Instruction Manual

Model F100-2

PRO SAW

1

Logan Graphic Products Inc., 1100 Brown Street, Wauconda, IL 60084 Toll Free 1 800 331 6232 www.logangraphic.com

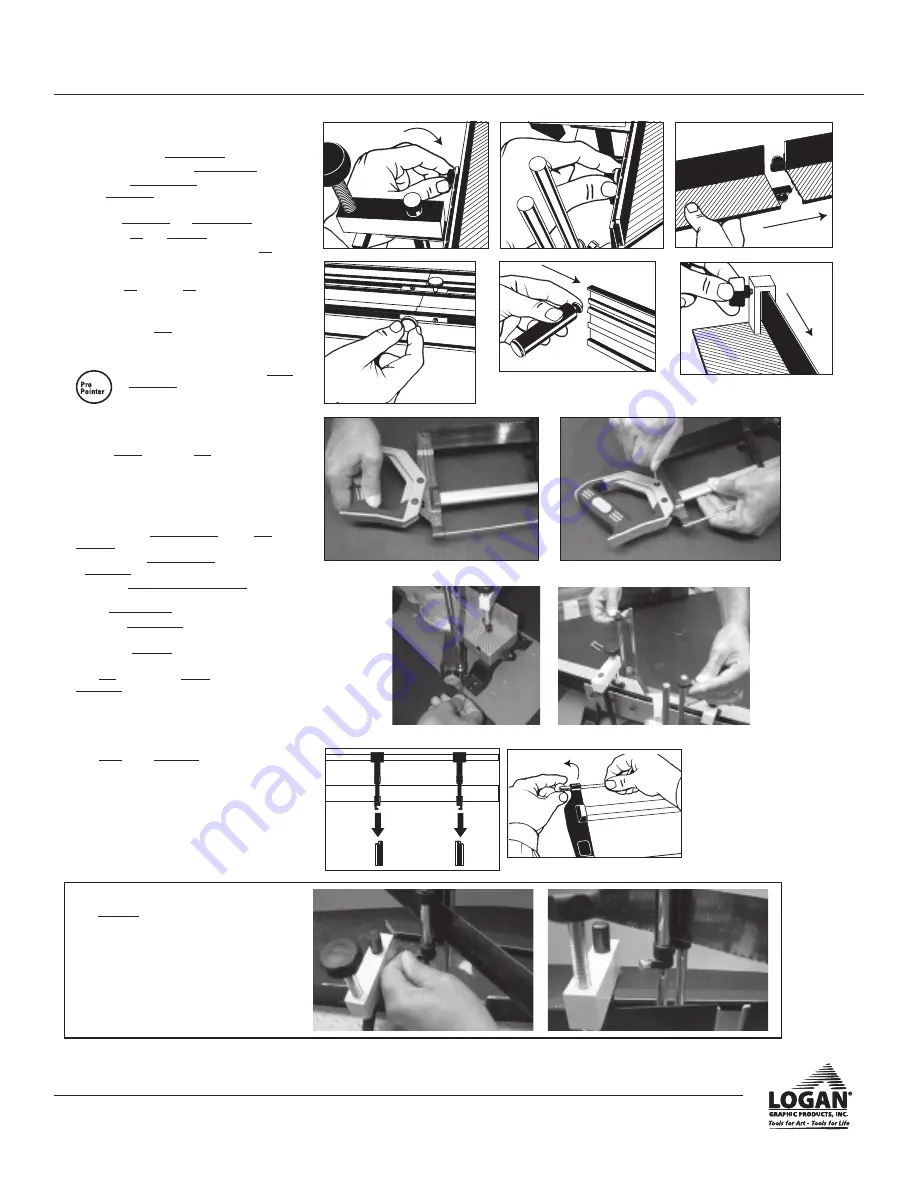

Fig. 6

Fig. 5

Assembly Procedure

A. Fence

1.

Tighten both rear thumb screws (Fig. 1 & 2).

2.

Repeat steps 1 and 2 for left hand fence.

3.

To attach extension fence, feed the fence section

into connectors extending from one another (Fig.

3).

4.

Tighten connectors with thumb screws (Fig. 4).

5.

To attach leg, turn saw base on it’s side.

6.

Loosen screw on support leg, then slide leg with

screw tab attached into channel of fence exten-

sion to the desired position (Fig. 5).

7.

Tighten leg by turning leg until secure.

B. Stop

1.

Slide moulding stop onto fence (Fig. 6).

2.

Tighten knob to lock.

Mounting-Optional

•

Mount base board to table using mount-

ing screws supplied. Drill 1/4” (6mm)

pilot holes for bolts.

C. Handle

1.

Be sure not to lose the two nuts.

2.

Slide handle onto end of saw and line up the bolt

holes (Fig. 6).

5.

Using Allen Wrench, tighten screws to secure

handle (Fig. 8).

D. Saw

1.

To insert the four saw guide posts into the saw

assembly:

a. Place the four saw guide posts into position on the

angle pivot.

b. Insert the guide post assembly screws with the

screwhead facing outward in the slot in front of

each saw guide post.

c. Using the Allen wrench, tighten the screw heads

(Fig. 9).

2.

To install the saw rests, slide one each onto both the

front right and back left guide posts (Fig. 10).

3.

Slide saw onto rods with handle onto same side as

angle pivot handle (Fig. 11).

E. Blade Changing

1.

Loosen tension knob but do not totally remove (Fig.

12).

2.

Slide blade free of guide bars.

3.

Reverse steps 1-3 for replacing with new blade.

Note: Be sure blade teeth are angled pointing away

from handle.

Fig. 1

Fig. 2

Fig. 4

Fig. 3

✔

Fig. 11

Fig. 12

Saw rests explained.

The saw rests are an added feature to raise the

saw out of the way while the moulding is being

positioned.

To use the rests, first raise the saw upward on the

guideposts. Next, slide the saw rests upward on

the guidepost into position and tighten the screw.

Fig. 7

Fig. 8

Fig. 10

Fig. 9