5

Tank installation

Logano G334X – 6 720 811 237 (2014/05)

11

5.4.2

Connect the central heating supply and return

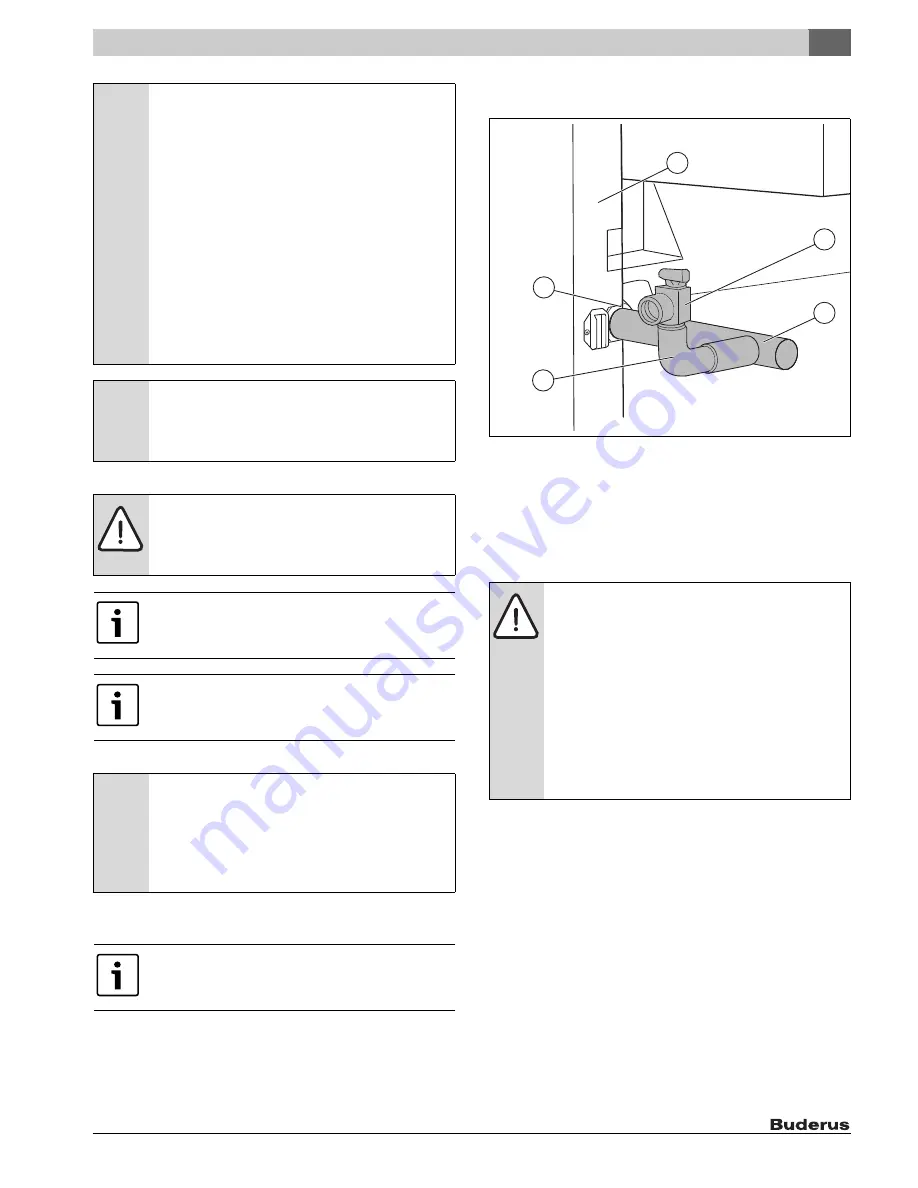

Connecting the safety valve in the central heating supply

▶ Install the included supply manifold and the 90° elbow.

▶ Do not install the safety valve until the leak test has been completed.

▶ Install the safety valve in accordance with the requirements of the

ANSI/ASME Boiler and Pressure Vessel Code, Section IV.

Fig. 11 Supply connection

[1]

Boiler

[2]

Safety valve

[3]

Supply manifold pipe (factory-installed)

[4]

90° elbow (¾ " NPT)

[5]

Supply connection

5.5

Electrical connections

The electrical connections to the boiler must conform to the locally

applicable regulations and the relevant requirements of the National

Electrical Code, ANSI/NFPA-70. In Canada the regulations of CSA C22.1

Canadian Electrical Code, Part 1, must be observed.

The boiler must be grounded in accordance with the regulations of the

relevant authorities or else the requirements of the National Electrical

Code, ANSI/NFPA-70.

NOTICE:

Risk of system damage due to excessive

temperature differences in the heating system!

▶ If the boiler is operated in conjunction with an air

conditioning system, it is essential to ensure that the

pipes for the refrigerant fluid are connected in

parallel with the boiler system by means of suitable

valves to prevent the refrigerant from entering the

boiler. This prevents refrigerant fluid from entering

the boiler.

▶ If the boiler piping is connected to the heating coils of

a hot-air heating system, these may be exposed to

the circulation of cool air. In this case, the boiler

piping must be equipped with a flow-control valve or

some other automatic system for preventing the

boiler water from circulating by gravity during the

cooling cycle.

NOTICE:

Risk of system damage due to leaking

connections!

▶ Connect pipes without stress to the boiler

connections.

DANGER:

Risk of fire from flammable materials!

▶ Maintain a clearance of 2 inches (51 mm) from pipes

carrying hot water and flammable walls in the

installation room.

We recommend installing a dirt trap and a dirt separator

(accessory) in the heating return connection to reduce

build-up of debris on the water side.

Observe the local regulations for connection of boiler

systems.

NOTICE:

Risk of system damage due to faulty safety

valve!

During the leak test, the safety valve can be damaged.

▶ Do not install the safety valve until the leak test

(

Chapter 5.8 Filling heating system and checking

for leaks, page 16) has been completed.

The safety valve must be installed in a vertical position.

DANGER:

Danger to life from electric shock!

▶ Carry out electrical work on the heating system only

if you are properly qualified for the work in question.

If you do not have the proper qualifications, have the

work done by a suitably qualified electrician.

▶ Observe the local regulations.

▶ Incorrectly terminated cables can result in faulty

operation and possibly dangerous consequences.

When making the power connection, follow the

circuit diagrams on page 36.

▶ When performing maintenance, label all connection

cables before disconnecting them.

1

2

3

4

5

6 720 806 028-17.1T

Summary of Contents for G334X

Page 38: ...10 Logano G334X 6 720 811 237 2014 05 38 Notes ...

Page 39: ...10 Logano G334X 6 720 811 237 2014 05 39 Notes ...

Page 40: ......