1/4

turns on the screw and do test cuts to ensure accuracy.

Fig 2